Method for pre-treating organic industrial wastewater based on ferric-carbon micro-electrolysis activated persulfate

A technology for activating persulfate and iron-carbon micro-electrolysis, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of easy stop of reaction and activated persulfate reaction rate Faster and other problems, to achieve the effect of strengthening treatment efficiency, improving removal efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

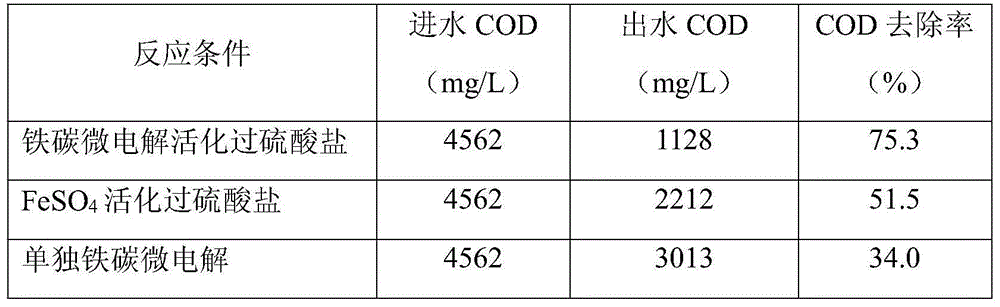

[0030] The industrial wastewater in this example is taken from the drainage of a large chemical enterprise. In order to verify the strengthening of the present invention on the degradation efficiency of refractory pollutants, at the same time only iron-carbon micro-electrolysis was carried out, and Fe 2+ The contrast of activating persulfate, concrete implementation steps are as follows:

[0031] (1) The chemical wastewater mainly contains benzene and caprolactam, and the COD is 4000-5000mg / L. Take 1L of wastewater into the reactor, add iron and carbon with a mass ratio of 1:1, and the amount of iron is 60g. Use HCl to adjust the wastewater The initial pH of the water is 4-5, and aeration is carried out, and the aeration rate is 3-4mg / L;

[0032] (2) add K in the reactor in step (1) 2 S 2 o 8 , to start the persulfate radical oxidation reaction, K 2 S 2 o 8 The dosage is 3mM, and the reaction time is 1.5h;

[0033] (3) pour out the mixed solution that the reaction finis...

Embodiment 2

[0040] The industrial wastewater in this example is taken from the drainage of a chemical plant, mainly containing organic pollutants such as nitrobenzene, nonylphenol polyoxyethylene ether NP10, chloroform, and cyclohexanone, with a COD of 3400-4800 mg / L. Based on the method of iron-carbon micro-electrolysis activation persulfate treatment, the specific steps are as follows:

[0041] (1) Take 500mL of waste water in the reactor, add iron and carbon with a mass ratio of 0.5:1, the amount of iron is 100g, adjust the initial pH of the waste water with HCl to be 5-6, and aerate, the aeration rate is 2-4mg / L;

[0042] (2) add K in the reactor in step (1) 2 S 2 o 8 , to start the persulfate radical oxidation reaction, K 2 S 2 o 8 The dosage is 5mM, and the reaction time is 1h;

[0043] (3) After the reaction is over, pour out the mixed solution in step (2), carry out coagulation precipitation reaction, add Ca(OH) 2 Adjust the pH to 9, then add anionic PAM (dosing amount 2mg...

Embodiment 3

[0046] The industrial wastewater taken in this example is the effluent of a printing and dyeing factory, mainly containing aniline, polyvinyl alcohol and some disperse dyes, and the COD concentration is 5000-8000 mg / L. Using the method of the present invention, the specific implementation steps are as follows:

[0047] (1) Take 500mL of water sample, adjust the initial pH to about 5 with HCl, add iron and carbon with a mass ratio of 3:1, the amount of iron is 50g / L; perform aeration, the aeration rate is 3-5mg / L ;

[0048] (2) In the reactor of step (1), add the Na of 8mM 2 S 2 o 8 , the reaction time is 2.5h;

[0049] (3) After the reaction is over, pour out the mixed solution in step (2), carry out coagulation precipitation reaction, add Ca(OH) 2 Adjust the pH to 10, based on the volume of the mixed solution after the reaction, add anionic PAM (dosing amount 1.5mg / L), stir for 40s, settle for 2 hours, the muddy water is clearly separated, and the supernatant is the post-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com