Water-based antistatic coating, its preparation method and application

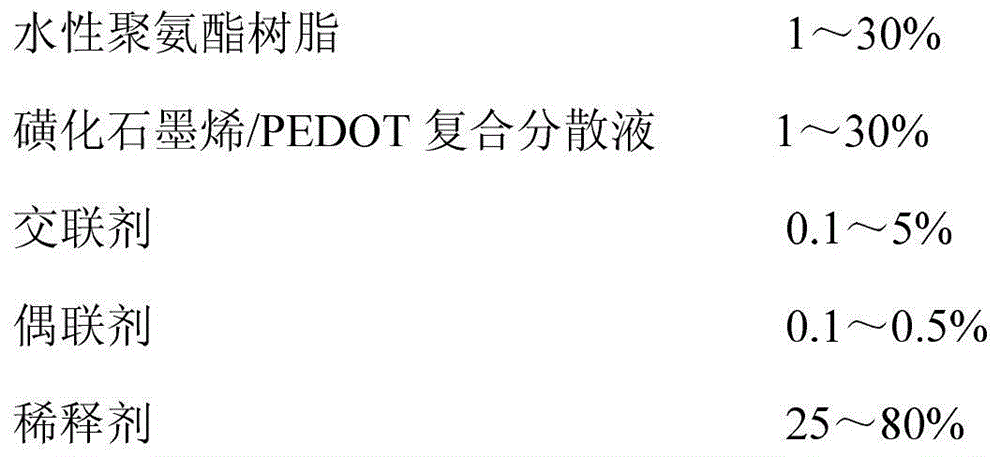

An antistatic and coating technology, used in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of limited, serious conductivity attenuation, and decreased conductivity, and achieve high conductivity, good mechanical properties, and construction. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In a more specific typical embodiment of the present invention, a kind of preparation method of waterborne antistatic coating can comprise the steps:

[0036] (1) Disperse sulfonated graphene, 3,4-ethylenedioxythiophene monomer (EDOT) and polyethylene glycol in deionized water at a temperature of 20-50°C, wherein sulfonated graphene: The mass ratio of EDOT is 0.1:1~1:0.1, the concentration of polyethylene glycol in the system is 0.001~1wt%, the pH value is adjusted to 0.5~4.5, high-speed stirring and mixing, and the rotation speed is 500~1000 rpm;

[0037] (2) While stirring at high speed, slowly add the mixed solution of oxidant and catalyst dropwise, the mass ratio of oxidant to EDOT is 0.5:1~2.5:1, the mass ratio of catalyst to EDOT is 0.001:1~0.1:1, and then Stir for 10-72 hours;

[0038] (3) The product is passed through dialysis or anion-cation exchange resin to remove impurity ions until no impurity ions are obviously detected in the product, and then diluted wi...

