Lithium metaborate hydrogen storage composite material adulterated with lithium hydride and preparation method thereof

A technology of composite materials and lithium metaborate, which is applied in the field of hydrogen storage composite materials and its preparation, can solve the problems of slow hydrogen discharge rate and high hydrogen discharge temperature, and achieve the effects of fast hydrogen discharge rate, low hydrogen discharge temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Under the protection of argon atmosphere, LiH and LiBO 2 Place it in the ball mill tank of a high-energy ball mill at a molar ratio of 1:1 for ball milling, the ball-to-material ratio is 40:1, the ball material is stainless steel, the rotating speed is 500r / min, the ball milling time is 1h, and the ball milling method is positive / Reverse intermittent ball milling, every 15 minutes of ball milling, and 15 minutes of intermittent ball milling. After the ball milling is completed, it is naturally cooled to room temperature, and then compressed into tablets and packaged in an argon atmosphere.

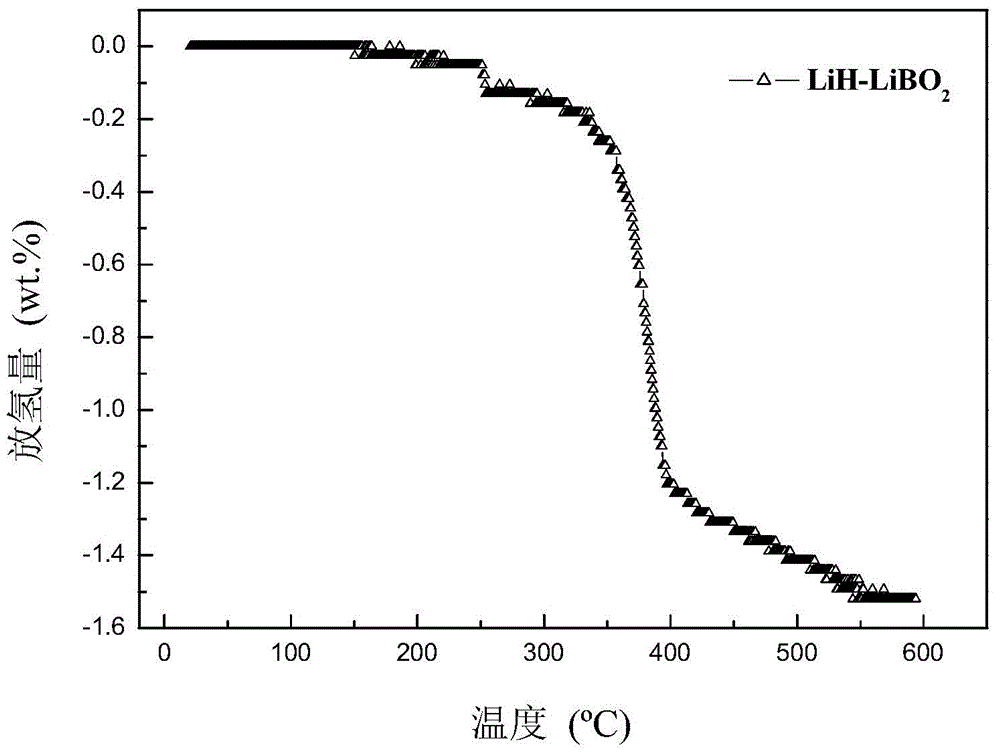

[0020] Take a small amount of compressed samples and put them into the sample tube for temperature programmed desorption (TPD) test. The heating conditions are as follows: the heating rate is 5°C / min, the temperature rise range is from room temperature to 600°C, and the holding temperature is 600°C. Such as figure 1 As shown, it can be seen that the doped LiBO 2 The hydrogen rele...

Embodiment 2

[0022] Under the protection of argon atmosphere, LiH and LiBO 2 Place it in the ball mill tank of a high-energy ball mill at a molar ratio of 1:1 for ball milling, the ball-to-material ratio is 10:1, the ball material is stainless steel, the speed is 200r / min, the ball milling time is 5h, and the ball milling method is positive / Reverse intermittent ball milling, every 15 minutes of ball milling, and 15 minutes of intermittent ball milling. After the ball milling is completed, it is naturally cooled to room temperature, and then compressed into tablets and packaged in an argon atmosphere.

