Patents

Literature

55 results about "Cucurbitacins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

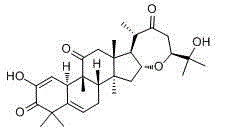

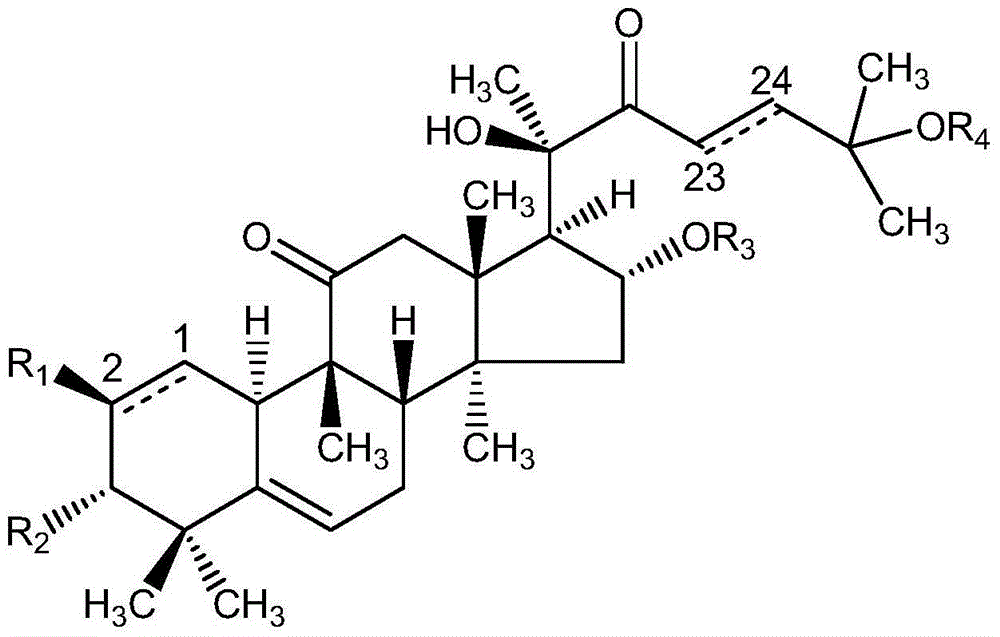

Triterpenes that derive from LANOSTEROL by a shift of the C19 methyl to the C9 position. They are found in seeds and roots of CUCURBITACEAE and other plants and are noted for intense bitterness.

Application of tetracyclic triterpenoids compound in preparing anti-angiogenic drugs

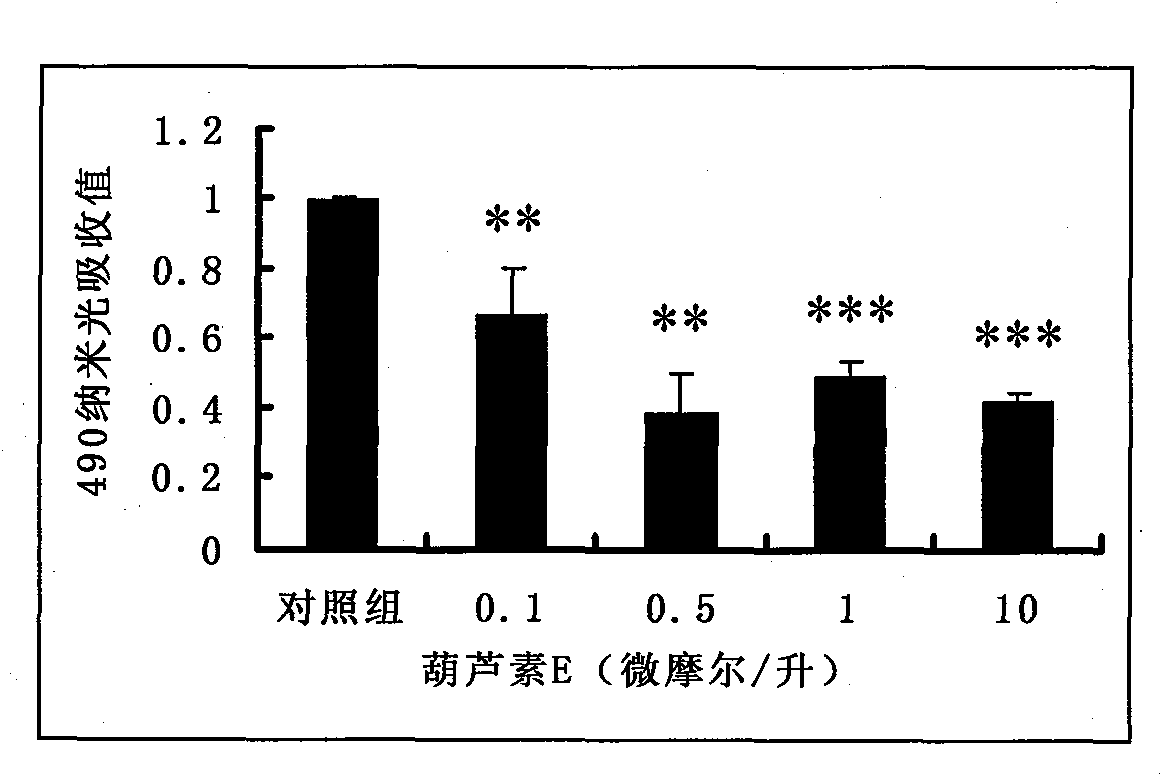

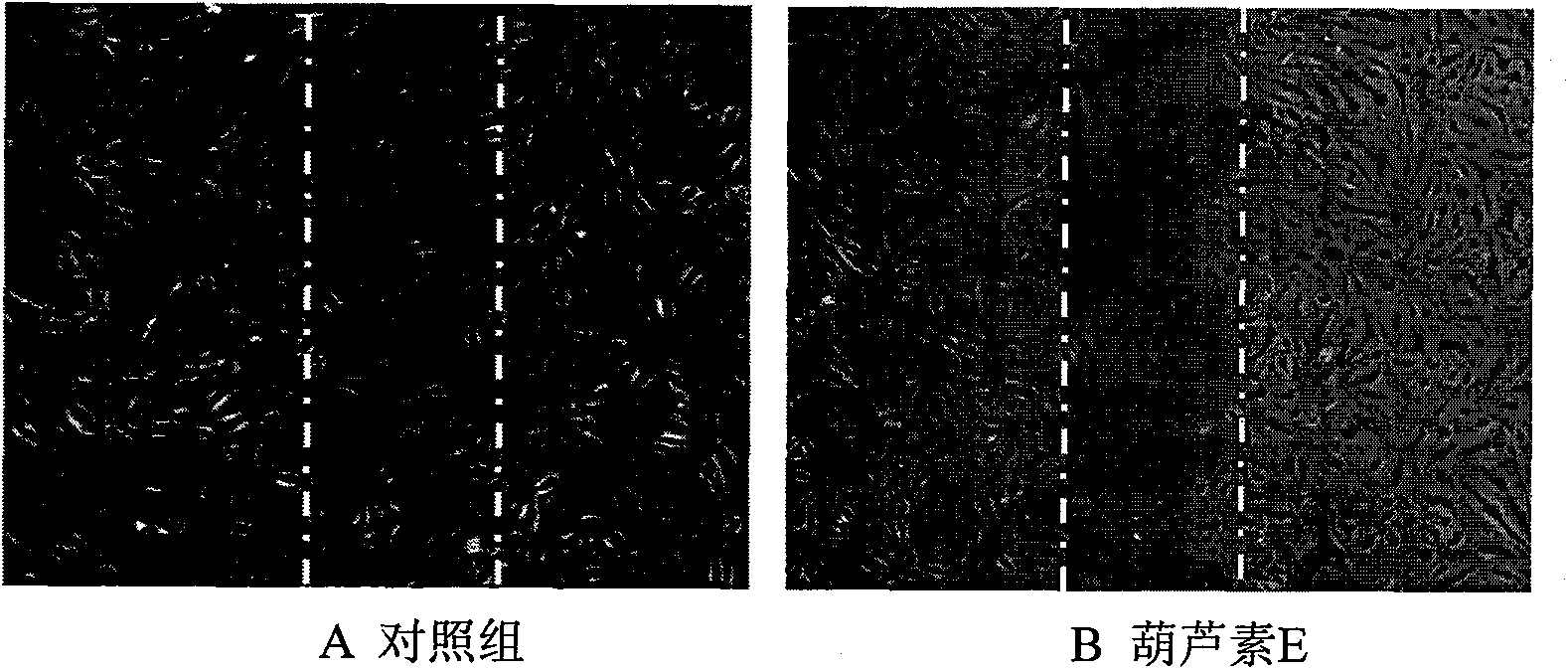

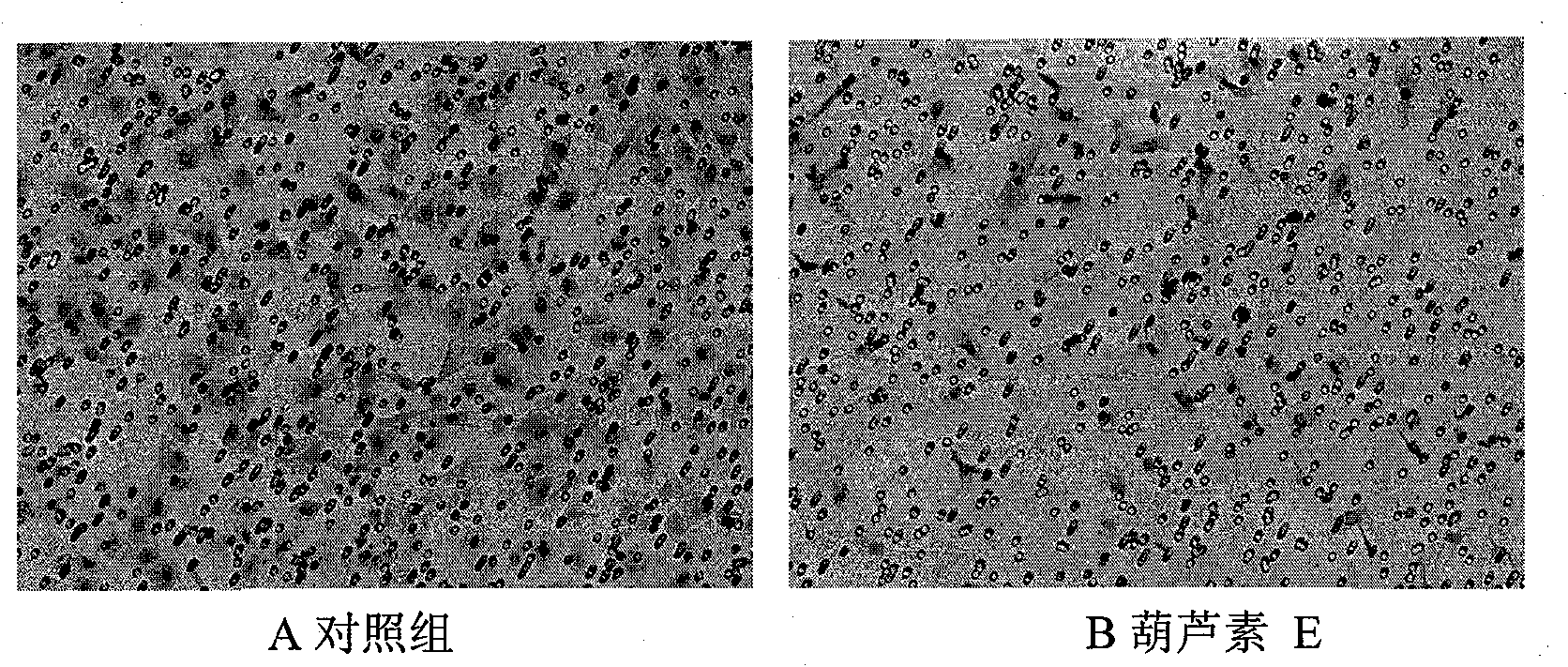

InactiveCN101647801AEnhanced inhibitory effectOrganic active ingredientsSenses disorderDiseaseAdditive ingredient

The invention provides the application of tetracyclic triterpenoids compound cucurbitacins E in preparing anti-angiogenic drugs. The cucurbitacins E can inhibit tumor angiogenesis, arthritis pathological tissue vessel angiogenesis, neovascular eye disease, hemangioma pathological tissue angiogenesis, psoriasis pathological tissue vessel angiogenesis, solid tumor pathological tissue angiogenesis, hemangioma, Kaposi' s sarcoma pathological tissue angiogenesis, leukocythemia, lymphadenoma, myeloma blood cancer and Paget' s disease angiogenesis. The invention also provides the application of a compound containing effective dose of cucurbitacins E and pharmacy acceptable ingredients in preparing the anti-angiogenic drugs.

