Heat reflection and dissipation type automotive clear top finish

A technology of varnish and heat dissipation, applied in the field of automotive varnish, can solve the problems of no anti-heat function and unsatisfactory use effect, and achieve the effects of strengthening the three-dimensional effect, reducing oil consumption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3

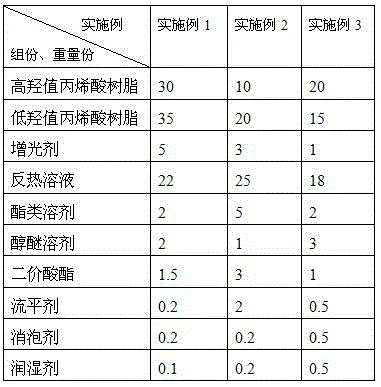

[0025] Embodiment 1-Embodiment 3: A heat-reversing and heat-dissipating type automotive finish paint, its components and parts by weight are as attached in Table 1.

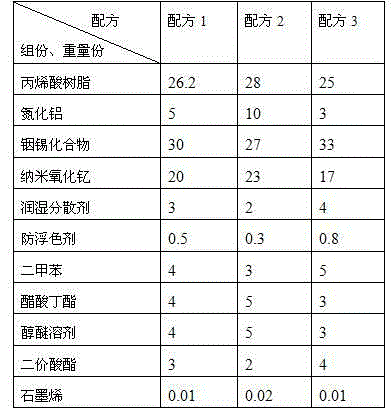

[0026] Schedule I

[0027]

[0028] In Attached Table 1, the brightener is a commercially available polyester resin additive. The composition and parts by weight of the anti-heat solution are formulated as any formula in the attached table 2, the ester solvent is xylene, the alcohol ether solvent is CAC (ethylene glycol ethyl ether acetate), dibasic acid The ester is DBE (dibasic acid ester mixture), the leveling agent is BYK306 leveling agent, the defoamer is siloxane such as BYK141, and the wetting agent is BYK163 wetting and dispersing agent. The high hydroxyl acrylic resin refers to the acrylic resin with a hydroxyl content of 3-4%, and the low hydroxyl value acrylate refers to the acrylic resin with a hydroxyl content of 1-2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com