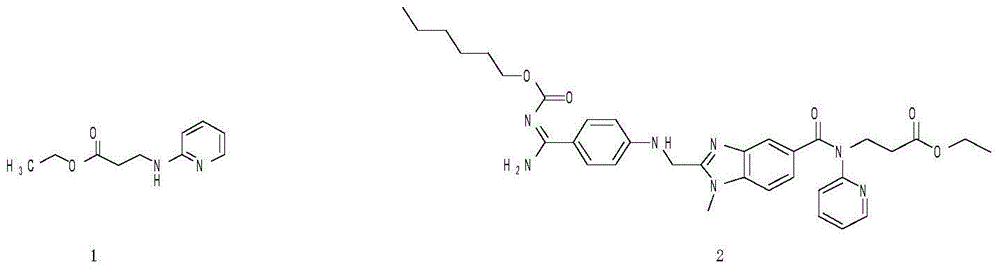

Ethyl 3-(pyridin-2-ylamino)propanoate post-treatment purification method

A technology of ethyl propionate and purification method, which is applied in the field of compound purification and post-processing and purification of 3-ethyl propionate, can solve the problems of complicated post-processing process, low yield, unenvironmental protection, etc., and achieve technological progress Significant, improved purity, low production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

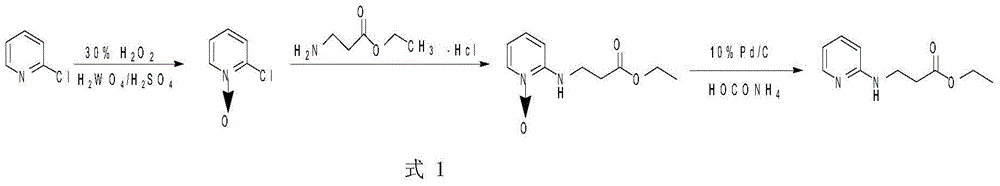

Problems solved by technology

Method used

Image

Examples

Embodiment 1

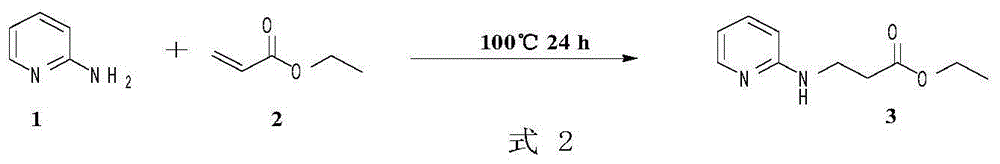

[0028] This example dabigatran etexilate synthetic process intermediate 3-(pyridin-2-yl amino) ethyl propionate is synthetic, and described synthetic reaction equation is as follows:

[0029]

[0030] The synthetic concrete steps of above-mentioned reaction and aftertreatment purification method are as follows:

[0031] (1) Take a 500mL round-bottomed flask, put it into an electromagnetic stirrer of appropriate size, weigh 50g of o-aminopyridine into the bottle, and add 28.3mL of absolute ethanol;

[0032] (2) Stir for 20 minutes, and when the solid is dissolved or mostly dissolved, add 56.5 mL of ethyl acrylate to step (1);

[0033] (3) Stir for 10min, slowly add 4.8mL trifluoromethanesulfonic acid dropwise;

[0034] (4) Add nitrogen protection, stir and reflux in an oil bath at 120-160°C for 16-20 hours;

[0035] (5) After the reaction is completed, the reaction solution is washed with recovered petroleum ether or ethyl acetate for 2 to 3 times at a temperature of 35-40...

Embodiment 2

[0041] This example dabigatran etexilate synthetic process intermediate 3-(pyridin-2-yl amino) ethyl propionate is synthetic, and described synthetic reaction equation is as follows:

[0042]

[0043] The synthetic concrete steps of above-mentioned reaction and aftertreatment purification method are as follows:

[0044] (1) Take a 500mL round-bottomed flask, put it into an electromagnetic stirrer of appropriate size, weigh 100g of o-aminopyridine into the bottle, and add 56.6mL of absolute ethanol;

[0045] (2) Stir for 20 minutes, and when the solid is dissolved or most of it is dissolved, add 113 mL of ethyl acrylate to step (1);

[0046] (3) Stir for 10 min, slowly add 9.6 mL of trifluoromethanesulfonic acid dropwise;

[0047] (4) Add nitrogen protection, stir and reflux in an oil bath at 120-160°C for 16-20 hours;

[0048] (5) After the reaction is completed, the reaction solution is washed with recovered petroleum ether or ethyl acetate for 2 to 3 times at a temperat...

Embodiment 3

[0054] This example dabigatran etexilate synthetic process intermediate 3-(pyridin-2-yl amino) ethyl propionate is synthetic, and described synthetic reaction equation is as follows:

[0055]

[0056] The synthetic concrete steps of above-mentioned reaction and aftertreatment purification method are as follows:

[0057] (1) Take a 500mL round-bottomed flask, put it into an electromagnetic stirrer of appropriate size, weigh 150g of o-aminopyridine into the bottle, and add 84.9mL of absolute ethanol;

[0058] (2) Stir for 20 minutes, and when the solid is dissolved or mostly dissolved, add 169.5 mL of ethyl acrylate to step (1);

[0059] (3) Stir for 10 min, slowly add 14.4 mL of trifluoromethanesulfonic acid dropwise;

[0060](4) Add nitrogen protection, stir and reflux in an oil bath at 120-160°C for 16-20 hours;

[0061] (5) After the reaction is completed, the reaction solution is washed with recovered petroleum ether or ethyl acetate for 2 to 3 times at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com