Owner:EAST CHINA NORMAL UNIVERSITY

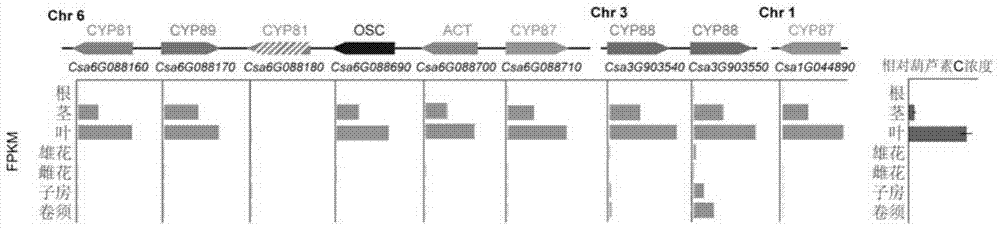

Gene cluster participating in synthesis of cucurbitacin E of watermelon and application of gene cluster

InactiveCN105039274ASpeed up the breeding processAchieve in vitro synthesisFungiTransferasesBiotechnologyHeterologous

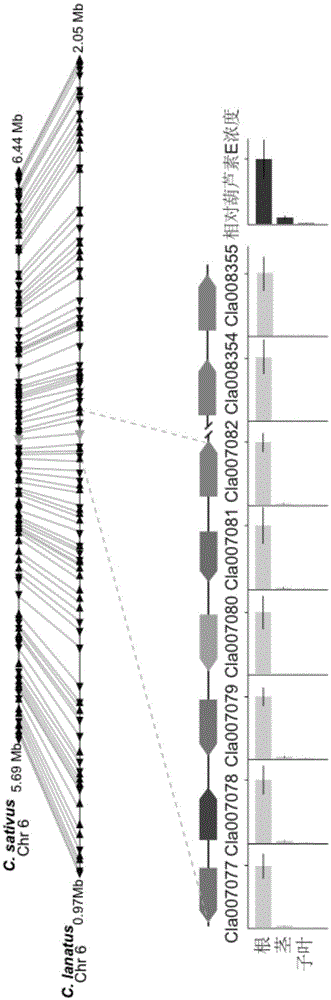

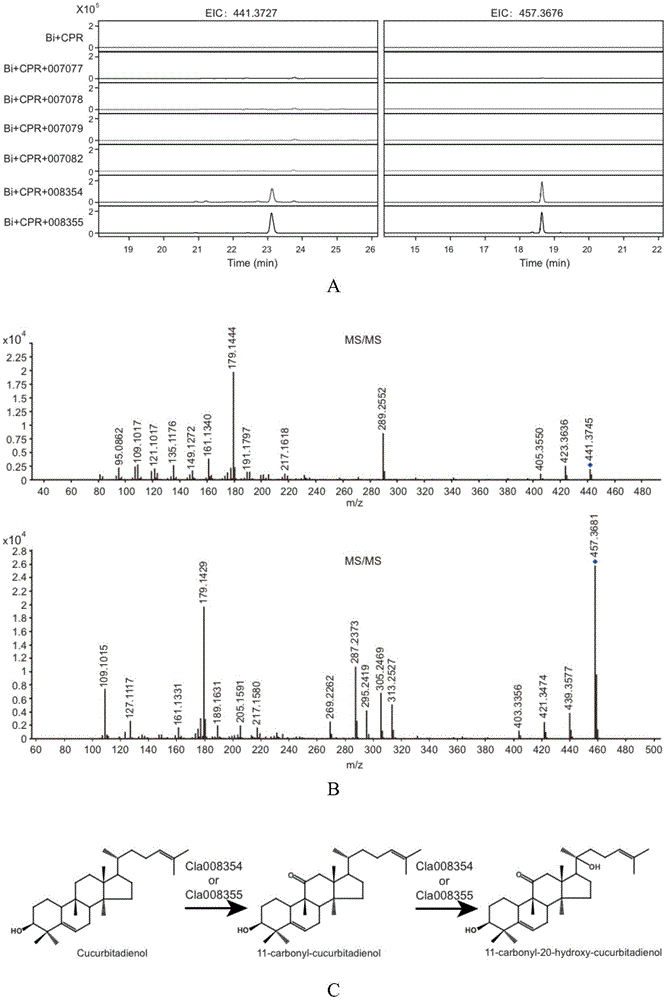

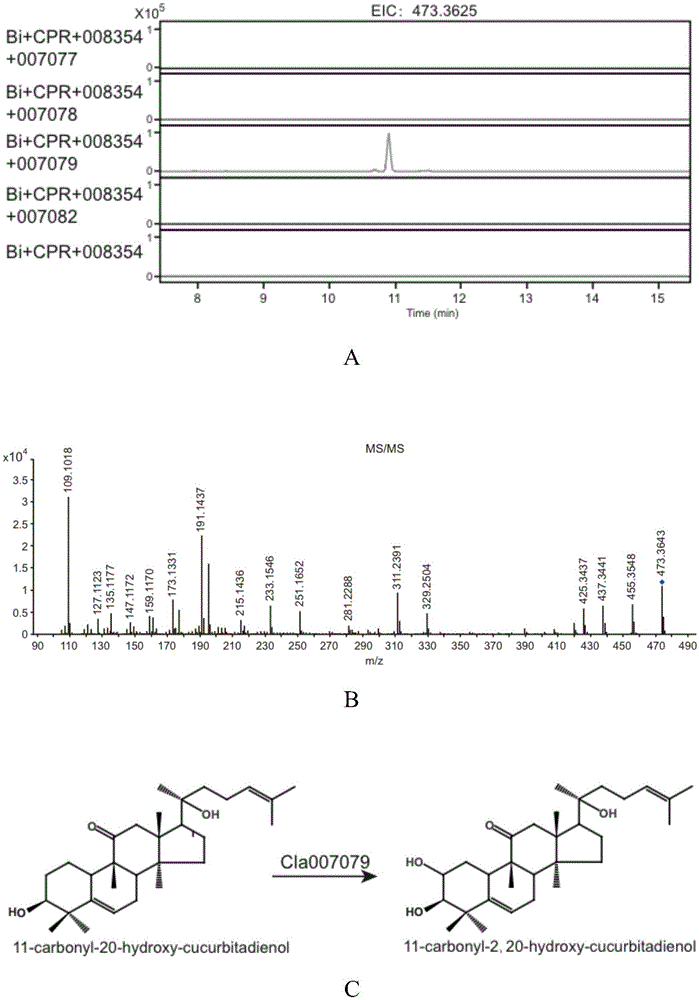

The invention relates to a gene cluster participating in synthesis of cucurbitacin E of watermelon and an application of the gene cluster. According to the invention, the gene cluster participating in synthesis of cucurbitacin E is found in the watermelon genome for the first time, the gene cluster comprises eight genes, wherein six of the eight genes are positioned within the range of the No.6 chromosome 57kb. A yeast system is adopted for analyzing the reaction from the step 1 to the step 4 of the synthesis of cucurbitacin E. The invention further discloses a molecular mechanism for forming the bitter taste of the watermelon, so that a theoretical basis and a molecule assistant breeding objective are provided for the breeding of the watermelon without the bitter taste, and valuable experiences are provided for heterologous biosynthesis and development and utilization of cucurbitacine. The technology provided by the invention can replace the traditional method for extracting bitter principle from a plant material, so that synthesis of the bitter principle in vitro is realized by utilizing synthetic biology.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

