Hemostatic non-viscous material and preparation method thereof

An anti-adhesion and hemostatic layer technology, applied in the field of medical materials, can solve the problems of poor anti-adhesion effect and hemostatic effect, etc., and achieve the effects of increasing the anti-adhesion effect, improving the mechanical strength, and increasing the hemostatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

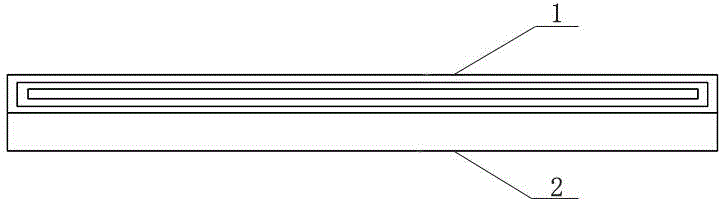

Image

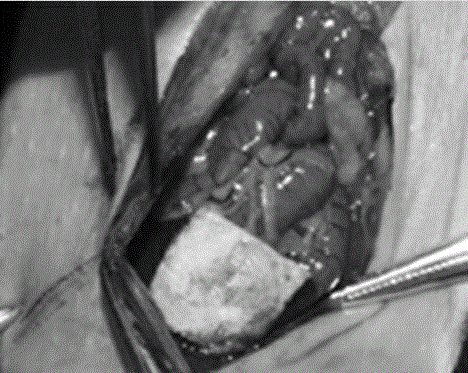

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of a hemostatic and anti-adhesion material, comprising:

[0040] performing an activated cross-linking reaction with the film-forming solution prepared from the first type of absorbable polymer material and an activator to obtain an anti-adhesion gel;

[0041] The anti-adhesion gel is wrapped layer by layer and dried sequentially to obtain an anti-adhesion layer;

[0042] Performing a complexing and crosslinking reaction on the film-forming solution prepared from the second type of absorbable polymer material and a complexing agent to obtain a hemostatic gel;

[0043] The hemostatic gel is formed into a film on the surface of the anti-adhesion layer, and then freeze-dried to obtain the hemostatic and anti-adhesion material.

[0044] In the preparation method provided by the present invention, in the step of preparing the anti-adhesion gel, the first type of absorbable polymer material is prepared into a 2-10% (w / ...

Embodiment 1

[0070] Take the preparation of chitosan-sodium carboxymethyl cellulose / small intestinal mucosa hemostatic and anti-adhesion film as an example.

[0071] Dissolve 2g sodium carboxymethylcellulose in 98g distilled water, stir and dissolve to obtain a 2% (w / w) sodium carboxymethylcellulose solution, then add 0.1% (w / w) 1-ethyl-3-( 3-Dimethylaminopropyl) carbodiimide hydrochloride (EDC), after activating at room temperature for 10 hours, forms a gel, washes repeatedly in ultrapure water for 10 times, and homogenizes;

[0072]The small intestinal mucosa was frozen at -30°C for 16 hours and then thawed at room temperature. Repeated freezing and thawing 3 times, after disinfection, placed in 1M NaCl and 0.5M HCl solution and repeatedly shaken for 10 hours to obtain decellularized small intestine Mucosal sublayer material;

[0073] Place the prepared small intestinal mucosal matrix sublayer material in the sodium carboxymethylcellulose solution for 2 hours, take it out, and leave it ...

Embodiment 2

[0078] Take the preparation of hydroxyethyl cellulose-polylactic acid / peritoneal hemostatic anti-adhesion film as an example.

[0079] After drying 5g of polylactic acid powder at 70°C, dissolve it in 95g of dichloromethane, stir vigorously to obtain a 5% (w / w) polylactic acid solution, and then add 0.8% (w / w) dimethylaminopropyl Ethylcarbodiimide (ETC), after being activated at room temperature for 5 hours to form a gel, placed in ultrapure water for 5 times and then homogenized;

[0080] The pig peritoneum was frozen at -80°C for 24 hours and then thawed at room temperature. Repeated freezing and thawing twice, after disinfection, placed in 0.5M NaCl and 0.1M NaOH solution and repeatedly shaken for 6 hours to obtain pig peritoneum Substratum material;

[0081] The prepared porcine peritoneal sublayer material was placed in the polylactic acid solution for 1 hour, then taken out, and left at room temperature for 1 hour, and this process was repeated 4 times;

[0082] Dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com