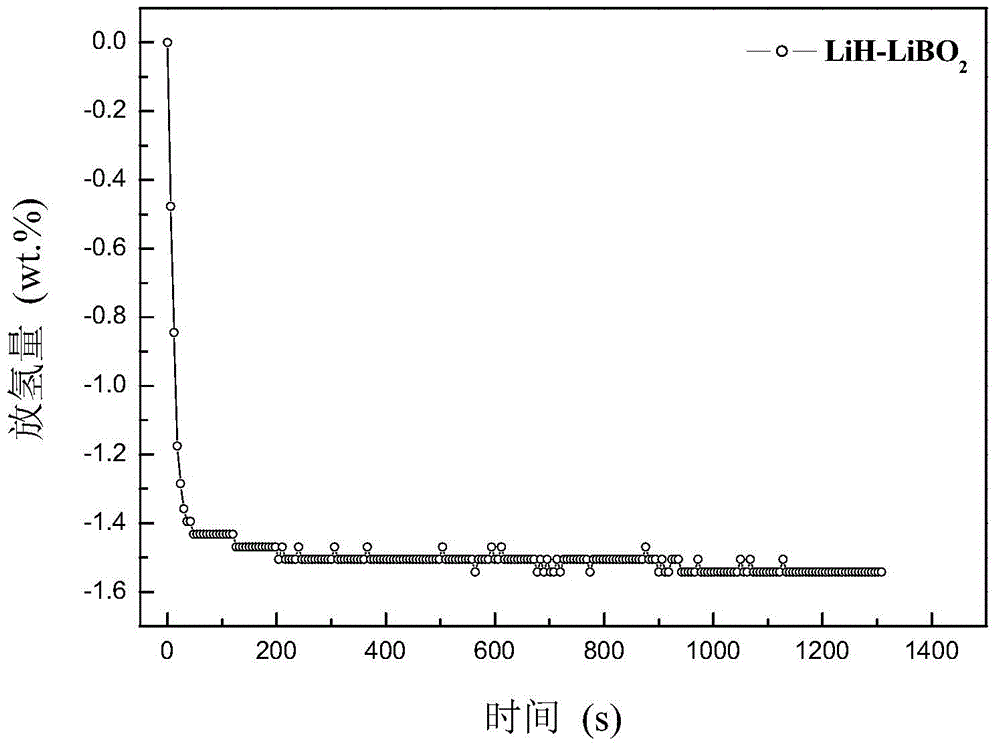

[0023] Take a small amount of compressed sample and put it into the sample tube for hydrogen desorption kinetics test. A hydrogen pressure of 3.0 MPa was given when the temperature was raised to prevent the sample from releasing hydrogen before 450°C. Such as figure 2 As shown, it can be seen that the doped LiBO at 450 °C 2 The hydrogen desorption rate of the composite material is very ...

Embodiment 3

[0025] Under the protection of argon atmosphere, LiH and LiBO 2 Place it in the ball mill tank of a high-energy ball mill at a molar ratio of 2:1 for ball milling, the ball-to-material ratio is 30:1, the ball material is stainless steel, the speed is 300r / min, the ball milling time is 5h, and the ball milling method is positive / Reverse intermittent ball milling, every 15 minutes of ball milling, and 15 minutes of intermittent ball milling. After the ball milling is completed, it is naturally cooled to room temperature, and then compressed into tablets and packaged in an argon atmosphere.

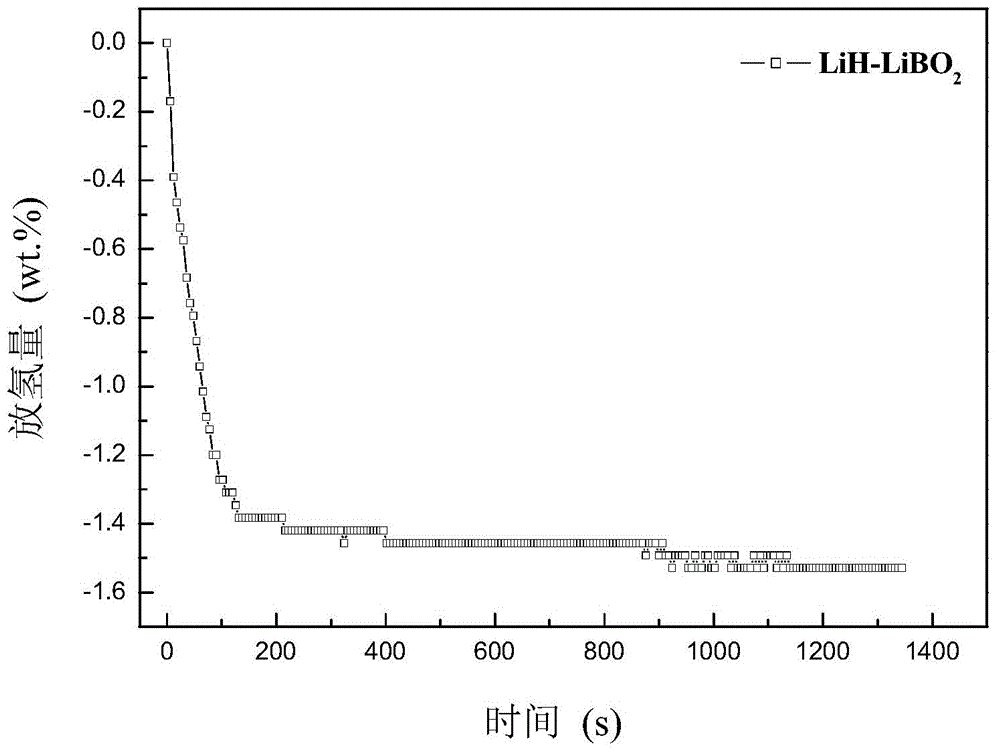

[0026] Take a small amount of compressed sample and put it into the sample tube for hydrogen desorption kinetics test. When the temperature is raised, a hydrogen pressure of 3.0 MPa is given to suppress the hydrogen release of the sample before 500°C. From the results of hydrogen desorption, at 500°C, the hydrogen desorption rate of the hydrogen storage material is equivalent to that of Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com