Bait with cucurbitacin

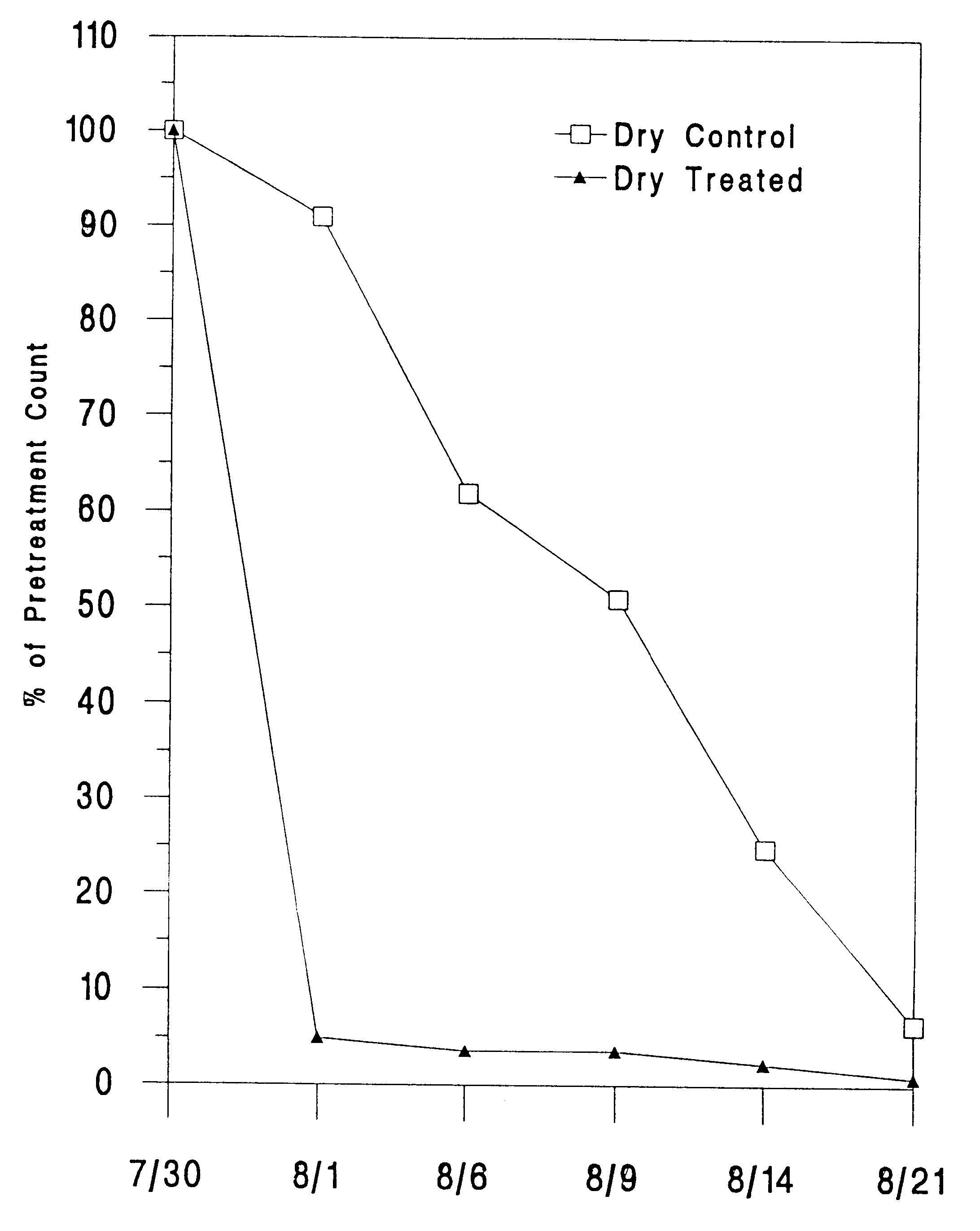

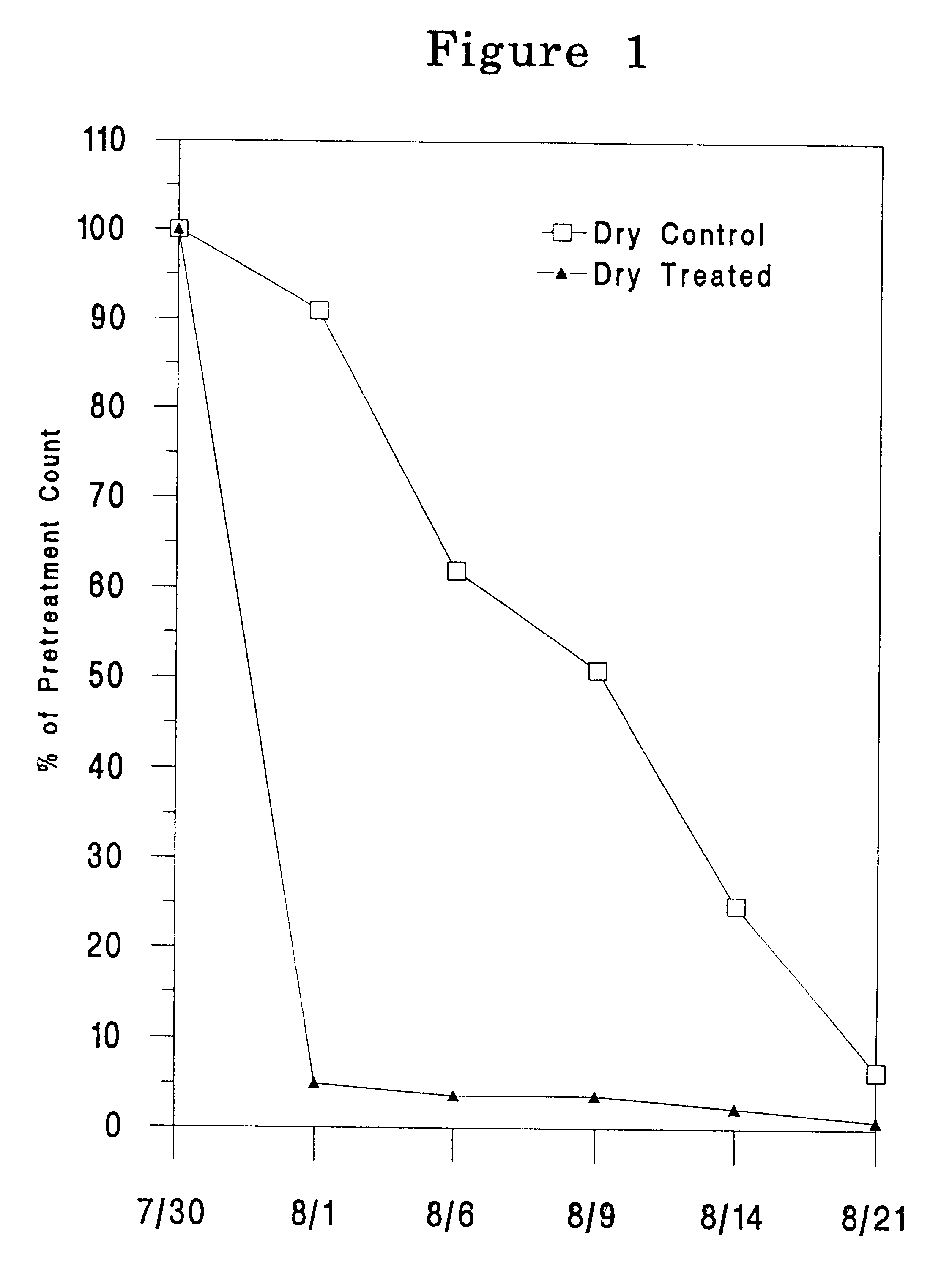

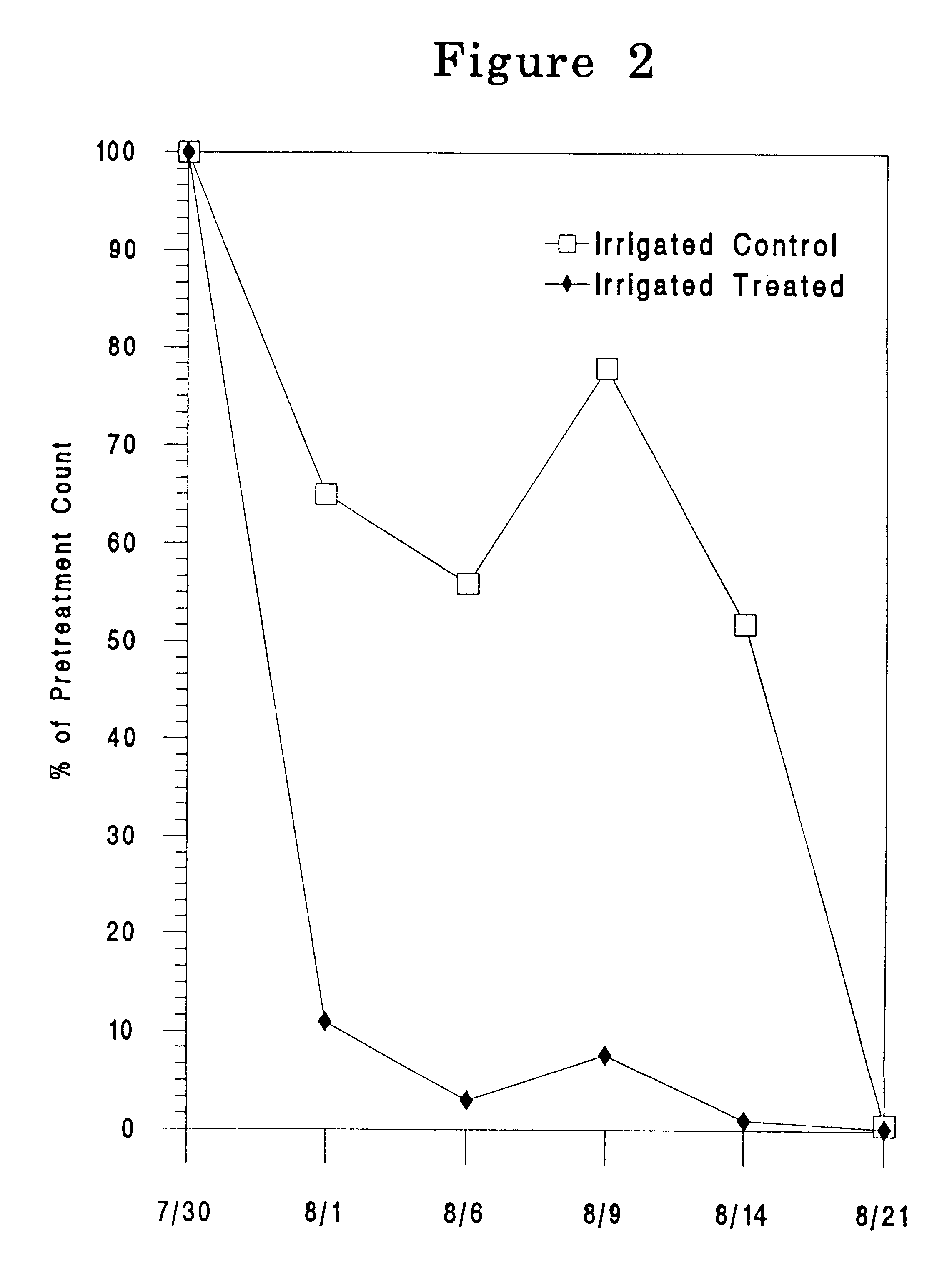

Baits useful against diabroticine mature and immature beetles contain (a) an insecticide and (b) a feeding stimulant containing a cucurbitacin in a gelatin binder.

Owner:BARNETT BANK OF POLK COUNTY

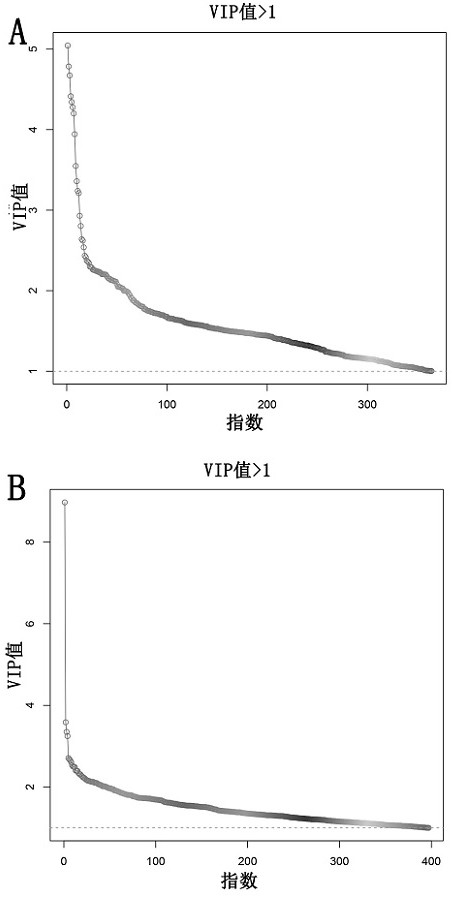

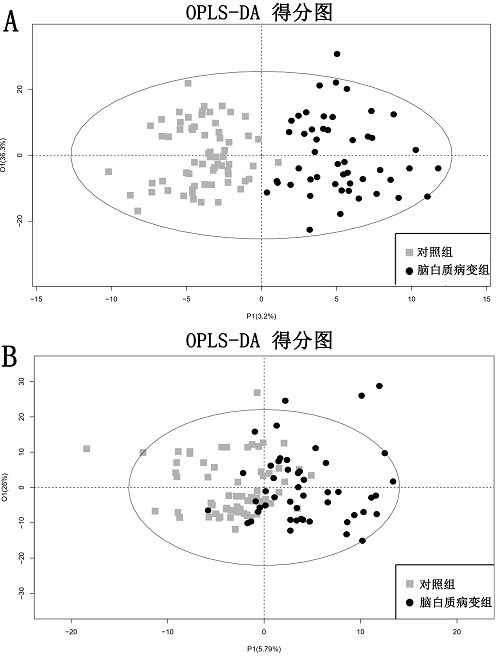

Biomarker for diagnosing white matter lesion and application thereof

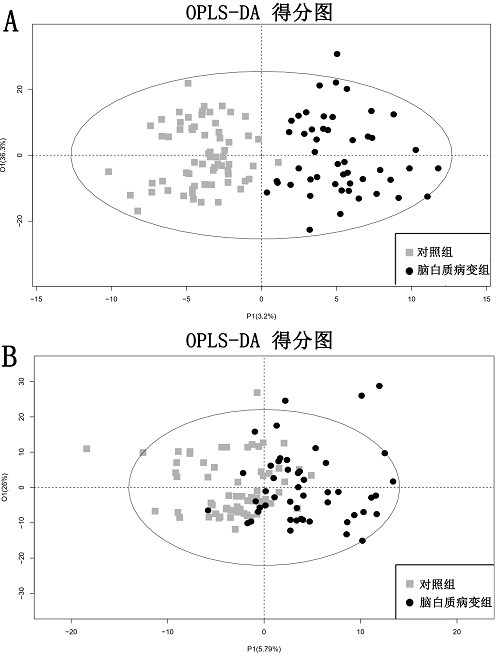

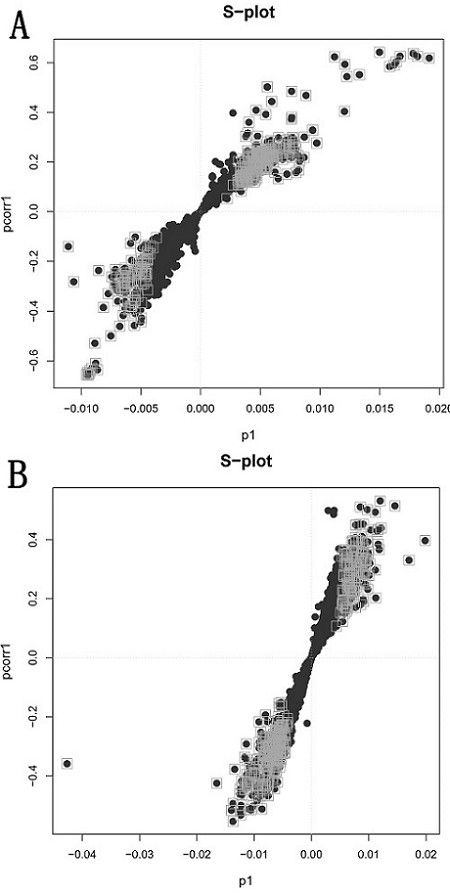

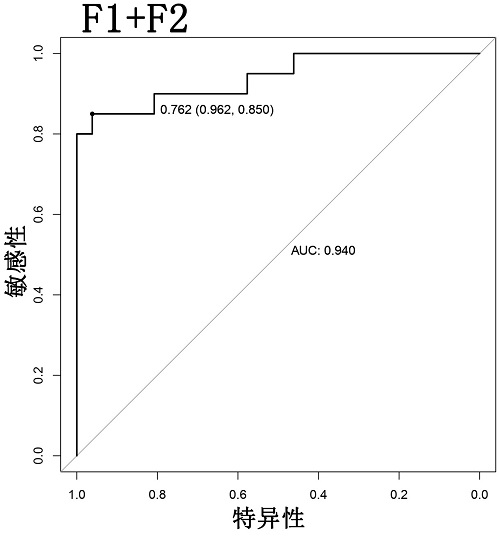

The invention provides a biomarker for diagnosing white matter lesion and application thereof. The biomarker is cholesterol-alpha-D-glucoside. The biomarker cholesterol-alpha-D-glucoside is combined with 6Z,9Z,20-eicosatrienoic acid, ceramide (m18:1(4E) / 24:1(15Z)), ephedrine A, cucurbitacine E, cholesteryl ester 22:6 or ceramide (d18:0 / 24:1(15Z)) to judge whether white matter lesion exists or not. The biomarker for diagnosing the white matter lesion is used for preparing a detection reagent for diagnosing the white matter lesion, and is beneficial for diagnosing whether the white matter lesion tends to exist or not and preventing the white matter lesion in advance.

