A kind of anti-algae wood-plastic composite material and preparation method thereof

A wood-plastic composite material and plastic matrix technology, which is applied in the field of algae-resistant wood-plastic composite material and its preparation, can solve problems such as algae hazards, achieve the effects of increasing roughness, good interface performance and mechanical properties, and increasing interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

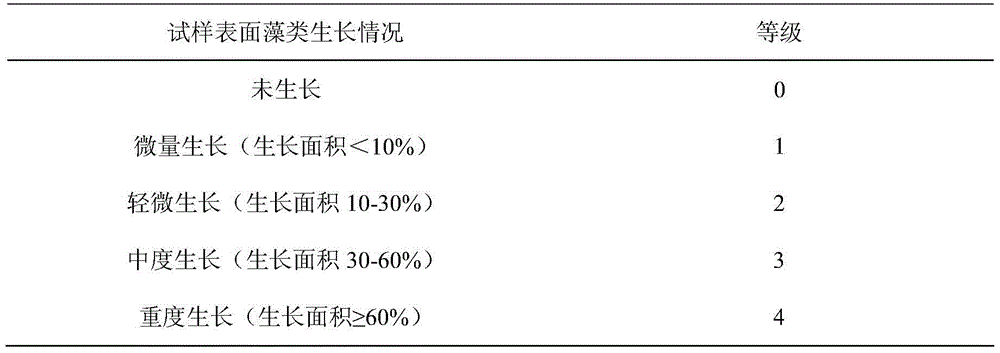

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Surface modification and grafting of lignocellulosic powder (wood flour): spray zinc pyrithione (ZPT) solution uniformly dispersed with absolute ethanol on the surface of 80 mesh wood flour, and the zinc pyrithione consumption is 1.0% of the wood flour quality , after stirring evenly, irradiating with 5kW power for 2min to obtain wood flour grafted with microwave-modified anti-algae active substances.

[0020] Preparation of anti-algae wood-plastic composite material: According to the ratio of parts by mass, weigh 100 parts of PP matrix, add 100 parts of wood powder grafted with microwave-modified anti-algae active substances into a high-speed mixer, and heat at 100°C, 700r / After stirring and mixing at high speed for 10 minutes under the condition of 10 minutes, add 15 parts of activated calcium carbonate, 2 parts of stearic acid, 2 parts of bisaminosilane coupling agent, 4 parts of light stabilizer, and 2 parts of toner, continue mixing for 10 minutes, and cool out Fe...

Embodiment 2

[0022] The surface modification grafting of lignocellulosic powder (bamboo powder): the carbendazim (MBC) solution that is uniformly dispersed with dehydrated alcohol is sprayed onto the surface of 40 order bamboo powder, and the carbendazim consumption is 1.5% of the bamboo powder quality, stirs After uniformity, microwave irradiation with 10kW power was used for 1.5min to obtain bamboo powder modified by microwave and grafted with anti-algae active substances.

[0023] Preparation of anti-algae wood-plastic composite material: According to the ratio of parts by mass, 100 parts of HDPE matrix was weighed, and 80 parts of bamboo powder grafted with microwave-modified anti-algae active substances were added to a high-speed mixer and heated at 90°C and 800r / After mixing at high speed for 10 minutes under the condition of 1 min, add 10 parts of activated calcium carbonate, 5 parts of PE wax, 4 parts of maleic anhydride grafted polypropylene, 2 parts of light stabilizer, and 2 par...

Embodiment 3

[0025] Surface modification grafting of lignocellulosic powder (flax powder): the thiabendazole (TBZ) solution uniformly dispersed with dehydrated alcohol is sprayed on the surface of 60 order flax powder, and the thiabendazole consumption is 2.0% of the flax powder quality, stirs After uniformity, it is irradiated with 15kW power for 1 min to obtain the flax powder grafted with microwave-modified anti-algae active substances.

[0026] Preparation of anti-algae wood-plastic composite material: According to the ratio of parts by mass, weigh 100 parts of HDPE matrix, add 60 parts of flax powder grafted with microwave-modified anti-algae active substances into a high-speed mixer, and heat at 110°C, 600r / After mixing at high speed for 15 minutes under the condition of 1 min, add 20 parts of activated calcium carbonate, 5 parts of PE wax, 5 parts of vinyl silane coupling agent, 3 parts of light stabilizer, and 3 parts of toner, continue mixing for 10 minutes, and then cool and disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com