Application of a Hierarchical Ti-ZSM-5 Molecular Sieve Catalyst in the Synthesis of Toluene and Xylene

A molecular sieve and multi-level pore technology, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of affecting the diffusion performance of pores, reducing the utilization rate of methanol, affecting the crystallinity of molecular sieves, etc., and achieving high utilization rate of methanol , the effect of reducing cost and energy consumption, low ethylbenzene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

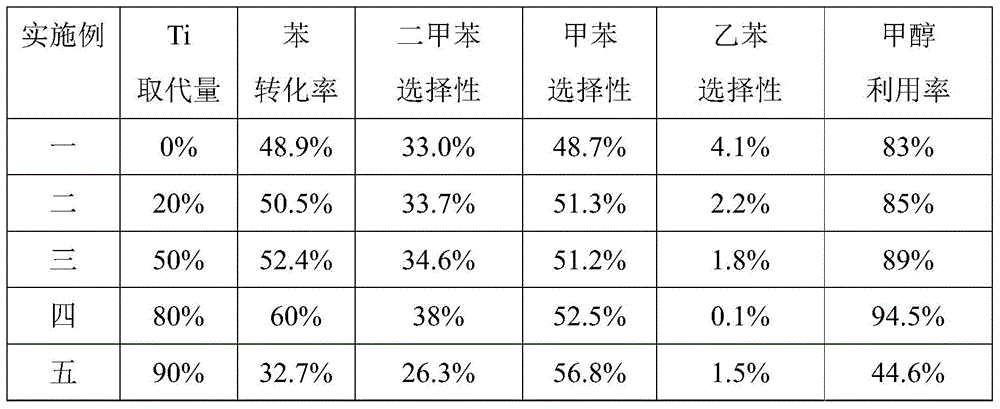

Embodiment 1

[0026] Embodiment one: with 0.068g aluminum isopropoxide, 10g tetrapropyl ammonium hydroxide aqueous solution (25wt%), 13.2ml tetraethyl orthosilicate, 1.21g hexadecyltrimethoxysilane (85wt%) and 52ml ethanol Mix in a beaker and stir at 20°C until a gel is formed; the gel is dried at 20°C for 24 hours, then the gel is transferred to a PTFE liner (A) with a volume of 50ml, and another 250ml Add 40ml of deionized water to the polytetrafluoroethylene lining (B), then transfer the above-mentioned lining (A) to the lining (B), and now the deionized water is between the two linings; Transfer the good lining to a 250ml stainless steel hydrothermal kettle, crystallize at 170°C for 70h; filter and wash, dry at 100°C for 4h, and roast at 550°C for 10h; Sieve, take the catalyst with particle size of 20-40 meshes, and then prepare the hierarchical porous Ti-ZSM-5 molecular sieve with 0 mol% Ti substitution.

Embodiment 2

[0027] Example 2: 0.0544g aluminum isopropoxide, 0.0151g tetraethyl titanate, 10g tetrapropylammonium hydroxide aqueous solution (25wt%), 13.2ml tetraethyl orthosilicate, 1.21g hexadecyltrimethoxy Silane (85wt%) and 52ml ethanol were mixed in a beaker and stirred at 20°C until a gel was formed; the gel was dried at 20°C for 24h, and then the gel was transferred to a PTFE liner with a volume of 50ml (A) , take another polytetrafluoroethylene liner (B) with a volume of 250ml and add 40ml of deionized water to it, then transfer the above-mentioned liner (A) to the liner (B), at this time the deionized water is located Between the two inner linings; transfer the assembled inner lining to a 250ml stainless steel hydrothermal kettle, and crystallize at 170°C for 70h; after filtering and washing, dry at 100°C for 4h, and roast at 550°C for 10h; The catalyst is pressed into tablets, crushed and sieved, and the catalyst with a particle size of 20-40 meshes is taken to obtain a hierarch...

Embodiment 3

[0028] Example three: 0.034g aluminum isopropoxide, 0.0378g tetraethyl titanate, 10g tetrapropyl ammonium hydroxide aqueous solution (25wt%), 13.2ml tetraethyl orthosilicate, 1.21g hexadecyltrimethoxy Silane (85wt%) and 52ml ethanol were mixed in a beaker and stirred at 20°C until a gel was formed; the gel was dried at 20°C for 24h, and then the gel was transferred to a PTFE liner with a volume of 50ml (A) , take another polytetrafluoroethylene liner (B) with a volume of 250ml and add 40ml of deionized water to it, then transfer the above-mentioned liner (A) to the liner (B), at this time the deionized water is located Between the two inner linings; transfer the assembled inner lining to a 250ml stainless steel hydrothermal kettle, and crystallize at 170°C for 70h; after filtering and washing, dry at 100°C for 4h, and roast at 550°C for 10h; The catalyst is pressed into tablets, crushed and sieved, and the catalyst with a particle size of 20 to 40 meshes is taken to obtain a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com