Owner:BAO FENG BIOTECH (BEIJING) CO LTD

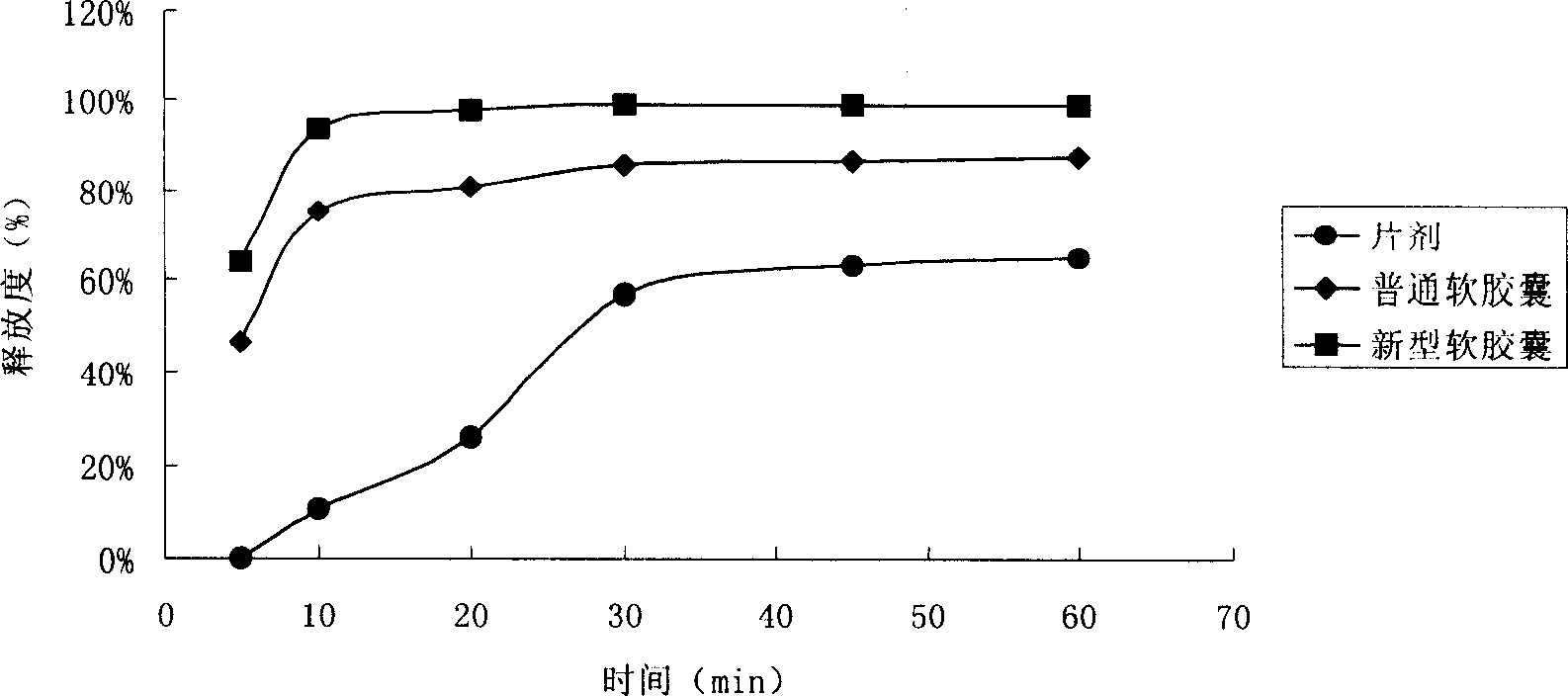

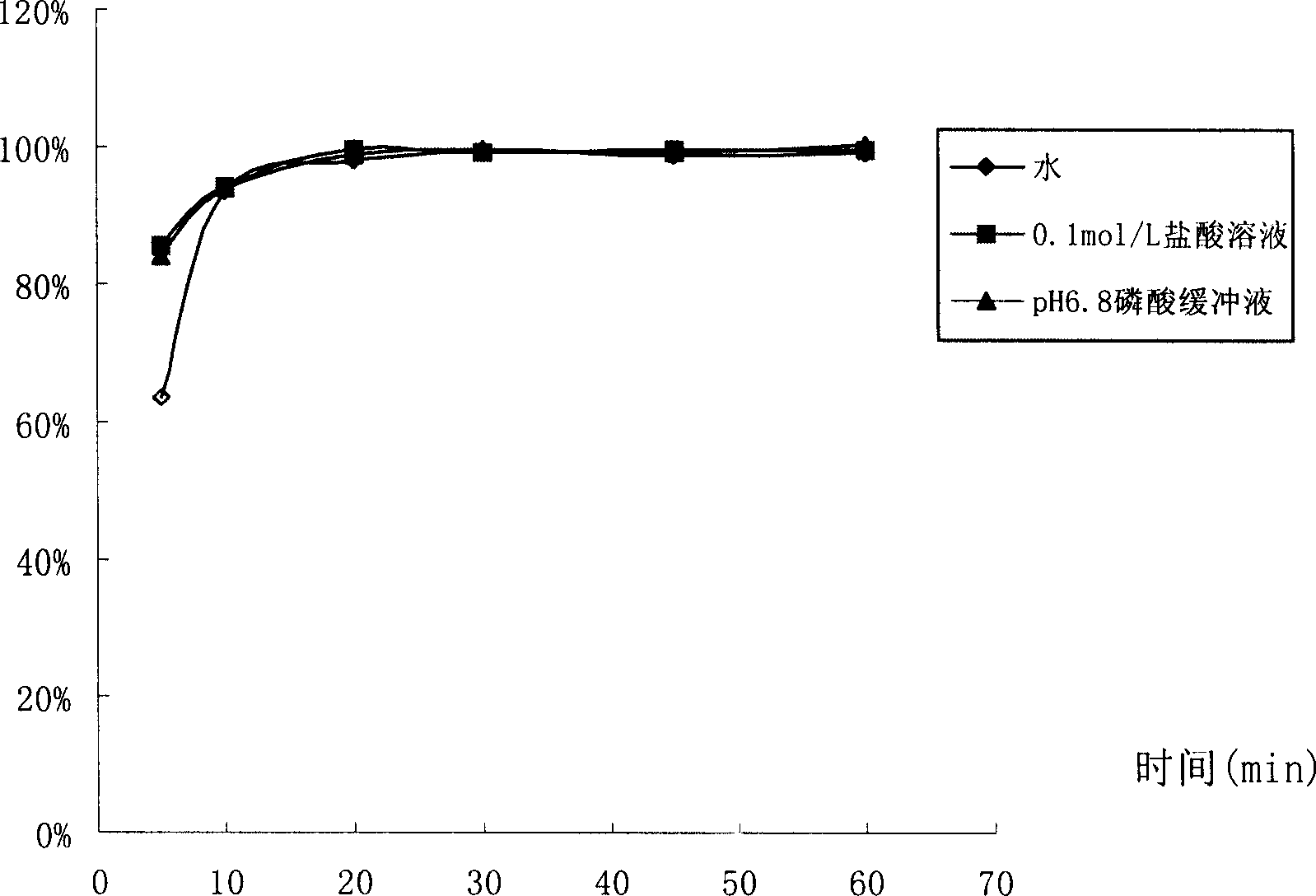

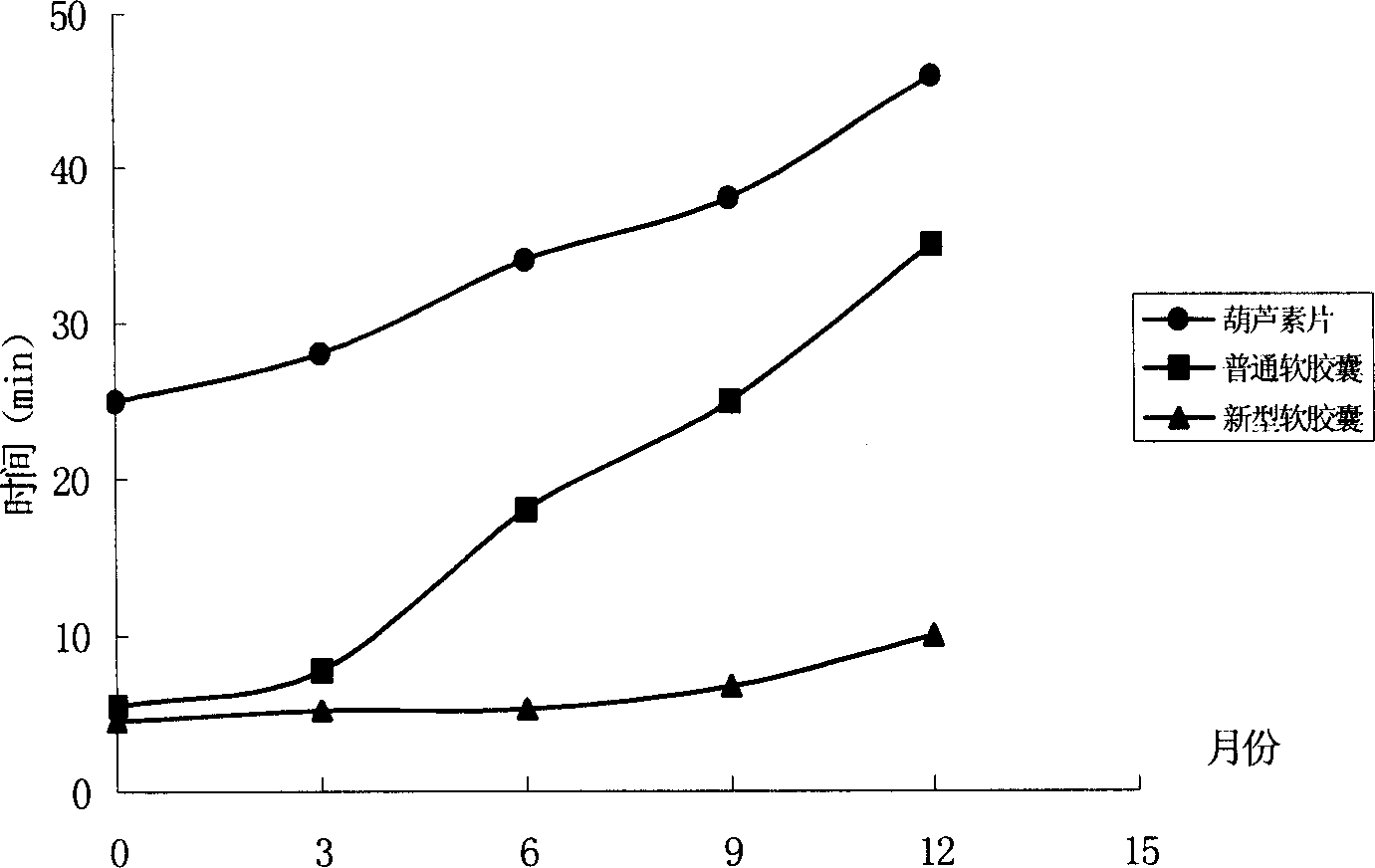

Cucurbitacin soft capsule and its preparation process

InactiveCN1839849AOvercoming various deficiencies of poor bioavailabilityOral convenienceOrganic active ingredientsDigestive systemSolventBiomedical engineering

The invention relates to a cucurbitacin soft capsule oral medicament and process for preparation, wherein the medicament includes medicinal soup and capsule shell, wherein each tablet of the soup comprises micronized cucurbitacin 0.01-10mg, dissolvent and stabilizing agent, the shell contains gelatin, plasticizing agent, preservative agent, screening agent, flavoring agent and coloring matter.

Owner:安徽省现代中药研究中心

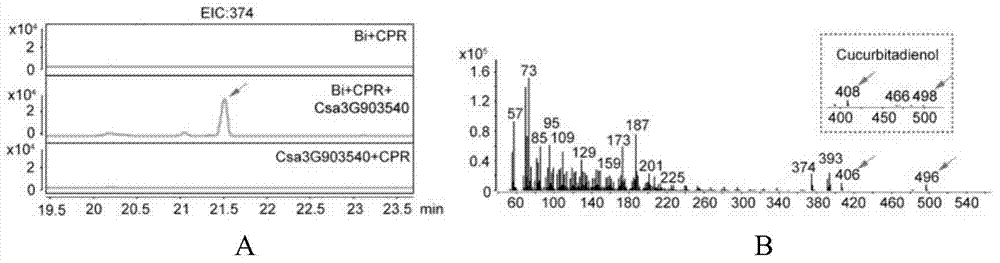

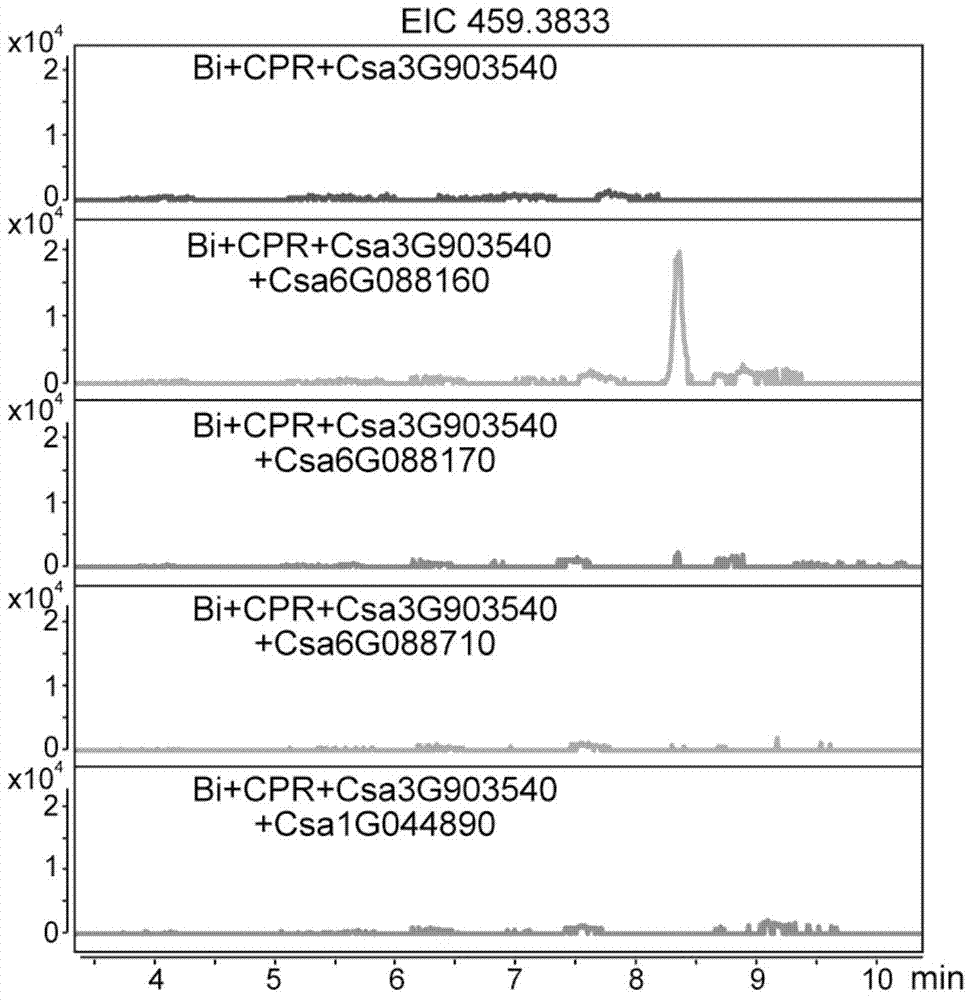

Gene cluster participating in synthesis of cucumber cucurbitacine C and application thereof

ActiveCN103483435AAchieve synthesisAchieve in vitro synthesisPlant peptidesFermentationYeastNicotiana tabacum

The invention discovers a gene cluster participating in synthesis of cucurbitacine C in a cucumber genome for the first time. The gene cluster totally consists of 8 genes, wherein 5 genes are located in a 35kb range of No. 6 chromosome. The 1st to 4th steps of reaction for synthesizing cucurbitacine C are analyzed in a yeast system, and the 8 genes are co-expressed in a tobacco system, so that synthesis of cucurbitacine C can be realized. The invention further discloses a molecular mechanism of cucumber bitter formation, which provides a theoretical basis and a molecular aided breeding goal for breeding bitter-free cucumber; meanwhile, precious experience is provided for in-vitro artificial synthesis of cucurbitacine.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI

Biomarker for diagnosing white matter lesion and application thereof

Owner:BAO FENG BIOTECH (BEIJING) CO LTD

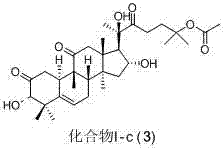

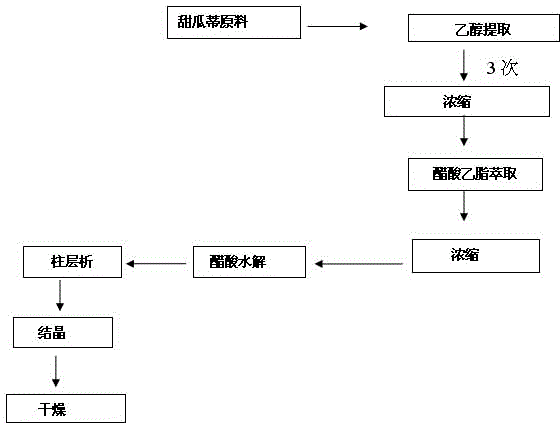

Preparation and application of pedicellus melo tetracyclic triterpenoid cucurbitacin type compound

InactiveCN103360452AProlong replicative lifespanOrganic active ingredientsAntinoxious agentsAge related diseaseSolvent

The invention provides a preparation method of a cucurbitacin type compound. The preparation method comprises the steps of extracting pedicellus melo by using an organic solvent, performing solvent distribution on an extract, and performing silica gel column separation and purification by high performance liquid chromatography on a sample after concentration to obtain a cucurbitacin mixture and a cucurbitaceae type compound. Through an anti-aging yeast model-K6001 yeast cell, an active ingredient, namely the cucurbitacin type compound is proved to be capable of significantly prolonging the replicative life span of yeast, so that the cucurbitacin mixture and the cucurbitaceae type compound can be applied in preparation of medicaments for preventing and treating aging and preventing or / and treating age-related diseases. Simultaneously, the cucurbitacin mixture and the cucurbitaceae type compound can also be applied in preparation of nutritional compositions for delaying aging and preventing age-related diseases. The compound can also be used as a lead compound for optimizing the structure and can be applied in preparation of medicaments for delaying aging and preventing or / and treating age-related diseases. The general formula of the structure of the compound is shown in the specification.

