Organic fertilizer containing wormcast and rice bran and preparation method thereof

A technology of vermicompost and rice bran husks is applied in the preparation of organic fertilizers, organic fertilizers, bio-organic part treatment and other directions, which can solve the problems of high cost, little difference, and only 15%, and achieves fertilizer efficiency improvement and seedling emergence rate. The effect of improving and reducing planting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

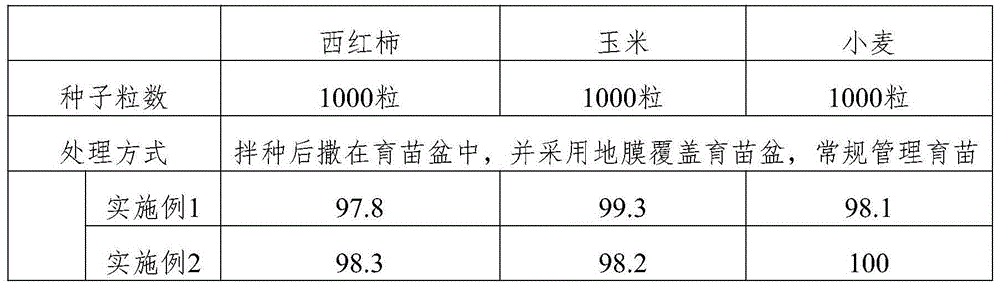

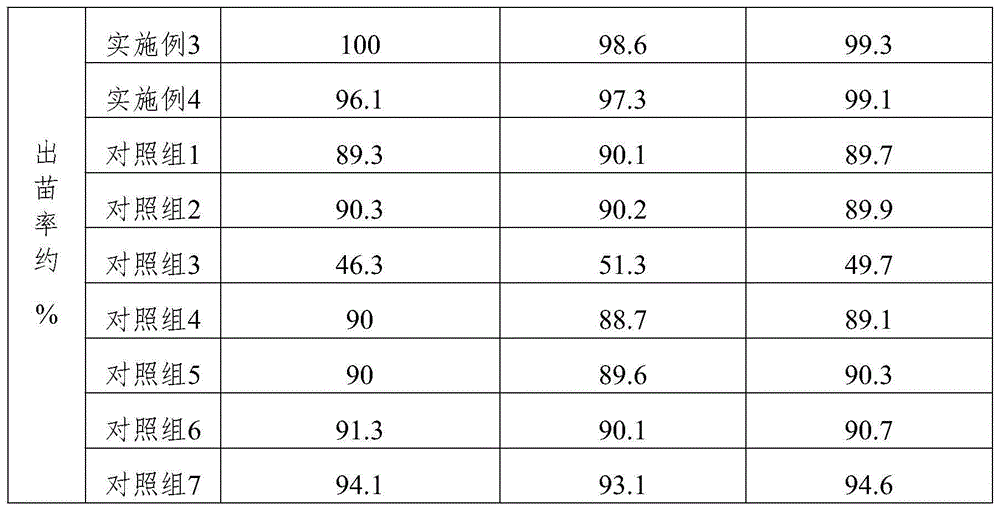

Examples

Embodiment 1

[0024] An organic fertilizer containing vermicompost and rice bran husks. The raw material components are 20 kg of vermicompost, 18 kg of cow dung, 13 kg of oily rot, 13 kg of rice bran husks and 3 kg of starter.

[0025] The fermentation agent, its raw material composition formula by weight is 3kg of Saccharomyces cerevisiae, 1kg of Lactobacillus plantarum, 2kg of Enterococcus faecalis, 0.1kg of protease, 7kg of corn gluten powder, 1kg of whey powder, and 2kg of lactose. The preparation method is to add Saccharomyces cerevisiae, Lactobacillus plantarum, Enterococcus faecalis, protease, corn gluten powder, whey powder, and lactose into a stirring mixing tank in sequence according to the ratio, and stir and mix at a stirring speed of 20r / min. And during the stirring and mixing process, control the temperature in the stirrer to maintain at 20°C, and after the stirring is completed, adjust the temperature to maintain at 18°C and let stand for 3 minutes.

[0026] Vermicompost is...

Embodiment 2

[0032] An organic fertilizer containing vermicompost and rice bran husks. The raw material components are 30 kg of vermicompost, 25 kg of cow dung, 19 kg of oil rot, 15 kg of rice bran husks and 5 kg of starter.

[0033]Described leavening agent, its raw material composition by weight formula is 7kg of Saccharomyces cerevisiae, 5kg of Lactobacillus plantarum, 6kg of Enterococcus faecalis, 0.5kg of protease, 9kg of corn gluten powder, 4kg of whey powder, 5kg of lactose. The preparation method is to add Saccharomyces cerevisiae, Lactobacillus plantarum, Enterococcus faecalis, protease, corn gluten powder, whey powder, and lactose into a stirring mixing tank in sequence according to the ratio, and stir and mix at a stirring speed of 40r / min. And during the stirring and mixing process, control the temperature in the stirrer to maintain at 34°C, and after the stirring is completed, adjust the temperature to maintain at 27°C and let it stand for 5 minutes.

[0034] The vermicompost ...

Embodiment 3

[0040] An organic fertilizer containing vermicompost and rice bran husks, the raw material components are 25kg of vermicompost, 23kg of cow dung, 17kg of oily rot, 14kg of rice bran husks and 4kg of starter.

[0041] Described leavening agent, its raw material composition by weight formula is Saccharomyces cerevisiae 5kg, Lactobacillus plantarum 3kg, Enterococcus faecalis 4kg, protease 0.3kg, corn gluten powder 8kg, whey powder 2kg, lactose 4kg. The preparation method is to add Saccharomyces cerevisiae, Lactobacillus plantarum, Enterococcus faecalis, protease, corn gluten powder, whey powder, and lactose into a stirring mixing tank in sequence according to the ratio, and stir and mix at a stirring speed of 30r / min. And during the stirring and mixing process, control the temperature in the stirrer to maintain at 27°C, and after the stirring is completed, adjust the temperature to maintain at 25°C and let stand for 4 minutes.

[0042] The vermicompost is obtained by using yellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com