Carbon fiber/carbon nanotube composite membrane as well as preparation method and application thereof

A carbon nanotube composite and carbon nanotube technology, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of limited application and complicated preparation methods, so as to simplify the preparation process, improve the uniformity of dispersion, Ease of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

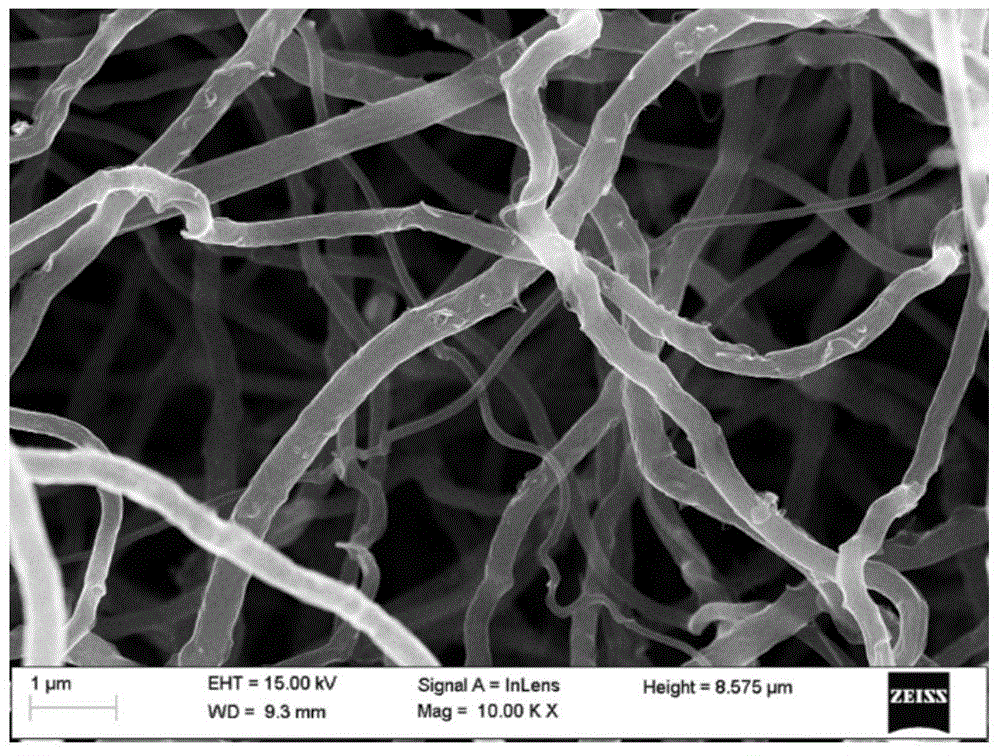

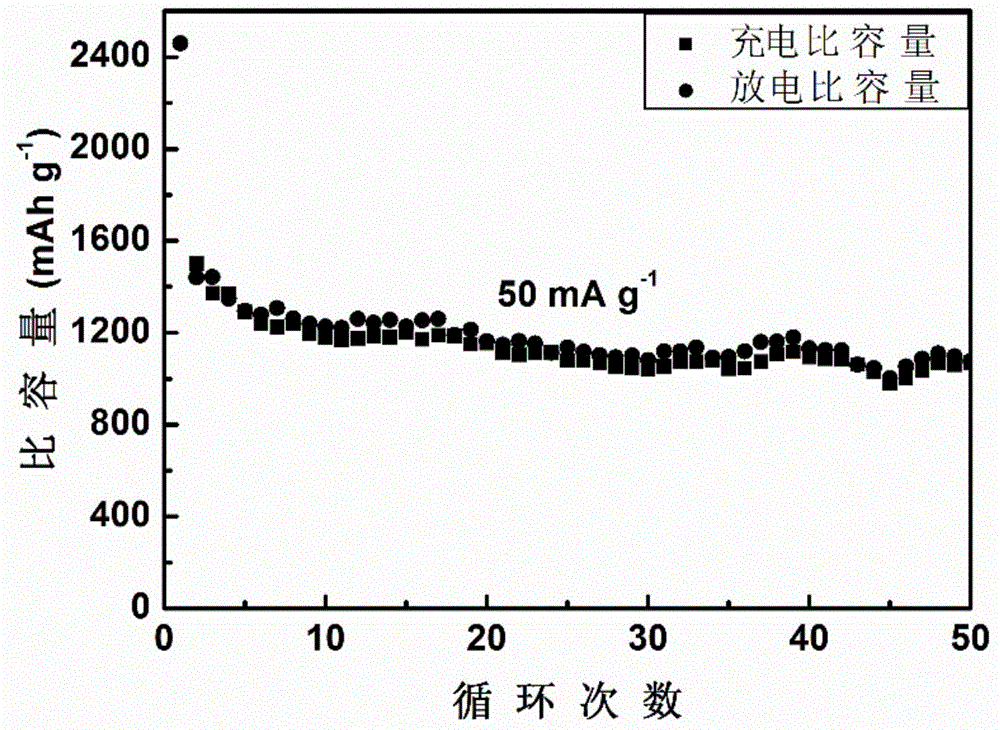

[0057] Add polyacrylonitrile with a molecular weight of 150,000Da to the organic solvent N,N-dimethylformamide, heat to a temperature of 60°C and stir under magnetic stirring until the polyacrylonitrile is completely dissolved to obtain a 10% mass fraction of polyacrylonitrile solution; then Add 5% carbon nanotubes by weight of polyacrylonitrile into the polyacrylonitrile solution, continue to stir for 24 hours, and then electrospin the solution to obtain the polyacrylonitrile / carbon nanotubes. The parameters of electrospinning are set as follows : The applied voltage is 15kV, the solution propulsion speed is 0.5mL / h, the fiber collection distance is 15cm, and the flat plate is used to collect; the obtained polyacrylonitrile / carbon nanotube composite film is pre-oxidized at a temperature of 280°C for 3h in an air atmosphere, Then carbonize at a temperature of 900°C for 3 hours in a nitrogen atmosphere to obtain a carbon fiber / carbon nanotube composite film with a diameter of 0....

Embodiment 2

[0062] Add polyacrylonitrile with a molecular weight of 150000Da to the organic solvent N,N-dimethylformamide, heat to a temperature of 30°C and stir under magnetic stirring until all polyacrylonitrile is dissolved to obtain a polyacrylonitrile solution with a mass fraction