Owner:ZHEJIANG UNIV +1

Pet feed

InactiveCN102972625AMeet growth and development needsReasonable deploymentFood processingAnimal feeding stuffAnimal scienceLycopene

The present invention relates to a feed, and particularly relates to a nutritionally balanced pet feed. The present invention includes 5-8% of plant fiber; 15-20% of potato flour; 3-5% of poria powder; 1-2% of tangerine peel powder; 5-10% of egg white powder; 0.2-1% of vitamins; 1-4.5% of bone meal; 0.2% of salt; 15-20% of animal fat; 0.2-0.5% of cucurbitacine; 0.1-0.5% of lycopene; 0.5% of sugar; and the balance being corn flour. The above compositions are formulated by weight. The pet feed is nutrient-rich, is reasonable in nutrient allocation, can meet the pet growth and development needs, and is added with lycopene and cucurbitacine which can detoxify and improve body function. The Chinese herbal medicinal ingredients like poria and tangerine peel have the efficacy of strengthening spleen and stomach and improving the nutrient absorption capacity.

Owner:SHENYANG XINDA INFORMATION SCI & TECH

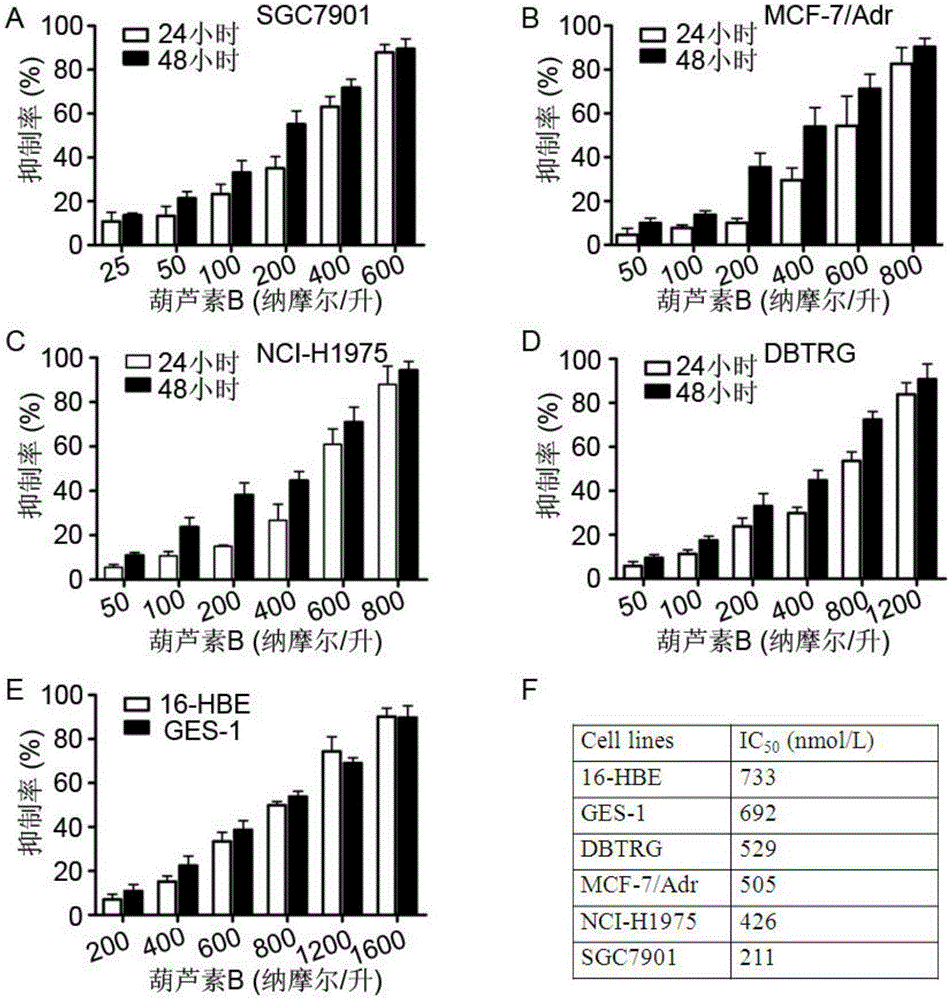

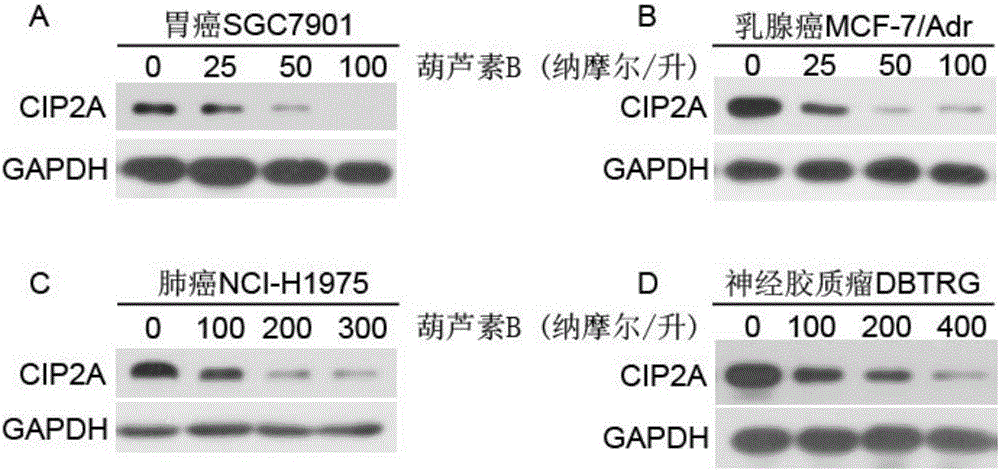

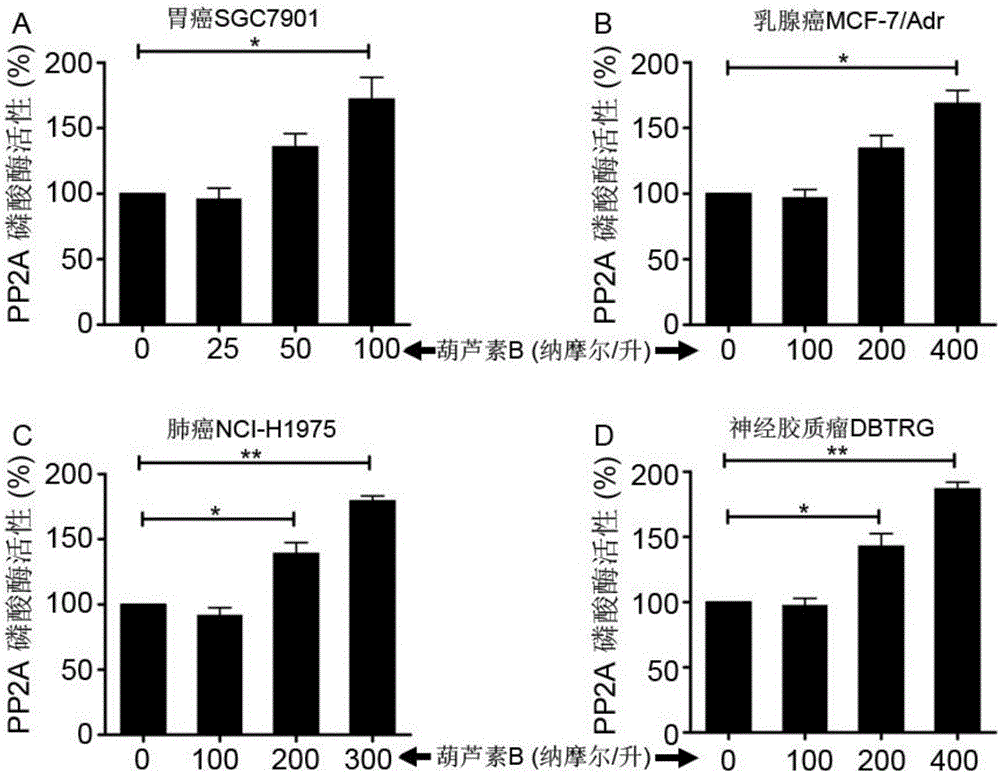

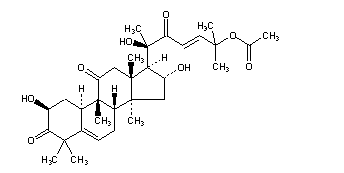

Application of cucurbitacine B to preparation of cancerous inhibitor of protein phosphatase 2A

InactiveCN106074567ASignificant effectNo obvious side effectsOrganic active ingredientsAntineoplastic agentsCombined treatmentWilms' tumor

The invention belongs to the technical field of medicine, and particularly relates to an application of tetracyclic-triterpene-like compound-like cucurbitacine B separated and extracted from cucurbitaceous plants as a cancerous inhibitor of protein phosphatase 2A. Cucurbitacine B is taken as a main component in the cancerous inhibitor of protein phosphatase 2A, so that the expression of the cancerous inhibitor of protein phosphatase 2A can be inhibited remarkably. The cucurbitacine B can be applied to independent administration or combined treatment, including combined applications with radiotherapy, chemotherapy, surgical treatment, other growth factor inhibitors and sexual hormone inhibitors, any tumor treatment medicament and method.

Owner:HUBEI UNIVERSITY OF MEDICINE

Stable liquid curbitacin preparation and method for preparing same

InactiveCN101579370AGood synergyGood treatment effectDigestive systemSolution deliveryDiseaseSoftgel

The invention relates to a stable liquid curbitacin preparation which contains curbitacin and Brucea javanica oil and can also contain other liquid fatty oil and / or antioxidant. The invention also relates to a medicament taking the stable liquid curbitacin preparation as an active component. The medicament can be the injection, the oral medicament, the dropping pill, the emulsion, the soft capsule, the hard liquid capsule or the suspension. The stable liquid curbitacin preparation has the efficacy of treating the hepatitis, the cirrhosis, the tumour, the cancer and the like; the curbitacin and the Brucea javanica oil can interact synthetically; and the Brucea javanica oil can well solve the curbitacin and prevent the curbitacin from being oxidized.

