Making method of surface double-walled hollow turbine blade

A technology for turbine blades and a manufacturing method, applied in the field of rapid casting, can solve the problems of difficulty in meeting new blade manufacturing requirements, difficulty in realizing hollow blade manufacturing, poor temperature bearing capacity of blades, etc., and achieves simple mold, high forming accuracy, and hole structure defects. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for manufacturing double-walled hollow turbine blades, comprising the following steps:

[0049] 1) Manufacture of resin negatives for double-walled hollow turbine blades

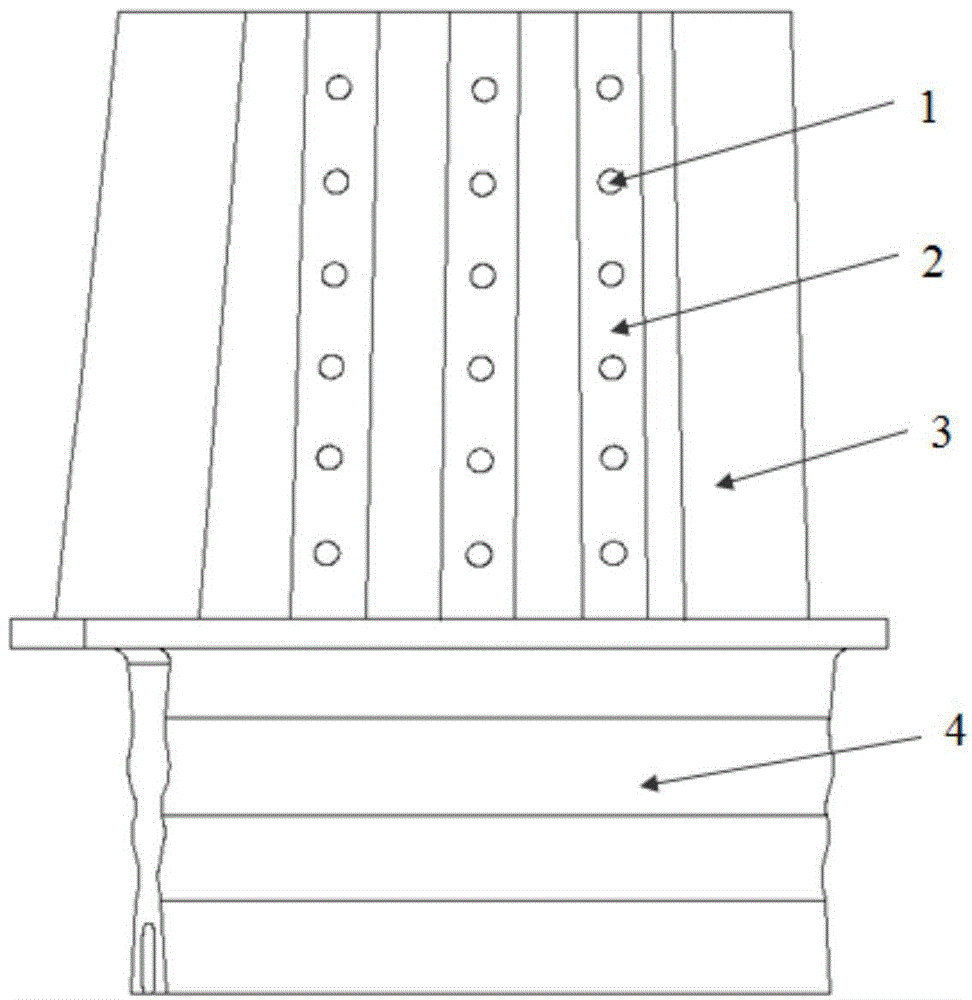

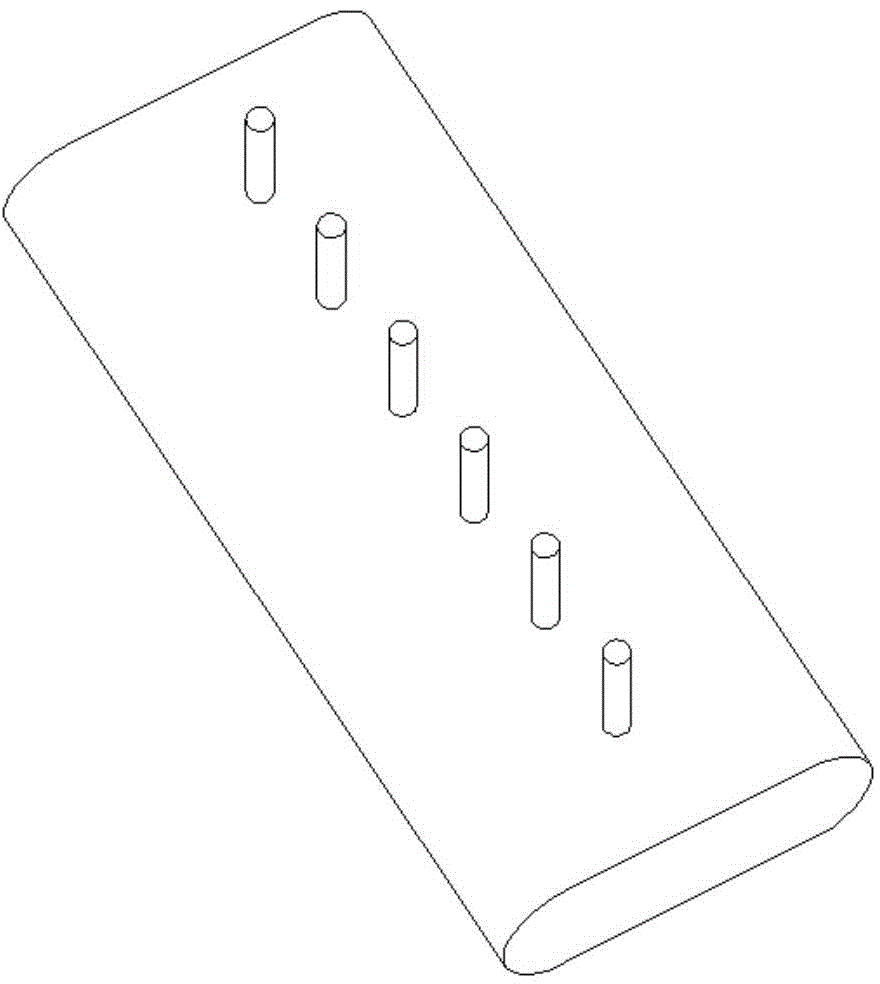

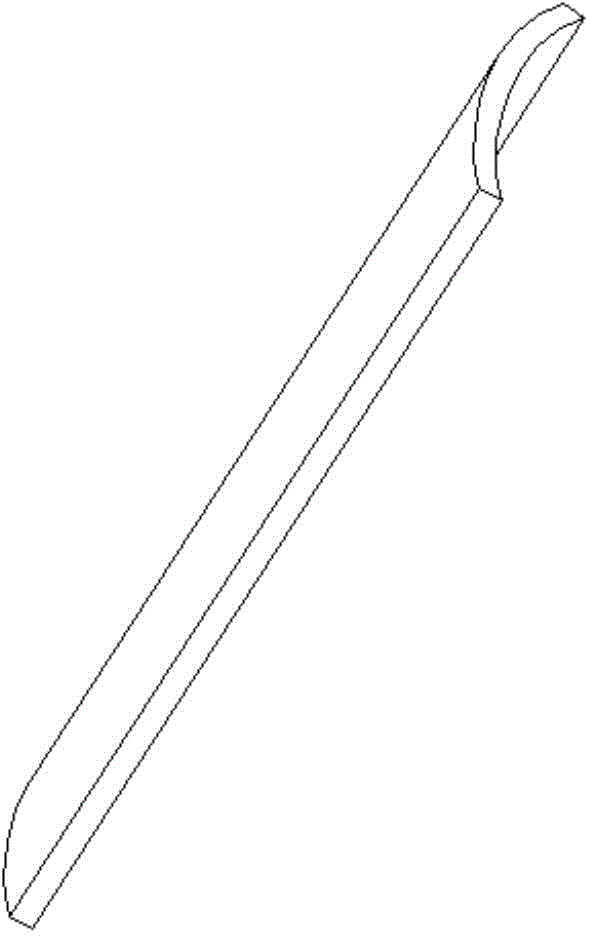

[0050] see figure 1 , the figure shows the resin prototype part of the double-walled hollow turbine blade with tenons, in the figure, 1 is the impact hole, 2 is the double-walled cooling channel, 3 is the airfoil, and 4 is the tenon. see image 3 , which shows the outer walls of the resin mated to the resin prototype.

[0051] First, the resin negative model of the double-walled hollow turbine blade is designed based on 3D software. The negative model consists of the resin prototype containing the impingement hole, the resin outer wall corresponding to the double-walled cooling channel, and the resin shell. The negative model is discretized by layering software to generate two-dimensional slices, and the specific data of each layer of the model is obtained, and then the data is imported in...

Embodiment 2

[0075] A method for manufacturing double-walled hollow turbine blades, comprising the following steps:

[0076] 1) Manufacture of resin negatives for double-walled hollow turbine blades

