Method for synthesizing indium gallium selenide nanocrystal and film thereof from polyalcohol solution

A nanocrystal and indium selenide technology, applied in the field of indium gallium selenide nanomaterials, can solve the problems of uneven deposition in a large area, difficult control of stoichiometry, restricting application development, etc., and achieves low cost, improved crystallinity, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

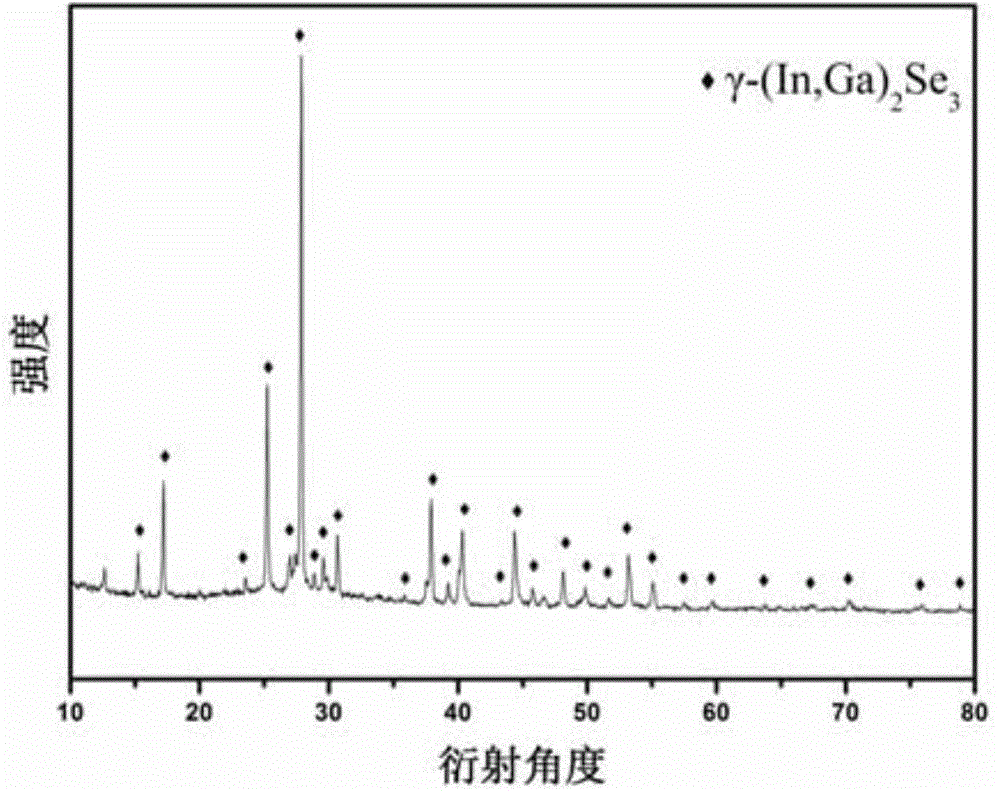

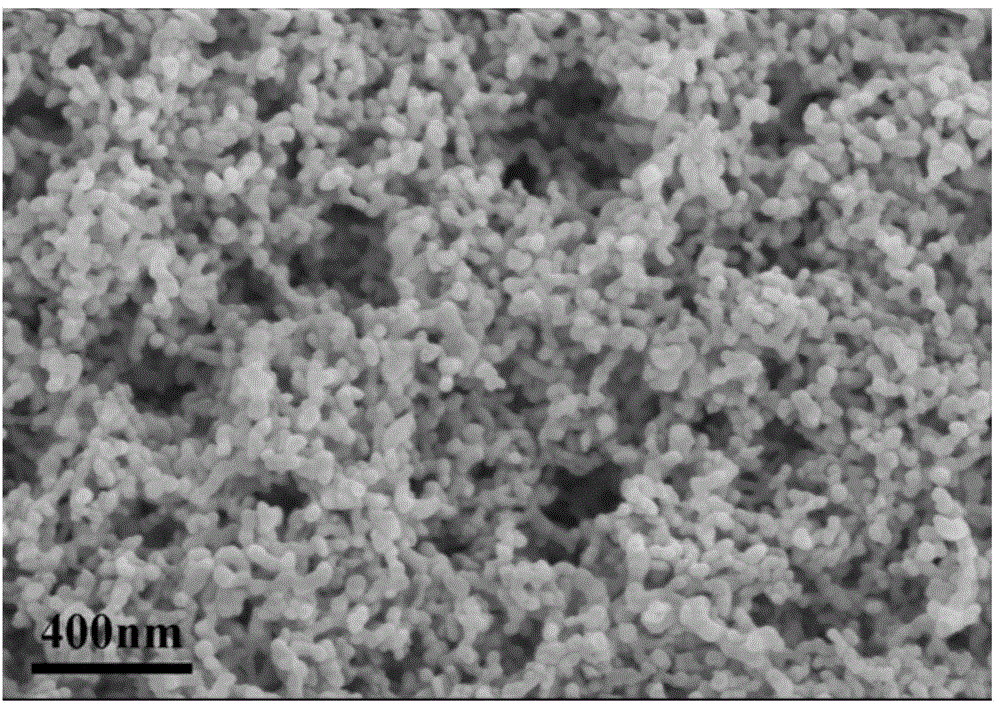

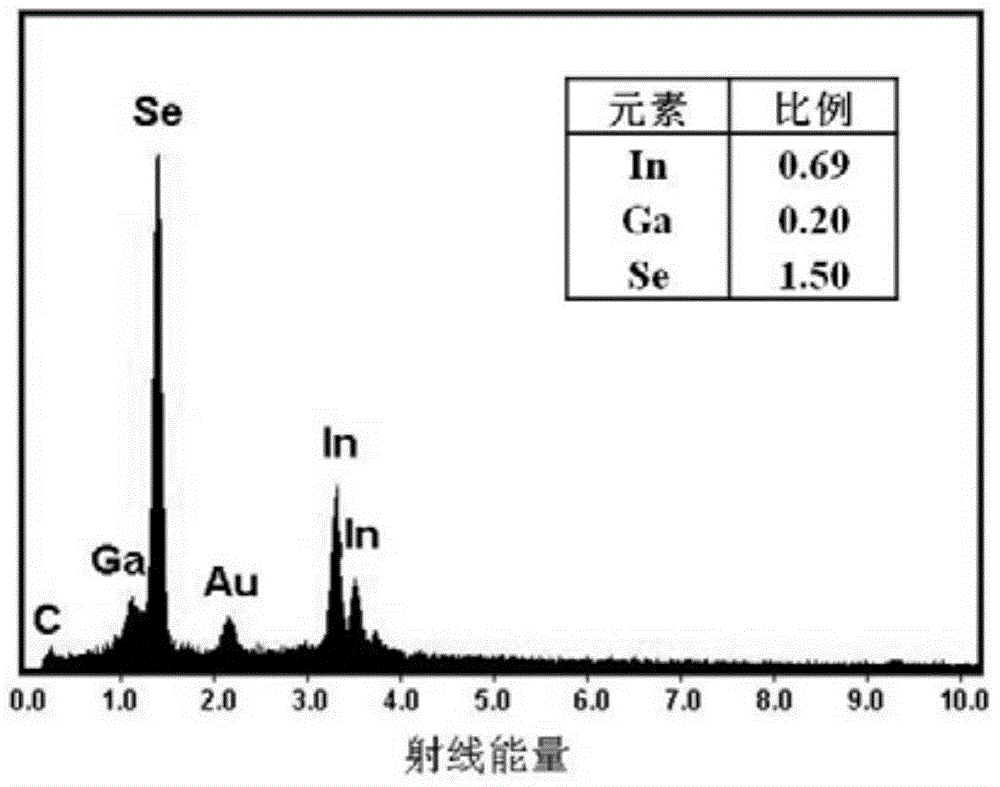

[0037] Examples 1-6 are a series of samples with different addition amounts of ethylenediamine. It can be seen from Table 2 that the main morphology of the product of Example 1 is flake, and the stoichiometric ratio is obviously rich in selenium. The products of Examples 2-6 are granular, and as the addition of ethylenediamine increases, the measured Ga / In molar ratio in the product increases, and the 2θ offset value also increases accordingly. At the same time, as the measured Ga / In molar ratio of the products of Examples 2-5 increases, the measured optical bandgap becomes wider. However, the optical bandgap measured in Example 6 decreases, and one of the reasons may be related to the defect energy level. In terms of the composition of the solution and the In:Ga:Se atomic ratio correspondence of the film sample, the film stoichiometry of Example 5 is closest to the feed ratio of In:Ga:Se=0.70:0.30:1.50 in the reaction solution, thus, Embodiment 5 is the optimum addition amo...

Embodiment 5

[0038] Examples 5 and 7 to 10 are a series of samples with different injection temperature / reflux temperature. It can be concluded from the results in Table 2 that in Example 7, that is, when the injection temperature / reflow temperature is 260 / 240° C., the morphology of the synthesized product is partially flake-like. The stoichiometric ratio of Example 5 is closest to the feed ratio of In:Ga:Se=0.70:0.30:1.50 in the reaction solution. It can be concluded that Example 5 is the optimum injection temperature / reflow temperature, namely 230 / 210°C.

[0039] Examples 5 and 11 to 13 are a series of samples with different addition amounts of dodecanethiol. In Example 11, that is, when the amount of dodecanethiol added is 25 μl, the enrichment of selenium in the stoichiometry is more obvious. In Examples 12, 5, and 13, the molar ratio of Ga / (In+Ga) increases with the increase of dodecanethiol addition. The stoichiometric ratios of Examples 5 and 13 are close to the feed ratio of In:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com