Owner:BEIJING SHENKELIANHUA TECH

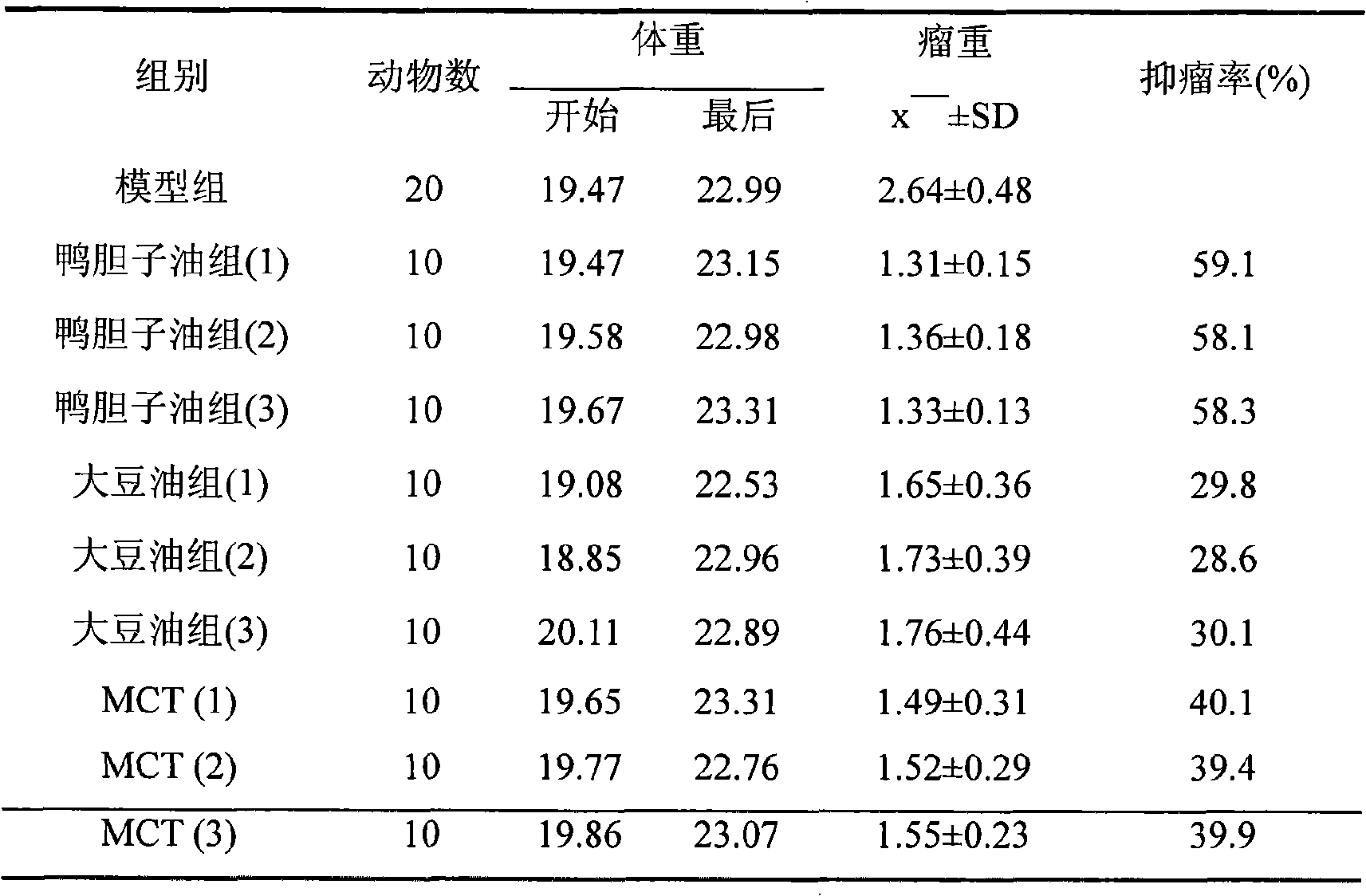

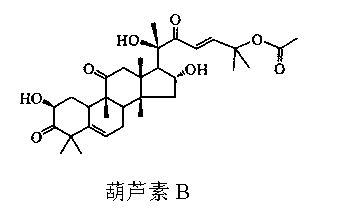

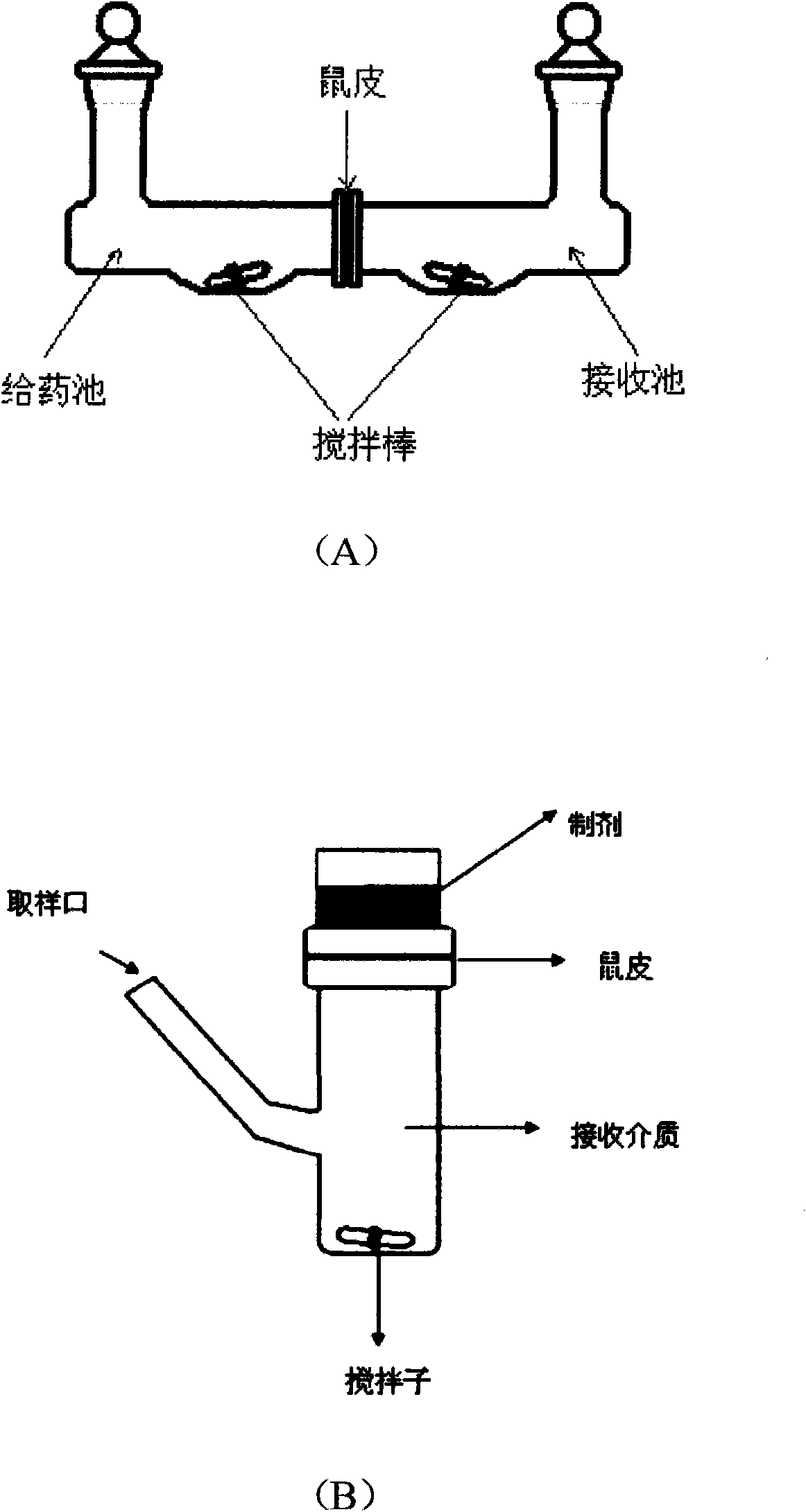

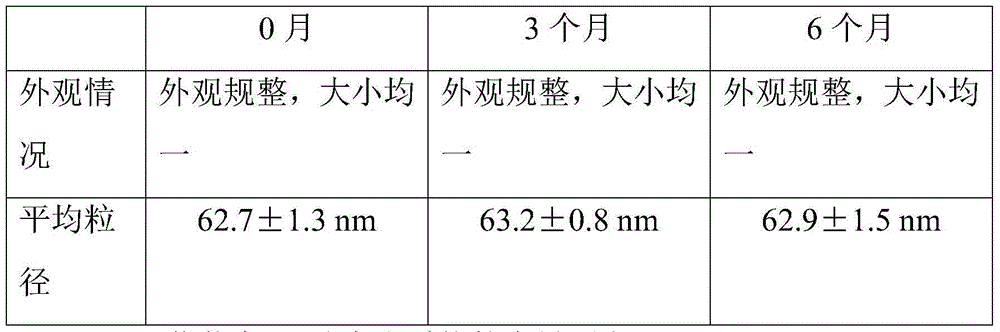

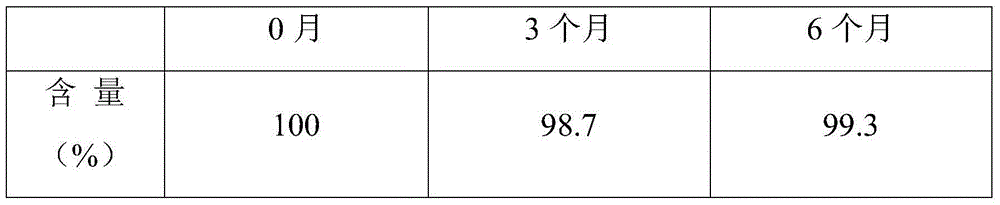

Cucurbitacin oral lipid nano emulsion and preparation method

InactiveCN103169656AMedication convenienceImprove complianceOrganic active ingredientsDigestive systemMedium-chain triglyceridePharmaceutical Substances

The invention discloses a prescription for preparing a cucurbitacin oral lipid nano emulsion and a preparation method. The cucurbitacin oral lipid nano emulsion contains cucurbitacin, medium chain triglyceride, soya lecithin, polyoxyethylene 40 hydrogenated castor oil, an antifreezing agent, vitamin E and water. The prepared cucurbitacin oral lipid nano emulsion has good antifreezing capability, Compared with the tablet in the market, the disintegration of the tablet in the gastrointestinal tract is not existed, the dissolution of the medicine is fast, the cucurbitacin oral lipid nano emulsion is widely and uniformly distributed in a easy mode, the acting time is fast, and the bioavailability of the cucurbitacin oral lipid nano emulsion is obviously enhanced. The preparation technology is simple, and can be used for industrial production.

Owner:SHENYANG PHARMA UNIVERSITY

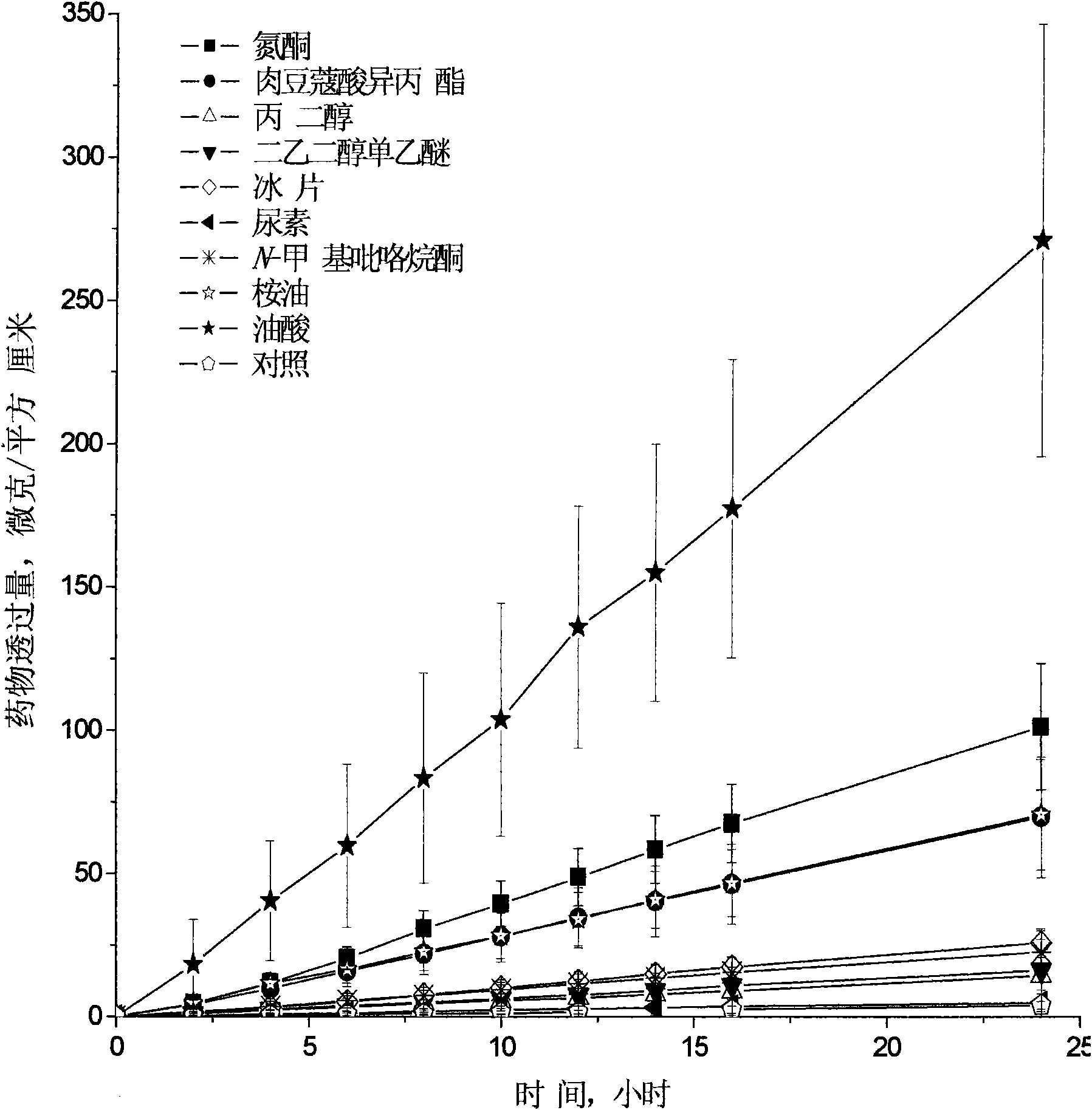

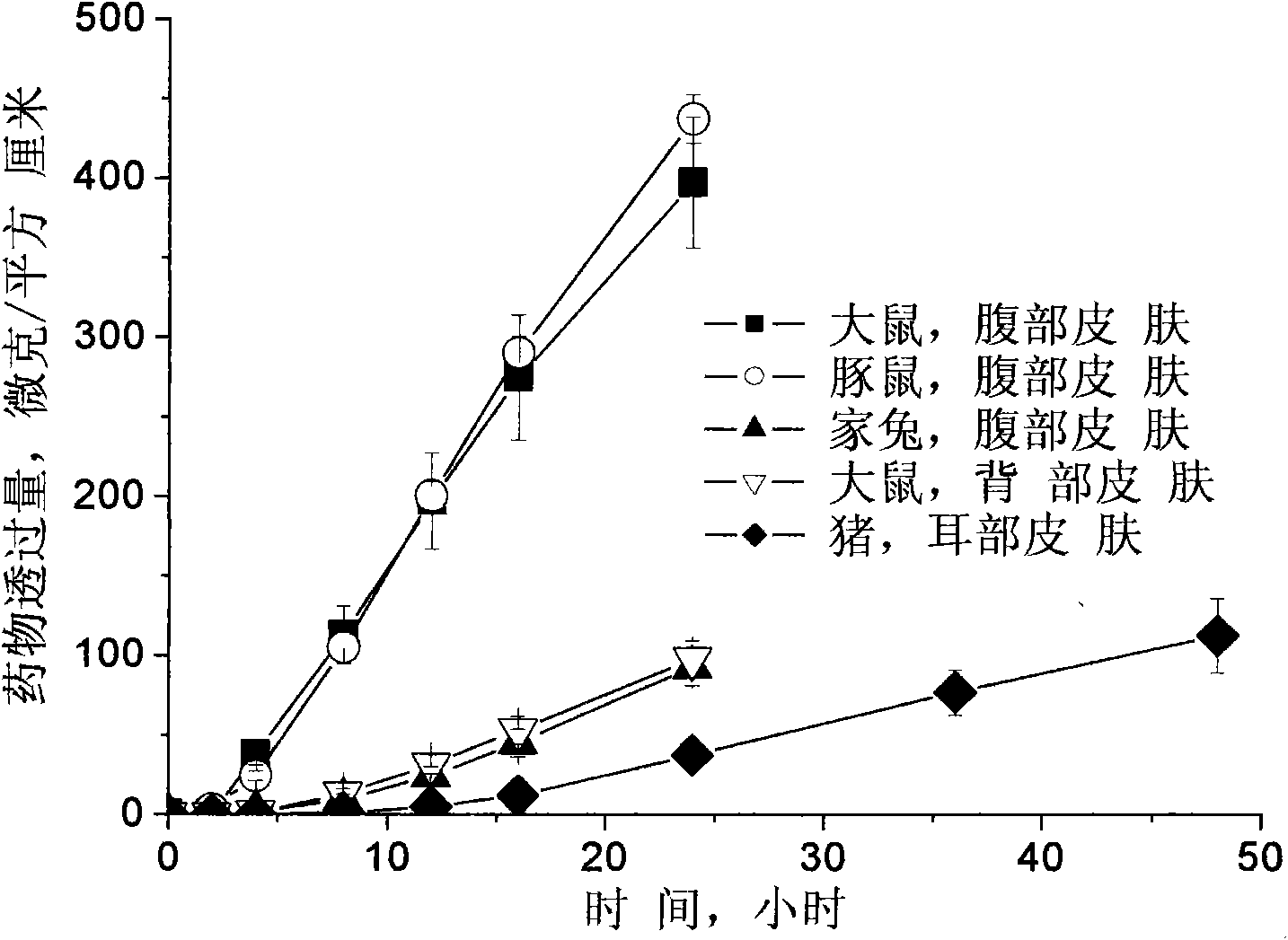

Transdermal administration composite containing cucurbitacin-type active ingredient