[0077] First, the resin negative model of the double-walled hollow turbine blade is designed based on 3D software. The negative model consists of the resin prototype containing the impingement hole, the resin outer wall corresponding to the double-walled cooling channel, and the resin shell. The negative model is discretized by layering software to generate two-dimensional slices, and the specific data of each layer of the model is obtained, and then the data is imported into the photocuring molding machine in STL format, and the photosensitive resin is cured and molded by laser irradiation, and manufactured separately. Resin negatives for individual parts of double walled hollow turbine blades. After the manufacture is completed, use alcohol to remove excess liquid resin on the surface, and...

Embodiment 3

[0096] A method for manufacturing double-walled hollow turbine blades, comprising the following steps:

[0097] 1) Manufacture of resin negatives for double-walled hollow turbine blades

[0098] Firstly, the resin negative shape of the double-walled hollow turbine blade is designed based on 3D software. The negative shape is composed of the resin prototype including the impingement hole, the resin outer wall corresponding to the double-walled cooling channel, and the resin shell. The negative model is discretized by layering software to generate two-dimensional slices, and the specific data of each layer of the model is obtained, and then the data is imported into the photocuring molding machine in STL format, and the photosensitive resin is cured and molded by laser irradiation, and manufactured separately. Resin negatives for individual parts of double walled hollow turbine blades. After the manufacture is completed, use alcohol to remove excess liquid resin on the surface,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com