Conductive polymer/zinc oxide composite counter electrode and preparation method thereof

A conductive polymer and zinc oxide technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve the problems of poor adhesion and easy falling off, and achieve the effects of low sheet resistance, developed pore structure, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

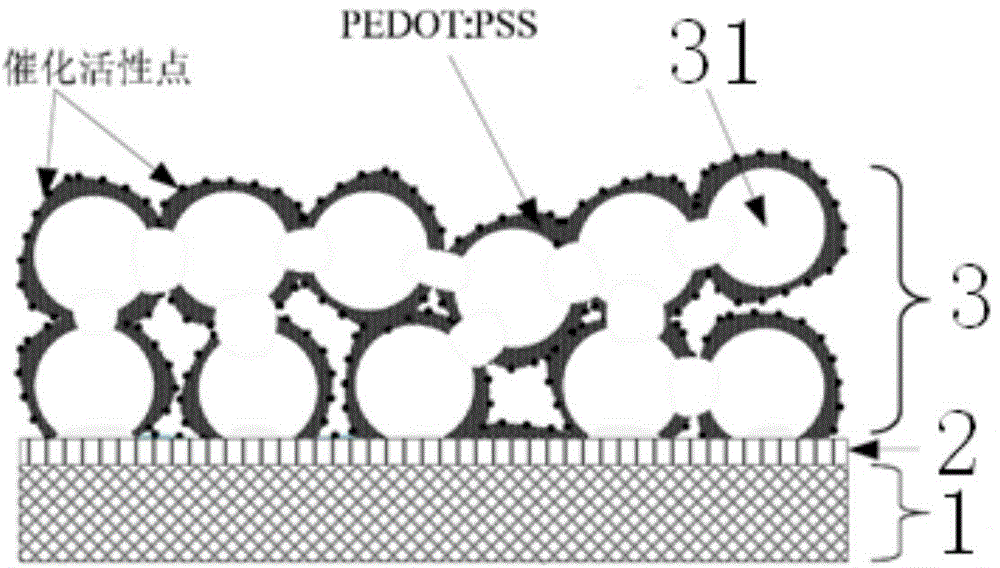

[0040] like figure 1 As shown, the present invention provides a conductive polymer / zinc oxide composite counter electrode, comprising a conductive substrate 1 covered with a zinc oxide layer 2 covered with a cross-linked pore structure The composite catalytic layer 3, wherein, the composite catalytic layer 3 includes a nanoporous zinc oxide film 31 and a layer of PEDOT:PSS (poly(3,4-ethylenedioxy) adsorbed on the surface of the nanoporous zinc oxide film Thiophene)-poly(styrenesulfonic acid)).

[0041] Wherein, the pores in the nanoporous zinc oxide film are fully open pore structures.

[0042] The thickness of the composite catalytic layer is 2-10 μm.

[0043] The zinc oxide layer is a dense zinc oxide layer, and the thickness of the dense zinc oxide layer is 10 nm˜1 μm.

[0044] The conductive substrate is any one of transparent conductive glass, metal substrate and carbon substrate.

Embodiment 2

[0046] The invention provides a method for preparing a conductive polymer / zinc oxide composite counter electrode, comprising the following steps:

[0047] 1) Glue compounding: according to the weight ratio of ethanolamine:zinc acetate dihydrate:ethylene glycol methyl ether=1:4.12:30, zinc oxide sol was obtained by stirring at 60°C;

[0048] 2) Coating film: the zinc oxide sol is deposited on the conductive substrate by spin coating;

[0049] 3) Heat treatment: heat preservation at 300°C for 0.5h in an air atmosphere to obtain a dense zinc oxide layer covering the conductive substrate;

[0050] 4) Mixing: uniformly mix zinc oxide mixed slurry by the weight ratio of nano zinc oxide particles: zinc oxide sol: polyethylene glycol 20000: water: triton=1:2:0.2:4:0.08;

[0051] 5) Coating: the zinc oxide mixed slurry is coated on the dense zinc oxide layer on the conductive substrate by scraping;

[0052] 6) Sintering: heat preservation at 450°C for 0.5h in an air atmosphere to obt...

Embodiment 3

[0062] The invention provides a method for preparing a conductive polymer / zinc oxide composite counter electrode, comprising the following steps:

[0063] 1) Glue compounding: according to the weight ratio of ethanolamine:zinc acetate dihydrate:ethylene glycol methyl ether=1:2:10, zinc oxide sol was obtained by stirring at 60°C;

[0064] 2) Coating film: the zinc oxide sol is deposited on the conductive substrate by spin coating;

[0065] 3) Heat treatment: heat preservation at 500°C for 0.1h in an air atmosphere to obtain a dense zinc oxide layer covering the conductive substrate;

[0066] 4) Mixing: uniformly mix zinc oxide mixed slurry by weight ratio of nano-zinc oxide particles: zinc oxide sol: polyethylene glycol 20000: water: triton=1:0.1:0.1:1:0.02;

[0067] 5) Coating: the zinc oxide mixed slurry is coated on the dense zinc oxide layer on the conductive substrate by scraping;

[0068] 6) Sintering: heat preservation at 300°C for 1 hour in an air atmosphere to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com