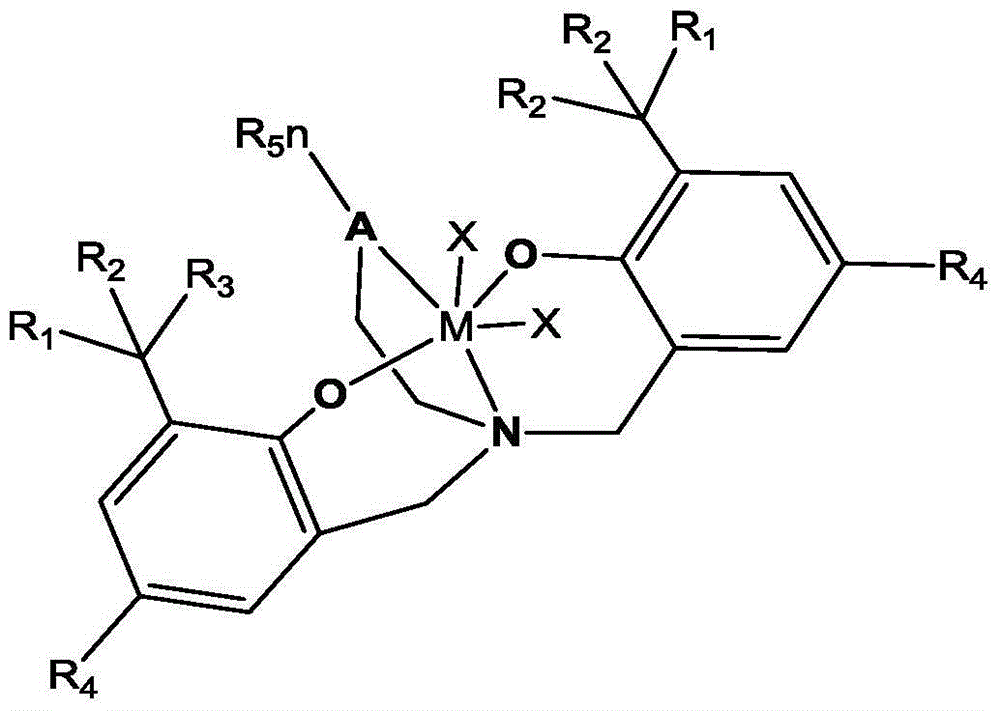

Amine bis phenolate tetradentate ligand IV subgroup metal complex with large special resistance substituent and application thereof

A technology of metal complexes and tetradentate ligands, applied in the field of catalysis, to achieve the effects of long catalytic life, easy availability of raw materials, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

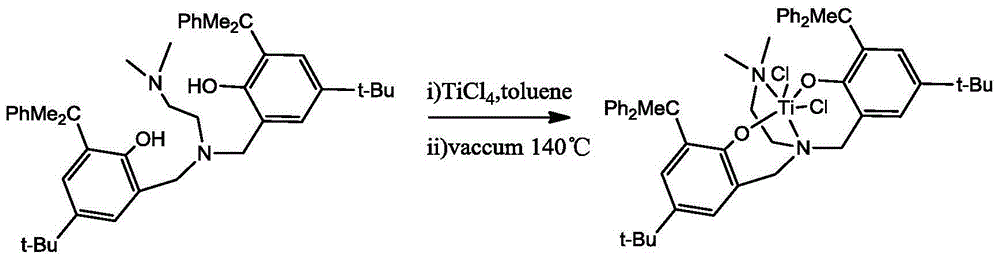

Embodiment 1

[0024]

[0025] At -78°C, first add 216mg (0.33mmol) of bis(2-hydroxy-3-cumyl-5-tert-butyl)benzyl-(N,N-dimethylethylene) to 20ml of toluene Diamine, then add 0.4ml of 0.825M titanium tetrachloride toluene solution, naturally rise to room temperature, stir overnight, drain the solvent, and vacuum at 140°C for 3 hours to obtain 244.9mg of brick-red metal The titanium complex, yield 96.2%, is recorded as complex C1.

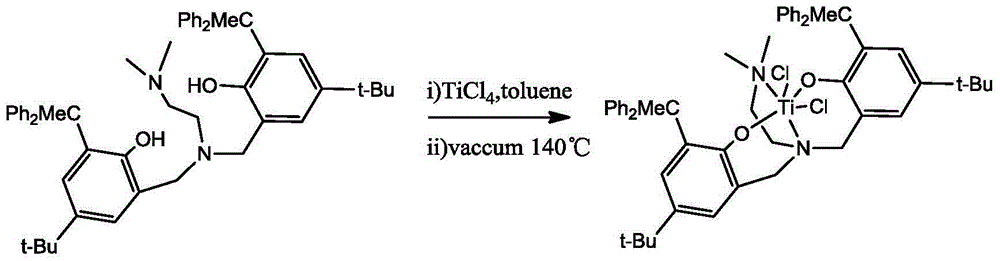

Embodiment 2

[0027]

[0028] At -78°C, first add 258mg (0.33mmol) of bis[2-hydroxy-(2,2-diphenylethyl)-5-tert-butyl]benzyl-(N,N-di Methylethylene) diamine, then add 0.4ml of toluene solution of titanium tetrachloride with a concentration of 0.825M, naturally rise to room temperature, stir overnight, drain the solvent, and vacuum at 140°C for 3h. 283.7 mg of brick-red metal titanium complex can be obtained, with a yield of 95.6%, which is designated as complex C2.

Embodiment 3

[0030]

[0031] At -78°C, first add 299mg (0.33mmol) of bis(2-hydroxy-3-trityl-5-tert-butyl)benzyl-(N,N-dimethylethylene to 20ml of toluene base) diamine, then add 0.4ml of toluene solution of titanium tetrachloride with a concentration of 0.825M, naturally rise to room temperature, stir overnight, drain the solvent, and vacuum at 140°C for 3 hours to obtain 294.3mg brick red The complex of metal titanium, the yield is 87.2%, is recorded as complex C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com