Super-lubricant antibacterial catheter and preparation method thereof

The technology of a urinary catheter and an antibacterial layer is applied in the field of ultra-smooth antibacterial urinary catheter and its preparation, which can solve the problems of inconvenient movement of patients, inconvenience of patients, and difficulty in insertion, and achieve the effect of reducing drug resistance and adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

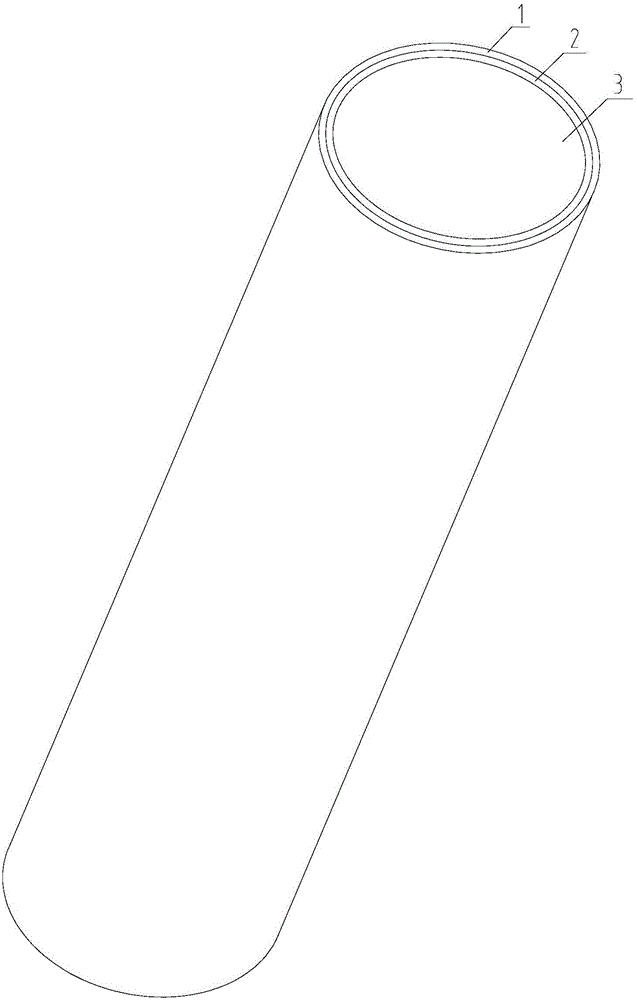

[0018] Example 1: Such as figure 1 The shown ultra-slippery antibacterial catheter includes a catheter body 3 , the surface of the catheter body 3 is coated with an antibacterial layer 2 , and the surface of the antibacterial layer 2 is coated with a lubricating layer 1 . The catheter body 3 is made of silica gel.

[0019] The preparation method of above-mentioned ultra-smooth antibacterial catheter comprises the steps:

[0020] (1) Prepare the following raw materials according to mass percentage: 0.5% chitosan, 10% propylene glycol, 10% glycerin, 0.2% sodium benzoate, 0.5% citrate, 0.3% essence, and the balance is purified water; the above raw materials are made into Emulsion and adjust the pH value to 5;

[0021] (2) Submerge the catheter body in the step (1) to prepare the emulsion, and stay for 1 minute to form an antibacterial layer;

[0022] (3) Immerse the catheter body obtained in step (2) in the liquid with a concentration of 2% hydroxypropyl cellulose, and stay ...

Embodiment 2

[0025] Example 2: The preparation method of above-mentioned ultra-smooth antibacterial catheter comprises the steps:

[0026] (1) Prepare the following raw materials according to mass percentage: 1% chitosan, 20% propylene glycol, 20% glycerin, 1% sodium benzoate, 1% citric acid, 0.8% essence, and the balance is purified water; the above raw materials are made into Gel and adjust the pH value to 6;

[0027] (2) Spray the gel prepared in the step (1) on the surface of the catheter body, the spray is even and the thickness is 2mm;

[0028] (3) Immerse the catheter body obtained in step (2) in the liquid with a concentration of 2% hydroxypropyl cellulose, and stay for 1 minute to form a lubricating layer;

[0029] (4) Dry the film formed after combining the antibacterial layer and the lubricating layer, and the drying temperature is 40°C;

[0030] (5) Use 625 mg / L ethylene oxide to sterilize the urinary catheter body obtained in step (4), the sterilization temperature is 53°C...

Embodiment 3

[0031] Example 3: The preparation method of above-mentioned ultra-smooth antibacterial catheter comprises the steps:

[0032] (1) Prepare the following raw materials according to mass percentage: 2% chitosan, 10% propylene glycol, 10% glycerin, 2% sodium benzoate, 2% citric acid, 1.5% essence, and the balance is purified water; the above raw materials are made into Gel and adjust the pH value to 7;

[0033] (2) Spray 10ml of the gel prepared in step (1) evenly on the surface of a catheter body;

[0034] (3) Put the catheter body obtained in step (2) in 3% hypromellose liquid, and stay for 2 minutes to form an antibacterial layer;

[0035] (4) Dry the film formed by combining the antibacterial layer and the lubricating layer, and the drying temperature is 50°C;

[0036] (5) Use 8555mg / L ethylene oxide to sterilize the catheter body obtained in step (4), the sterilization temperature is 56°C, the pre-vacuum degree is -25kPa, the sterilization time is 30min, and the steriliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com