Metal/metal oxide/g-C3N4 composite photocatalytic material and preparation method thereof

A composite photocatalysis, g-c3n4 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photocatalytic efficiency, hindering development and application, poor electrical conductivity, etc. Enhanced photocatalytic activity, low synthesis cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

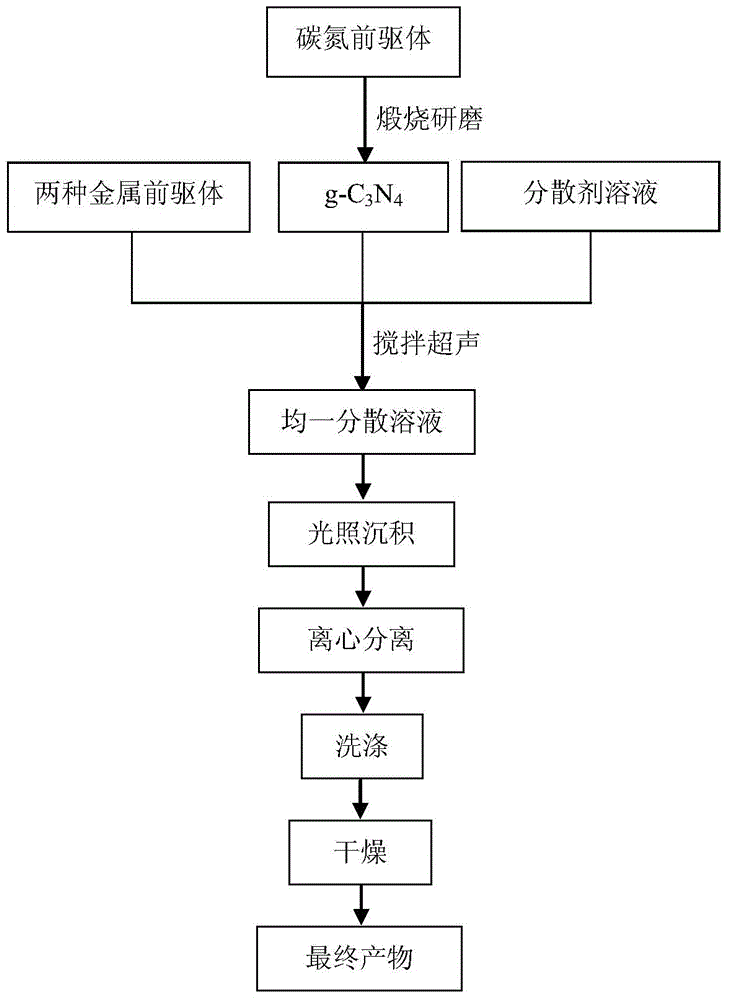

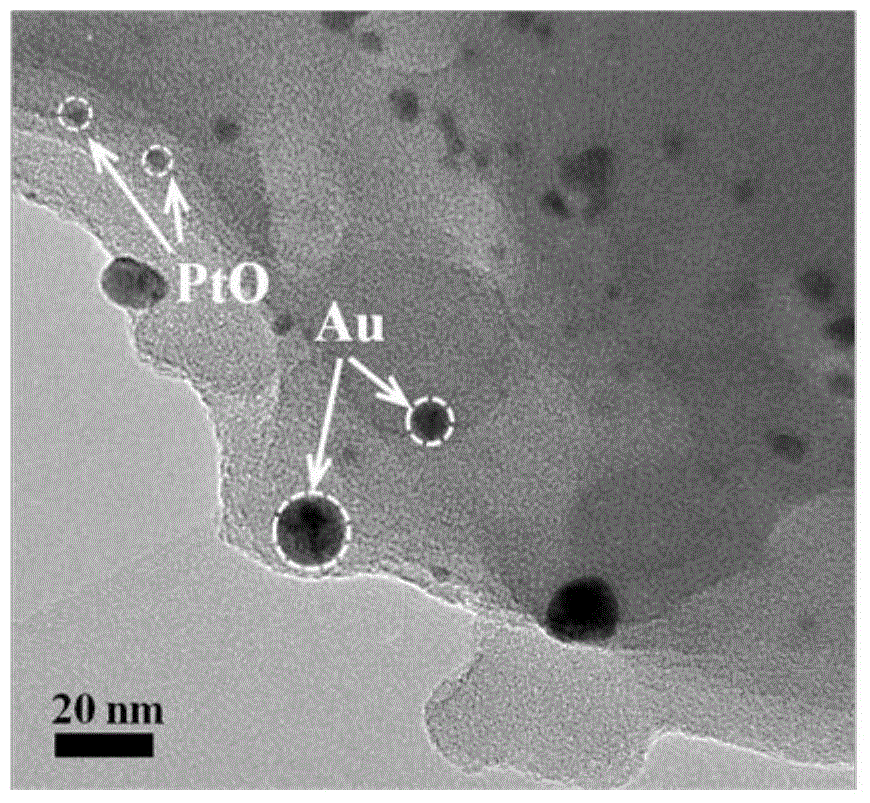

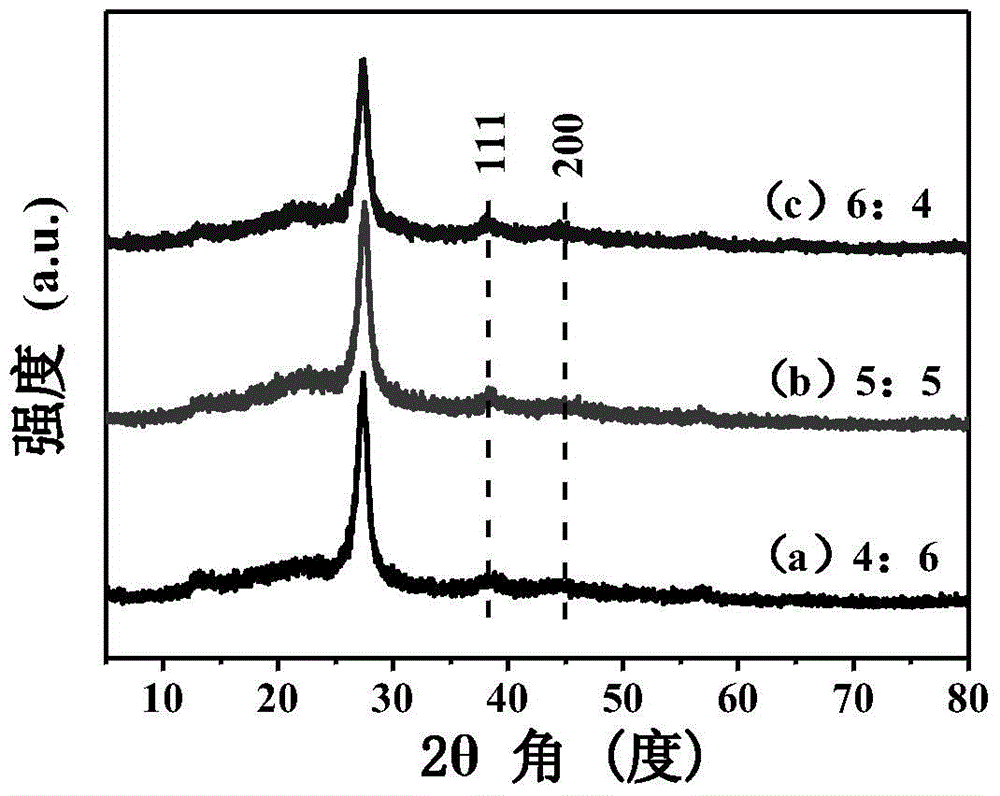

[0033] Take a certain amount of melamine powder and put it in an alumina crucible, cover it and place it in a muffle furnace, heat it to 550°C at a rate of 5°C per minute and keep it at this temperature for 2 hours. When the temperature dropped to room temperature, the obtained light yellow solid was ground into a fine powder which is g-C 3 N 4 . Take 0.1 gram of g-C prepared above 3 N 4The powder was dispersed in a mixed solution of 20 ml of methanol and 60 ml of deionized water by sonication and a certain amount of polyvinylpyrrolidone dispersant was added (in terms of molar ratio, polyvinylpyrrolidone: metal precursor = 10: 1), and stirred under magnetic force Add 0.062 ml of chloroplatinic acid solution (50 mM) and 0.041 ml of chloroauric acid solution (50 mM), the molar ratio of gold and platinum is 4:6, and sonicate for 10 minutes to obtain a uniformly dispersed suspension. The suspension was placed under a 350W xenon lamp for 1 hour of light, and stirring was contin...

Embodiment 2