ActiveCN101623286ANon-irritatingImprove complianceOrganic active ingredientsDigestive systemDiseaseAdditive ingredient

The invention relates to a transdermal administration composite containing cucurbitacin-type active ingredient. The transdermal transparent accelerator in the transdermal administration preparation of the cucurbitacin-type active ingredient is one or more composites of oleic acid, azone, eucalyptus oil, or isopropyl myristate and the like, and the dosage of the transdermal transparent accelerator is 0.1 to 50%, and 0.3 to 30% is preferred. The transdermal administration of cucurbitacin-type active ingredient can adopt liquid or semisolid preparation of gels, emulsion, ointment, solution agent, micro-emulsion, ethosomes or nebula and the like, or emplastrum such as patch, cataplasma and the like. After the transdermal administration of the preparations, the active ingredient can be absorbed by skin continuously and enter into human body to play a therapeutic role for a long while, the patient adaptability is significantly better than oral administration medication, therefore, the transdermal administration composite can be used for preventing and curing of hepatitis, cancer and other diseases and improving quality life of patients.

Owner:SHENYANG PHARMA UNIVERSITY

Extracts of Aquilaria hulls and use thereof in the treatment of cancer

The invention discloses an ethyl acetate layer of methanol extract of Aquilaria hulls for killing cancer cells and treating / preventing cancers and its uses. The extracts of Aquilaria hulls has an significant amount of cucurbitacins and these cucurbitacins are effective in killing cancer cells and treating / preventing cancers.

Owner:TAIPEI MEDICAL UNIV

Cucurbitacine liposome and its prepn. method

InactiveCN1723906AImprove poor oral absorptionImprove curative effectOrganic active ingredientsDigestive systemChemistryWater soluble

A cucurbitacin lipid with high absorptivity, biologic utilization rate and stability for treating tumor and hepatitis and improving immunity is prepared proportionally from vinpocetin, phosphatide, cholesterol and the supporting agent chosen from sorbitol, mannitol, cane sugar, sodium chloride, water-soluble starch, etc.

Owner:胡才忠

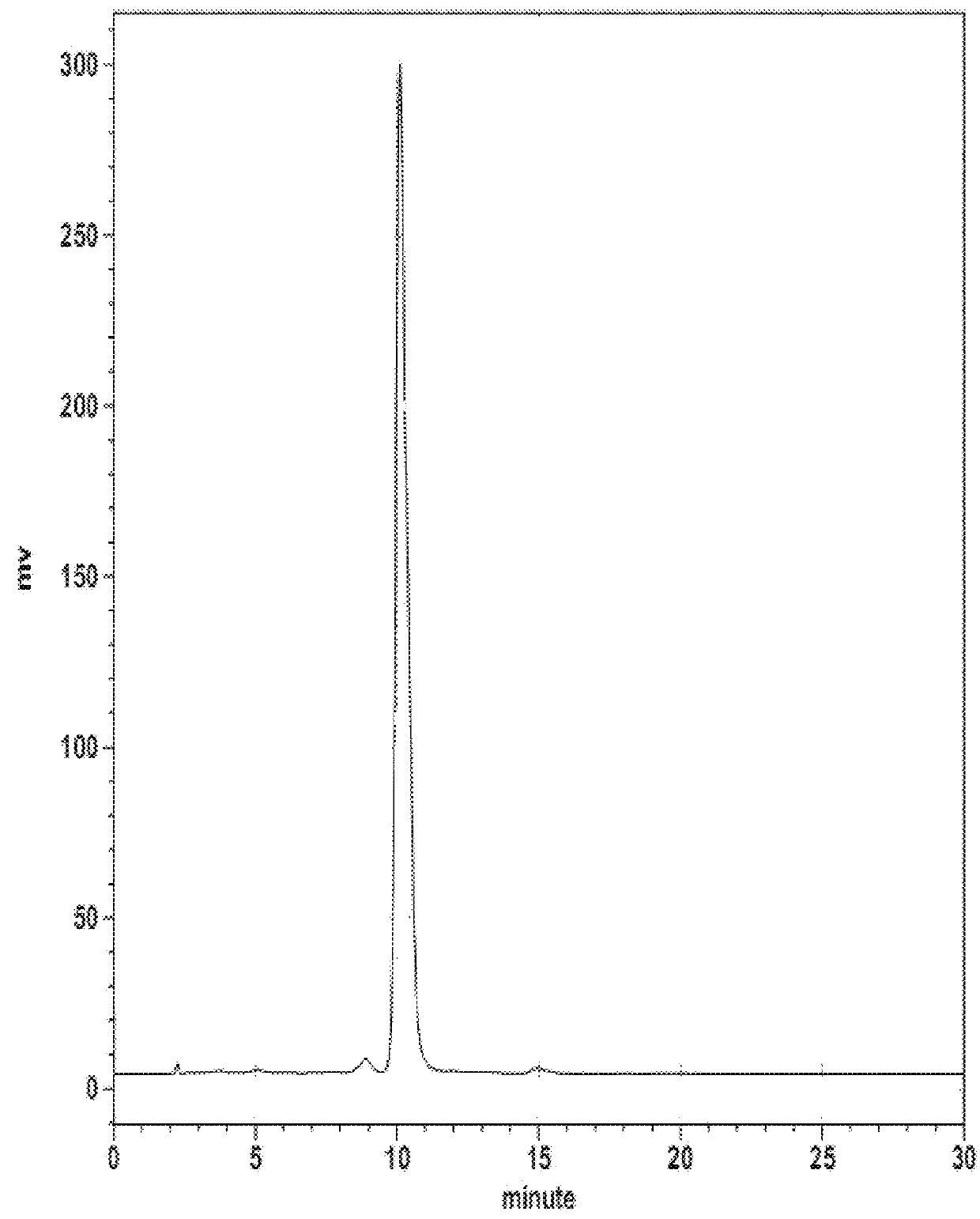

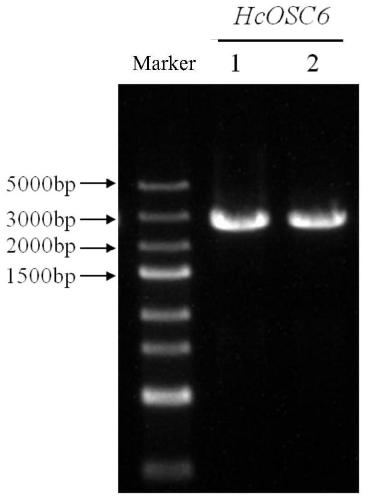

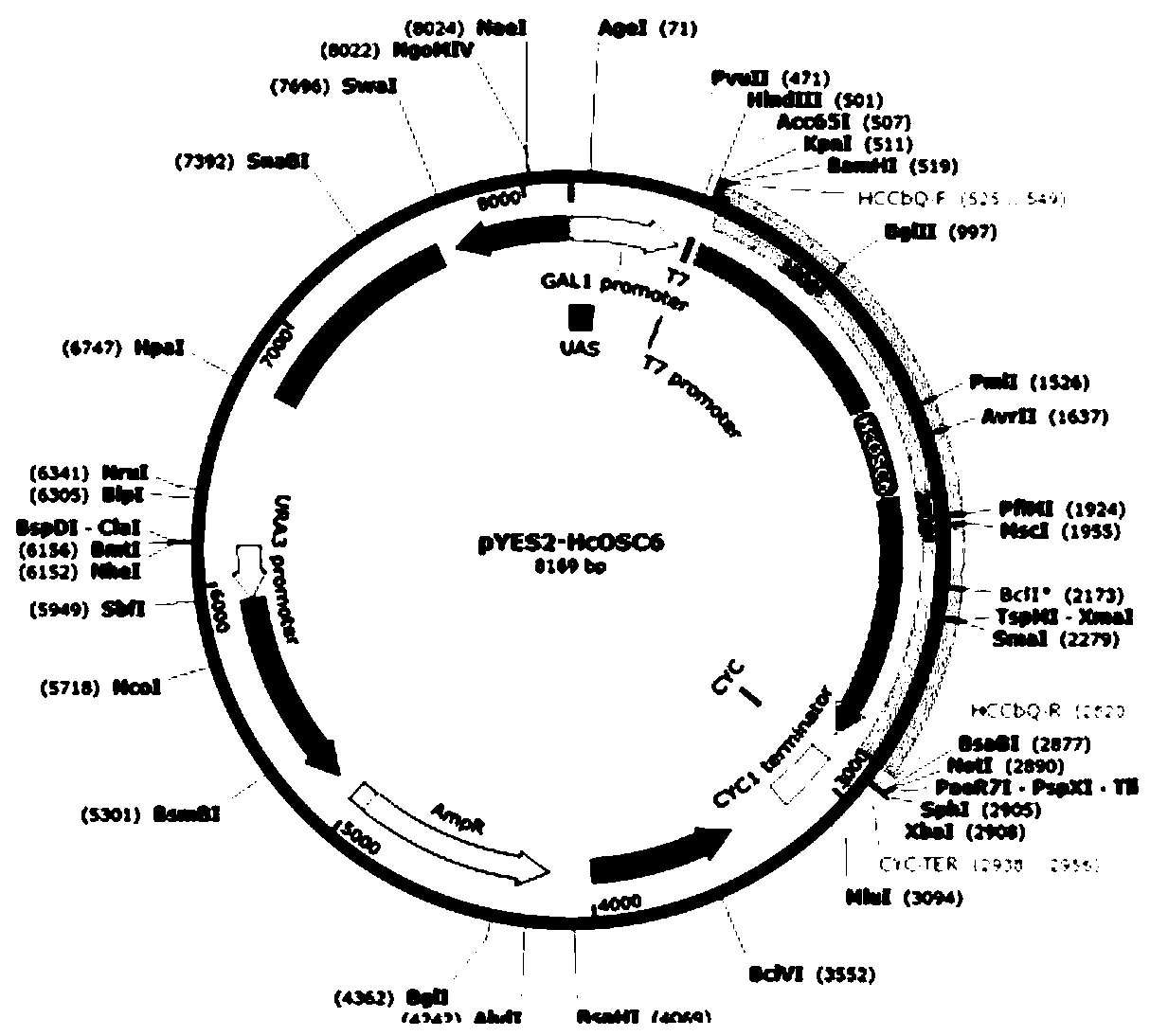

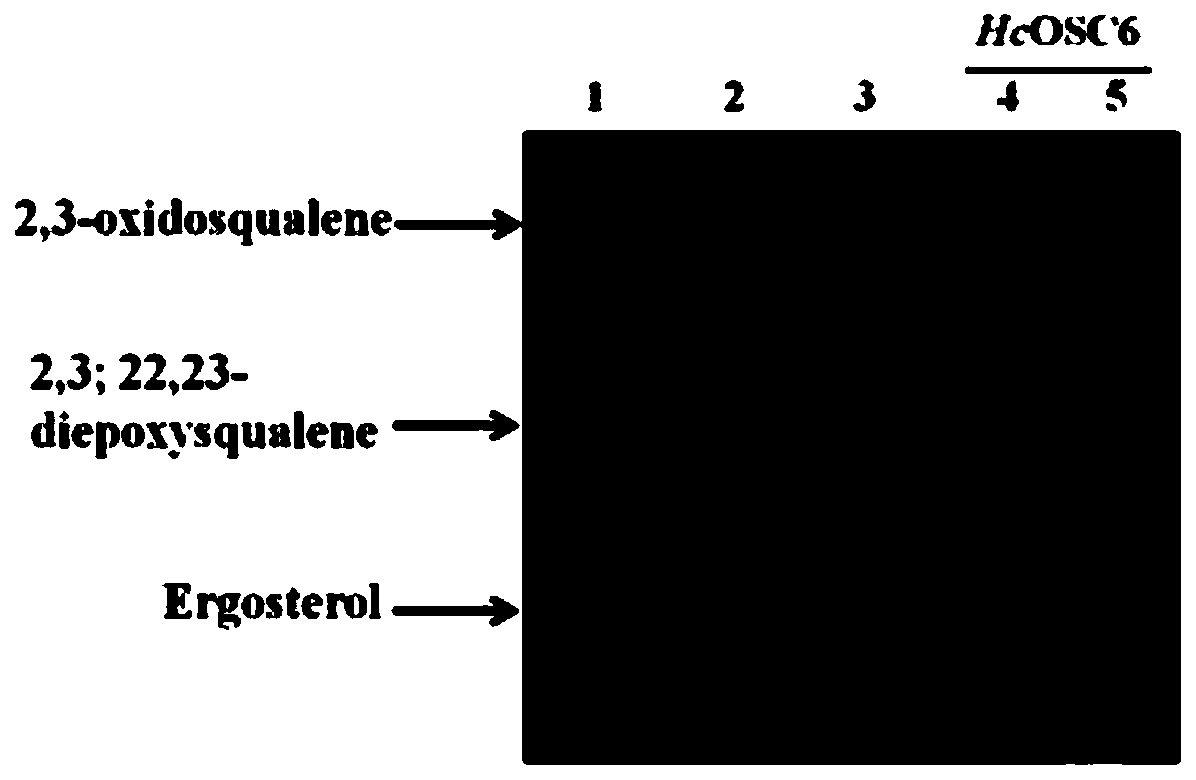

Hemsleya amabilis triterpene synthetase HcOSC6 gene and engineering bacteria thereof as well as application to preparation of gourd dienol