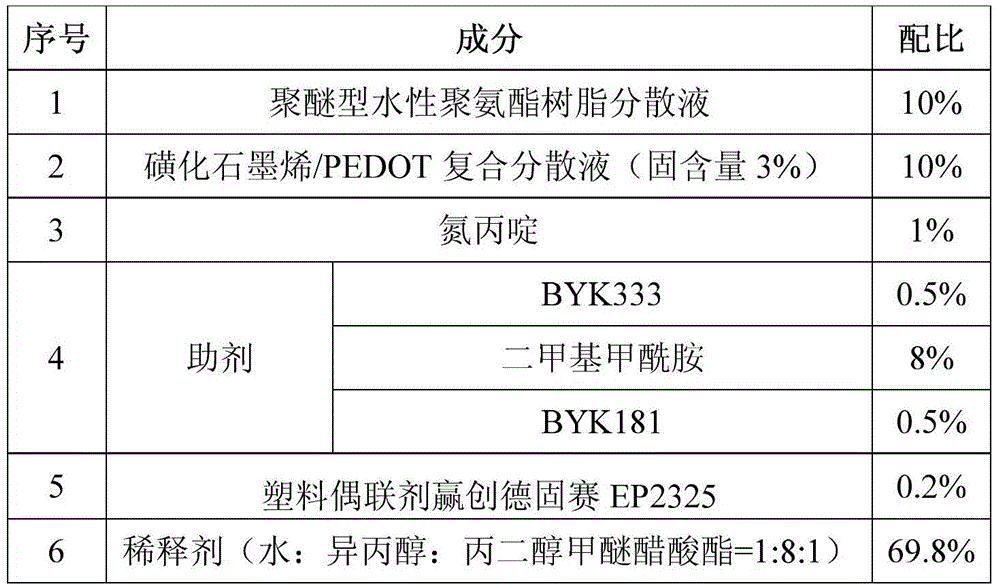

Embodiment 1

[0044] Weigh the raw materials according to the ingredient list, under 40 DEG C of water bath, sulfonated few-layer graphene (self-made with reference to Nano Lett., 2008,.8 (6): 1679-1682), 3,4-ethylenedioxythiophene monomer ( EDOT) and Polyethylene Glycol 400 are dispersed in 500ml deionized water, wherein the mass ratio of sulfonated few-layer graphene: EDOT is 1: 1.2, Polyethylene Glycol 400 concentration is 0.01wt%, its pH value is adjusted with hydrochloric acid to 1.5, stirring for 30 minutes at a speed of 800 rpm. Subsequently, slowly drop the mixed solution of sodium persulfate and ferric sulfate while stirring, the ratio of sodium persulfate to EDOT is 1:1, the mass ratio of ferric sulfate to EDOT is 0.01:1, and stir for 24 hours after the addition. The product was passed through a dialysis bag to remove impurity ions, and then diluted with deionized water to adjust the solid content of the solution to 3 wt%, to obtain a sulfonated graphene / PEDOT composite dispersion...

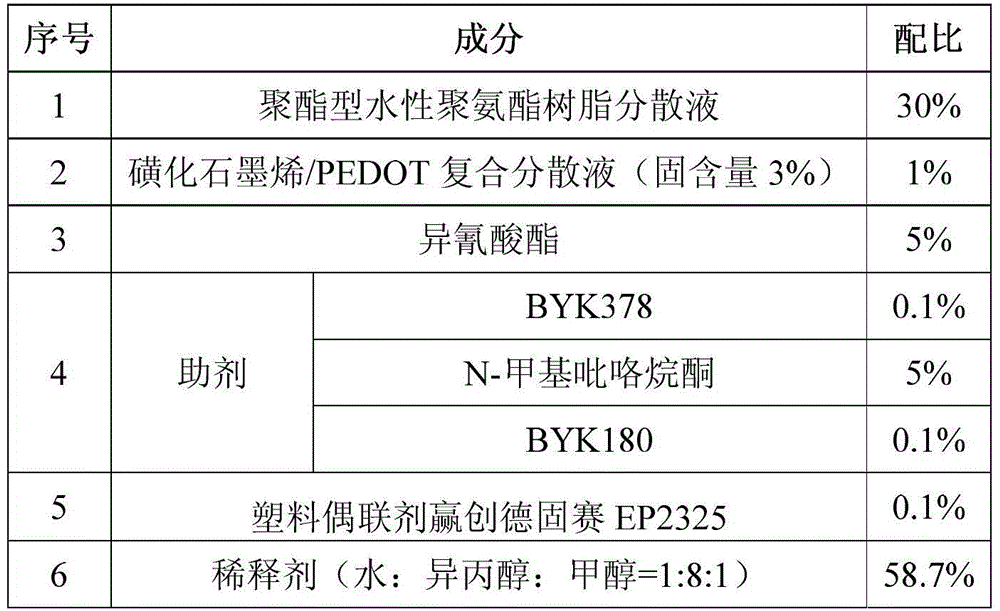

Embodiment 2

[0047] Embodiment 2: The difference between this embodiment and Example 1 is that the coating formula is different, and the coating formula is as follows (wt%):

[0048]

[0049] Referring to the scheme of Example 1, the antistatic PET material obtained by using the coating of this example has a light transmittance of 98% and a surface resistance of 10e9 ohms / square.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com