[0035] Take a certain amount of melamine powder and put it in an alumina crucible, cover it and place it in a muffle furnace, heat it to 550°C at a rate of 5°C per minute and keep it at this temperature for 2 hours. When the temperature dropped to room temperature, the obtained light yellow solid was ground into a fine powder which is g-C 3 N 4 . Take 0.1 gram of g-C prepared above 3 N 4 The powder was dispersed in a mixed solution of 40 ml of methanol and 40 ml of deionized water by sonication and a certain amount of polyvinylpyrrolidone dispersant was added (in terms of molar ratio, polyvinylpyrrolidone: metal precursor = 10: 1), and stirred under magnetic force Add 0.051 ml of chloroplatinic acid solution (50 mM) and 0.051 ml of chloroauric acid solution (50 mM), the molar ratio of gold and platinum is 5:5, and sonicate for 10 minutes to obtain a uniformly dispersed suspension. The suspension was placed under a 350W xenon lamp for 1 hour of light, and stirring was conti...

Embodiment 3

[0037] Take a certain amount of melamine powder and put it in an alumina crucible, cover it and place it in a muffle furnace, heat it to 550°C at a rate of 5°C per minute and keep it at this temperature for 2 hours. When the temperature dropped to room temperature, the obtained light yellow solid was ground into a fine powder which is g-C 3 N 4 . Take 0.1 gram of g-C prepared above 3 N 4 The powder was dispersed in a mixed solution of 35 ml of methanol and 45 ml of deionized water by sonication and a certain amount of polyethylene glycol dispersant was added (by molar ratio, polyethylene glycol: metal precursor = 10: 1). Add 0.041 ml of chloroplatinic acid solution (50 mM) and 0.061 ml of chloroauric acid solution (50 mM) under magnetic stirring, the molar ratio of gold and platinum is 6:4, and sonicate for 10 minutes to obtain a uniformly dispersed suspension. The suspension was placed under a 350W xenon lamp for 1 hour of light, and stirring was continued during the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com