Preparation method of p-aminophenylethylamine

A technology of p-aminophenethylamine and p-aminophenethyl alcohol, which is applied in the field of preparation of p-aminophenethylamine, can solve the problems of low nitration selectivity, many by-products, increased production costs, etc., and achieves cheap and easy-to-obtain raw materials, High reaction efficiency and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

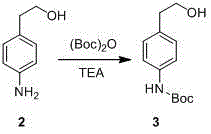

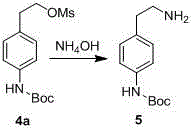

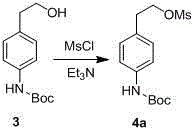

Method used

Image

Examples

Embodiment 1

[0018]

[0019] In a 500mL reaction flask, add 20g of p-nitrophenylethanol (compound 1) and 2g of catalyst palladium carbon into 200mL of methanol, inject hydrogen into the autoclave, the pressure reaches 0.2MPa, and the reaction temperature is 40°C. After 12 hours of reaction, TLC monitors that the reaction of the raw materials is complete, the reaction solution is filtered, and the filtrate is concentrated to obtain 17 g of pure p-aminophenylethanol.

Embodiment 2

[0021]

[0022] In a 500mL reaction flask, add 20g of p-nitrophenylethanol (compound 1) and 2g of catalyst Raney nickel into 200mL of methanol, inject hydrogen into the autoclave, the pressure reaches 0.2MPa, and the reaction temperature is 40°C. After 12 hours of reaction The complete reaction of the raw materials was monitored by TLC, the reaction solution was filtered, and the filtrate was concentrated to obtain 14 g of pure p-aminophenylethanol.

Embodiment 3

[0024]

[0025] In a 500mL reaction flask, add 20g of p-nitrophenylethanol (compound 1) and 1g of catalyst palladium carbon into 200mL of methanol, inject hydrogen into the autoclave, the pressure reaches 0.5MPa, and the reaction temperature is 50°C. After 20 hours of reaction, TLC monitors that the reaction of the raw materials is complete, the reaction solution is filtered, and the filtrate is concentrated to obtain 16.5 g of pure p-aminophenylethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com