Composite mineral admixture for concrete

A technology of composite minerals and admixtures, applied in the field of composite mineral admixtures for concrete, can solve the problems of consuming a large amount of coal, water, electricity and mine resources, the unsustainable development of the concrete industry, and the shortage of resources. Significant economic benefits, reduction of concrete cracks, and improvement of engineering utilization functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

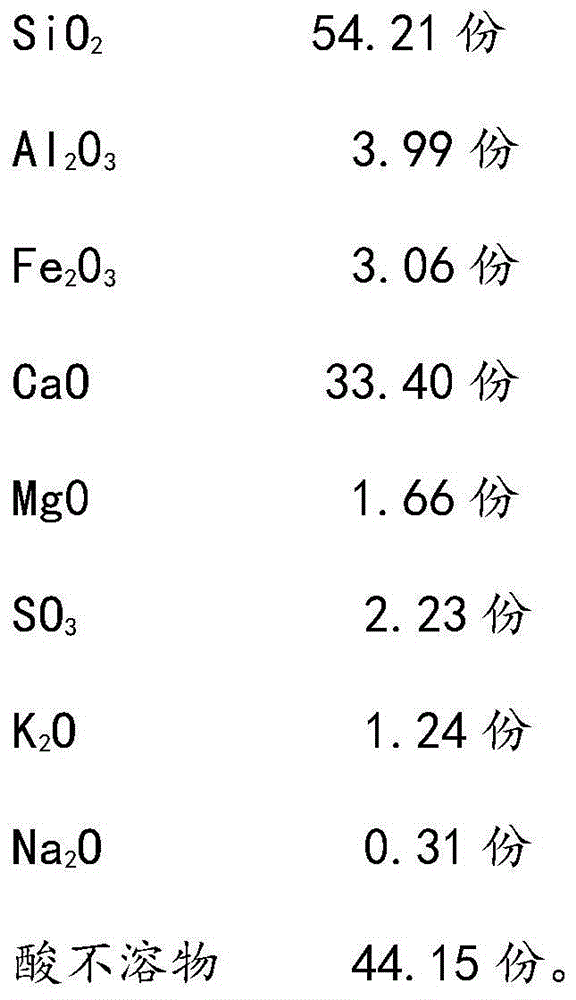

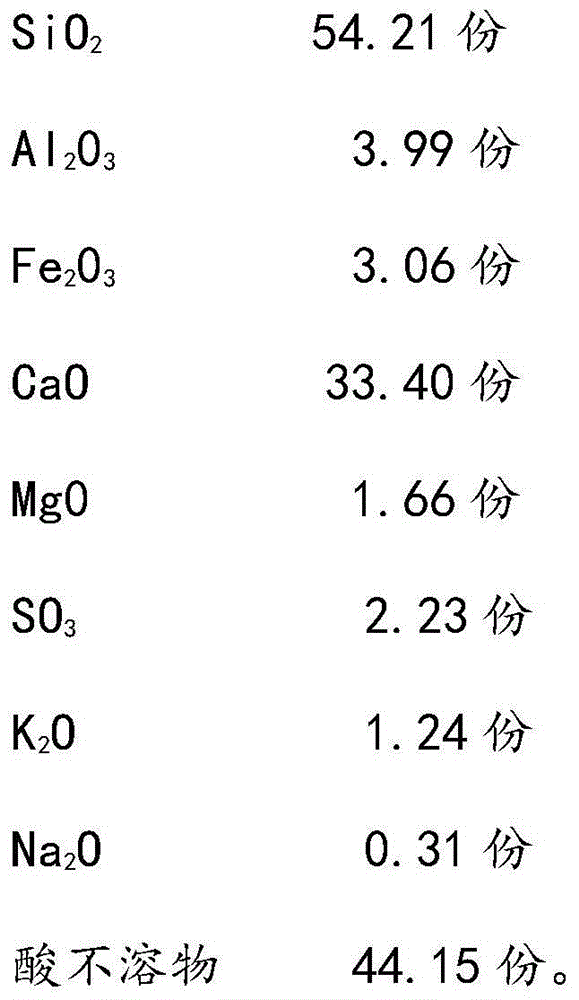

[0014] Composite mineral admixtures for concrete include cement clinker, limestone powder, fly ash, mineral powder and silica fume. Cement clinker, limestone powder, fly ash, mineral powder and silica fume respectively account for The weight percentage of the total weight is: cement clinker is 15%-20%, mineral powder is 30%-40%, silica fume is 8%-15%, limestone powder is 20%-30%, and fly ash is 15%. —25%, of which, limestone powder is processed from mining debris.

[0015] In this embodiment, silica fume contains SiO 2 ≧82% lower quality silica fume, the mineral powder is ground from granulated blast furnace slag. The composite mineral admixture for concrete is made by crushing, grinding and mixing cement clinker, mineral powder, silica fume, limestone powder and fly ash.

[0016] The preferred raw material weight percentages of composite mineral admixtures for concrete are: cement clinker accounts for 20% of the total weight of the admixture; mineral powder accounts for 35%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com