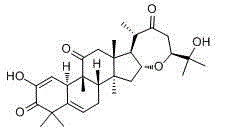

Cucurbitacins preparation method

A technology of snow cholestyramine and snow cholestasis, which is applied in the field of preparation of leucobilin A, and achieves the effects of short cycle, high efficiency and easy purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Get 2kg snow gall raw material and pulverize 60 meshes, put into supercritical CO2 extraction kettle, pass into liquid CO2, flow rate is 2ml / min / g raw material, pass into methanol as entrainer, flow rate is 0.3ml / min / g, at pressure 21MPa, Under the condition of temperature of 50°C, extract for 100 minutes, analyze the extract, heat dissolve with 90% ethanol and add an equal volume of petroleum ether, then add 1 / 3 volume of aqueous solution, mix well, static layer, collect the petroleum ether layer to recover the reagent, Reflux and dissolve with 90% ethanol solution, then add activated carbon to decolorize, concentrate 1 / 4 volume of the decolorization solution and place it to crystallize, then recrystallize the crystals with 95% ethanol solution, and dry to obtain 6 g of ichorin A, which is detected by high performance liquid phase. 98.3%.

Embodiment 2

[0015] Get 2kg snow gall raw material and pulverize 60 meshes, put into supercritical CO2 extraction kettle, pass into liquid CO2, flow rate is 1ml / min / g raw material, pass into methanol as entrainer, flow rate is 0.2ml / min / g, at pressure 25MPa, Under the condition of 45°C, extract for 60 minutes, analyze the extract, heat dissolve it with 95% ethanol and add an equal volume of petroleum ether, then add 1 times the volume of aqueous solution, mix well, static layer, collect the petroleum ether layer to recover the reagent, and then Reflux and dissolve with 95% ethanol solution, add activated carbon to reflux for decolorization, concentrate 1 / 4 volume of the decolorization solution and place it for crystallization, then recrystallize the crystals with 90% ethanol solution, dry to obtain 5.6 g of ichorin A, which is detected by high performance liquid phase. The content is 97.3%.

Embodiment 3

[0017] Get 2kg snow gall raw material and pulverize 40 meshes, put into supercritical CO2 extraction kettle, pass into liquid CO2, flow rate is 5ml / min / g raw material, pass into methanol as entrainer, flow rate is 0.1ml / min / g, at pressure 15MPa, Under the condition of temperature 30°C, extract for 150min, analyze the extract, heat dissolve with 95% ethanol and add an equal volume of petroleum ether, then add 1 / 2 volume of aqueous solution, mix well, static layer, collect the petroleum ether layer to recover the reagent, Reflux and dissolve with 95% ethanol solution, add activated carbon to reflux for decolorization, concentrate 1 / 3 of the volume of the decolorization solution and place it for crystallization, then recrystallize the crystals with 95% ethanol solution, dry to obtain 6.7g of ichorin A, which is detected by high performance liquid phase , content 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com