Composite cement grinding aid

A compound cement and grinding aid technology, which is applied in the field of compound cement grinding aids, can solve the problems of cement and concrete durability safety hazards, unstable grinding aid quality, and cement quality fluctuations, so as to increase the scope of use and improve the quality of cement. The effect of improving the output per hour and the effect of grinding aid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

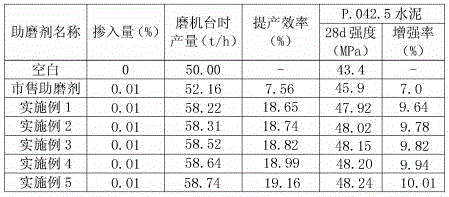

Examples

Embodiment 1

[0009] A composite cement grinding aid, consisting of the following components in parts by weight: 10 parts by weight of triethanolamine, 4 parts of sodium formate, 4 parts of sodium acetate, 10 parts of sodium chloride, 8 parts of urea, 15 parts of compound alcohol mother liquor, 2 parts of ammonium sulfate, and 10 parts of sodium thiosulfate , calcium lignosulfonate 2, diethylene glycol 4, sodium lignosulfonate 3, molasses 10, fly ash 10, mix and stir the above raw materials for 30 minutes to obtain the product of the present invention.

Embodiment 2

[0011] A composite cement grinding aid, consisting of the following components in parts by weight: 15 parts by weight of triethanolamine, 1 sodium formate, 1 sodium acetate, 6 sodium chloride, 5 urea, 10 compound alcohol mother liquor, 1 ammonium sulfate, and 5 sodium thiosulfate , calcium lignosulfonate 1, diethylene glycol 1, sodium lignosulfonate 1, molasses 6, fly ash 6, mix and stir the above raw materials for 30 minutes to obtain the product of the present invention.

Embodiment 3

[0013] A composite cement grinding aid, consisting of the following components in parts by weight: 12 triethanolamine, 3 sodium formate, 3 sodium acetate, 9 sodium chloride, 7 urea, 14 compound alcohol mother liquor, 1.6 ammonium sulfate, and 8 sodium thiosulfate , calcium lignosulfonate 1.6, diethylene glycol 3, sodium lignosulfonate 2.5, molasses 9, fly ash 9, mix and stir the above raw materials for 30 minutes to obtain the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com