Manufacturing method for annular magnetic random access memory unit structure

A technology of random access memory and manufacturing method, which is applied in the manufacture/processing of electromagnetic devices, photoengraving process of pattern surface, instruments, etc., can solve the problem of large size of MRAM cell, low memory density, and inability to apply magnetic random access memory and other issues to achieve cost savings, fewer sidewall processes and etching process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

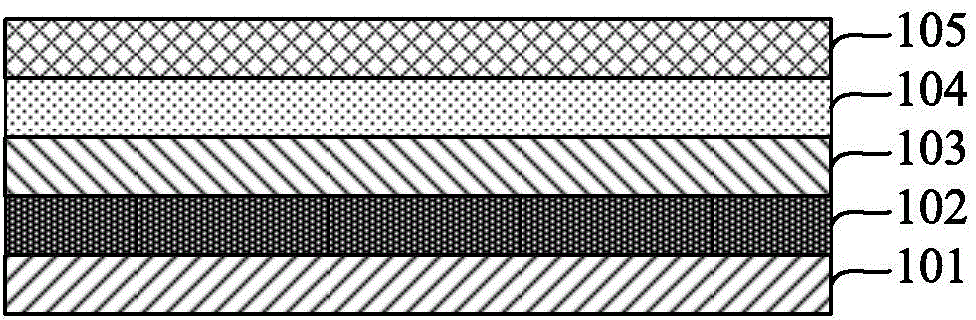

[0032] The hard mask layer (105) is silicon nitride, silicon dioxide, nitrogen-free oxycarbide film (NFC), nitrogen-doped silicon carbide (NDC), black diamond (BD), or any reasonable combination thereof.

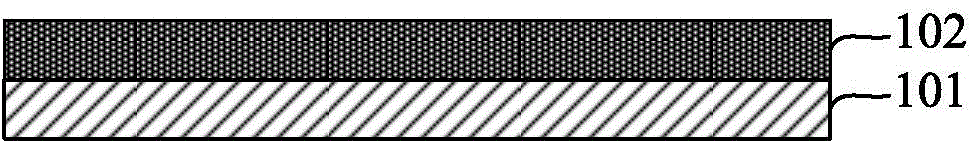

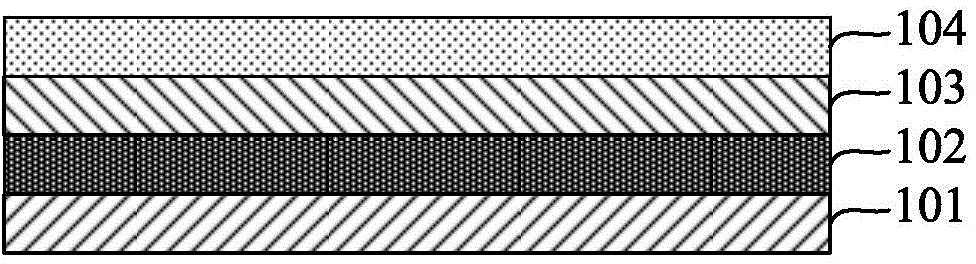

[0033] In the present invention, after the bottom electrode / magnetic tunnel junction / top electrode (BE / MTJ / TE) layers are deposited on the semiconductor substrate, a hard mask layer is deposited. The hard mask layer can be insulating materials such as silicon nitride, silicon dioxide, nitrogen-free carbon oxide film (NFC), nitrogen-doped silicon carbide (NDC), black diamond (BD), or any reasonable combination. After the positive photoresist is spin-coated and exposed, the wafer is developed twice to complete the ring-shaped pattern. The first development is a positive tone aqueous developer (positive tone aqueous developer), and the second development is a negative organic developer. liquid (negative tone organic developer). The positive aqueous developer detects the solub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com