Method and device for preparing ultrahigh-vacuum spin-polarized scanning tunneling microscope probe

A technology of scanning tunneling and ultra-high vacuum, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve the problems of increased difficulty of spin-polarized probes, and achieve spin-polarized scanning Tunneling microscopy, effect of low growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

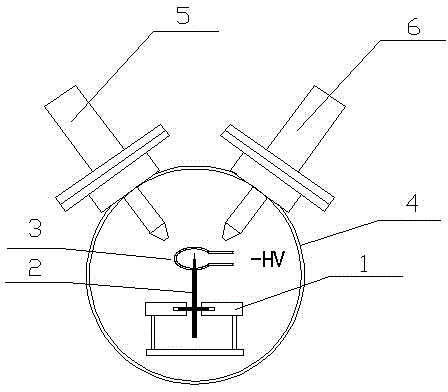

[0024] The device involved in the present invention includes: a tip frame of a scanning tunneling microscope probe; an electron beam heating ring; one or two molecular beam epitaxy evaporation sources for growing magnetic metal thin films; a crystal oscillator thickness gauge for real-time The thickness of film growth is monitored and controlled. The whole device can work in the environment of high vacuum and ultra-high vacuum. Specific examples figure 1 Shown: a needle tip holder 1, an electron beam heating ring 3, two molecular beam epitaxy evaporation sources, Gd evaporation source 5 and Fe evaporation source 6, the evaporation source is used to grow magnetic metal films, and the needle tip holder 1 is used to fix the needle tip 2 , the electron beam heating ring 3 is located at the upper end of the needle tip 2, the Gd evaporation source 5 and the Fe evaporation source 6 are installed toward the needle tip 2, and the needle tip holder 1, the needle tip 2, the electron bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com