of 7%; then Add 20% carbon nanotubes by weight of polyacrylonitrile into the polyacrylonitrile solution, continue stirring for 30 hours, then electrospin the solution to obtain the polyacrylonitrile / carbon nanotubes, and the electrospinning parameters are set as follows: The applied voltage was 12kV, the advancing speed of the solution was 0.1mL / h, and the fiber collection distance was 10cm, and collected by a roller; the obtained polyacrylonitrile / carbon nanotube composite film was pre-oxidized at 200°C for 0.5h in an oxygen atmosphere, Then carbonize at a temperature of 600° C. for 1 h under a nitrogen atmosphere to obtain a carbon fiber / carbon nanotube composite film with a diameter of 0.3-2 μm.

[0063]...

Embodiment 3

[0067] Add polyacrylonitrile with a molecular weight of 150000Da to the organic solvent N,N-dimethylformamide, heat to a temperature of 40°C and stir under magnetic stirring until the polyacrylonitrile is completely dissolved to obtain a polyacrylonitrile solution with a mass fraction of 8.5%; then Add 10% carbon nanotubes by weight of polyacrylonitrile into the polyacrylonitrile solution, continue stirring for 10 hours, then electrospin the solution to obtain the polyacrylonitrile / carbon nanotubes, and the electrospinning parameters are set as follows: The applied voltage is 20kV, the solution propulsion speed is 0.8mL / h, the fiber collection distance is 20cm, and the rollers are used to collect; the obtained polyacrylonitrile / carbon nanotube composite film is pre-oxidized at a temperature of 220°C in an air atmosphere for 6h, and then Carbonize at 800° C. for 12 hours in a nitrogen atmosphere to obtain a carbon fiber / carbon nanotube composite film with a diameter of 1-5 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com