The invention discloses a hemsleya amabilis triterpene synthetase HcOSC6 gene and engineering bacteria thereof as well as an application to preparation of gourd dienol. The hemsleya amabilis triterpene synthetase HcOSC6 gene has a nucleotide sequence shown in SEQ ID No.1, and the engineering bacteria can express hemsleya amabilis triterpene synthetase HcOSC6. In a culture medium taking D-glucose and D-galactose as carbon sources, the genetically modified engineering bacteria can express hemsleya amabilis triterpene synthetase HcOSC6 in cells, under the catalysis of hemsleya amabilis triterpenesynthetase HcOSC6, an endogenous substrate squalene-2,3-oxide of yeast can be subjected to a cyclization reaction, and gourd dienol is produced and has the yield about 5.5 mg / L. An important way forproducing the gourd dienol is provided, and rich raw materials are provided for biological synthesis of cucurbitacin such as hemsleyadin and the like.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Cucurbitacin B nanometer liposome and preparation thereof

InactiveCN106137966AProlong the action timeReach the lesionOrganic active ingredientsPharmaceutical non-active ingredientsClearance ratePolyethylene glycol

The present invention relates to a cucurbitacin B liposome drug and preparation thereof. The invention provides a cucurbitacin B nanometer liposome drug and a preparation method thereof. According to the present invention, a passive drug delivery way is used, and a substance polyethylene glycol containing polyhydroxy groups is linked to the phospholipid phosphoric acid group to modify so as to prepare the long-circulating nanometer liposome, wherein the structural modification effect is to protect the liposome from being identified and uptaken by opsonin in blood so as to reduce the liposome clearance rate and prolong the residence time in the blood, such that the action time of the drug is prolonged, the liposome can effectively reach the lesion, and the selectivity on the targeted tissue can be improved; the preparation prepared by the preparation method has characteristics of good physical stability, good chemical stability, long residence time in the body, small distribution volume in the body, and high blood drug concentration in the body; the drug of the present invention can be used for treatment of various types and various stages of liver cancers; and the cucurbitacin B liposome drug has characteristics of scientific formula, convenient use, good stability and low toxicity, and the preparation method is suitable for large-scale production.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

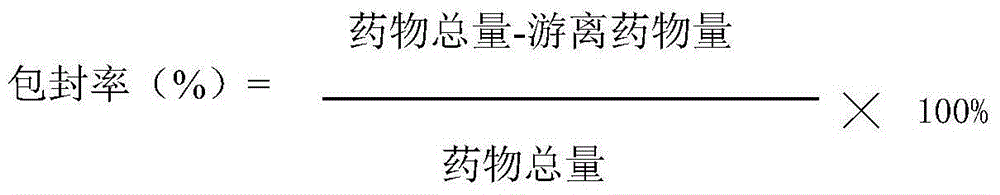

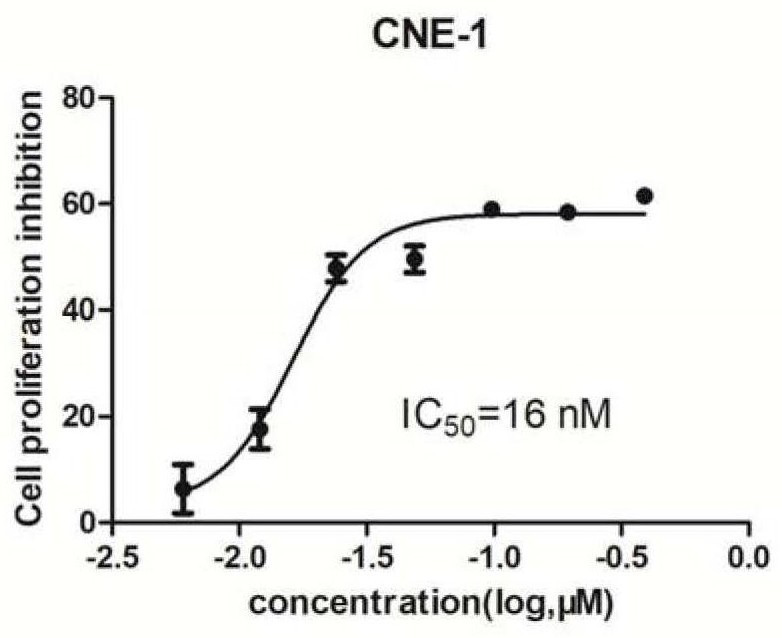

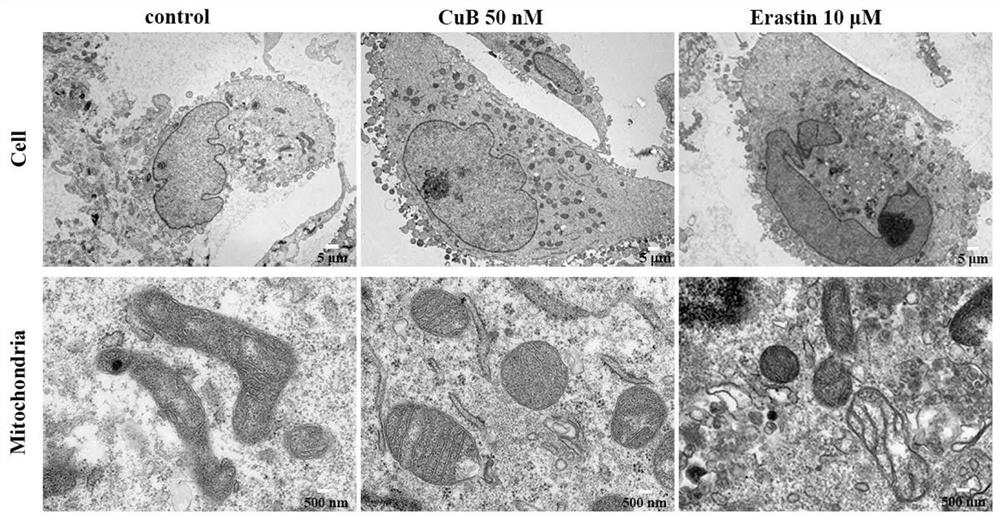

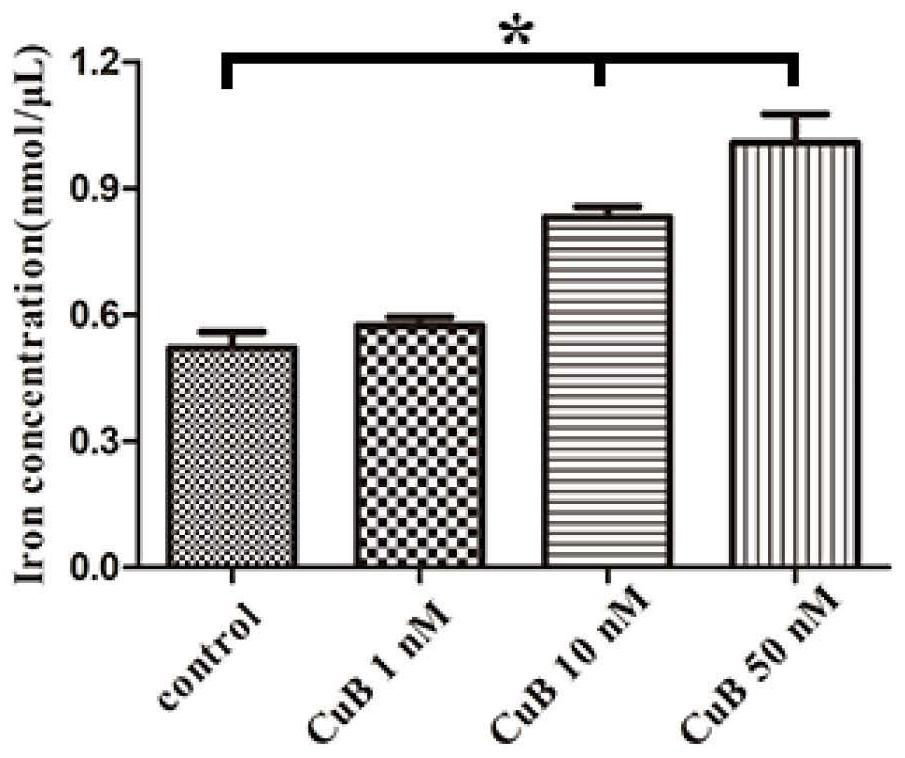

Application of cucurbitacin B in preparation of ferroptosis inducer and anti-nasopharyngeal carcinoma drug

InactiveCN111658655AEffective against nasopharyngeal carcinomaNo side effectsOrganic active ingredientsRespiratory disorderParanasal Sinus CarcinomaSide effect

The invention discloses an application of cucurbitacin B in preparation of a ferroptosis inducer and an anti-nasopharyngeal carcinoma drug. The research shows that cucurbitacin B can induce ferroptosis for the first time; death of nasopharyngeal carcinoma cells is regulated and controlled in a novel cell death promoting mode; and further research finds that cucurbitacin B can promote accumulationof iron ions, reduce the content of glutathione in the cells and down-regulate expression of GPX4 in nasopharyngeal carcinoma cells CNE1, so that lipid peroxide is increased, and iron death of the cells is induced. In in-vitro and in-vivo studies, cucurbitacin B induces the CNE1 cell cycle to be blocked in the G2 / M period and inhibits cell migration and invasion. In addition, cucurbitacin B can significantly inhibit growth of mouse nasopharyngeal carcinoma tumors, and has no obvious toxic or side effect. The invention provides a new choice, namely a ferroptosis inducer, for a medicine for treating nasopharyngeal carcinoma; and meanwhile, a natural novel medicine source, namely cucurbitacin B, is provided for a ferroptosis inducer and treatment of nasopharyngeal carcinoma. The cucurbitacinB is efficient and safe and is free of toxic and side effects.

Owner:THE SECOND AFFILIATED HOSPITAL OF GUANGZHOU MEDICAL UNIV

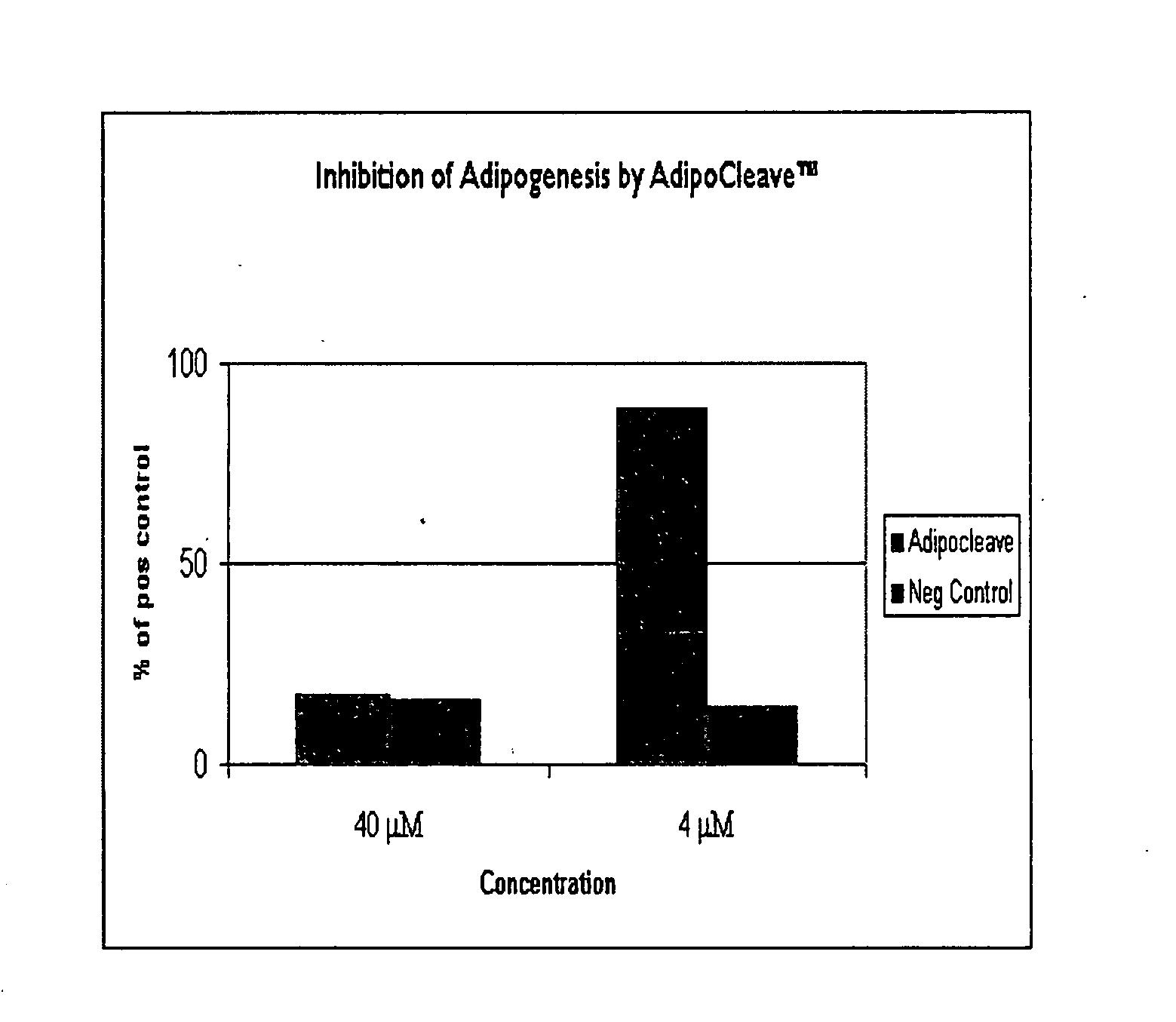

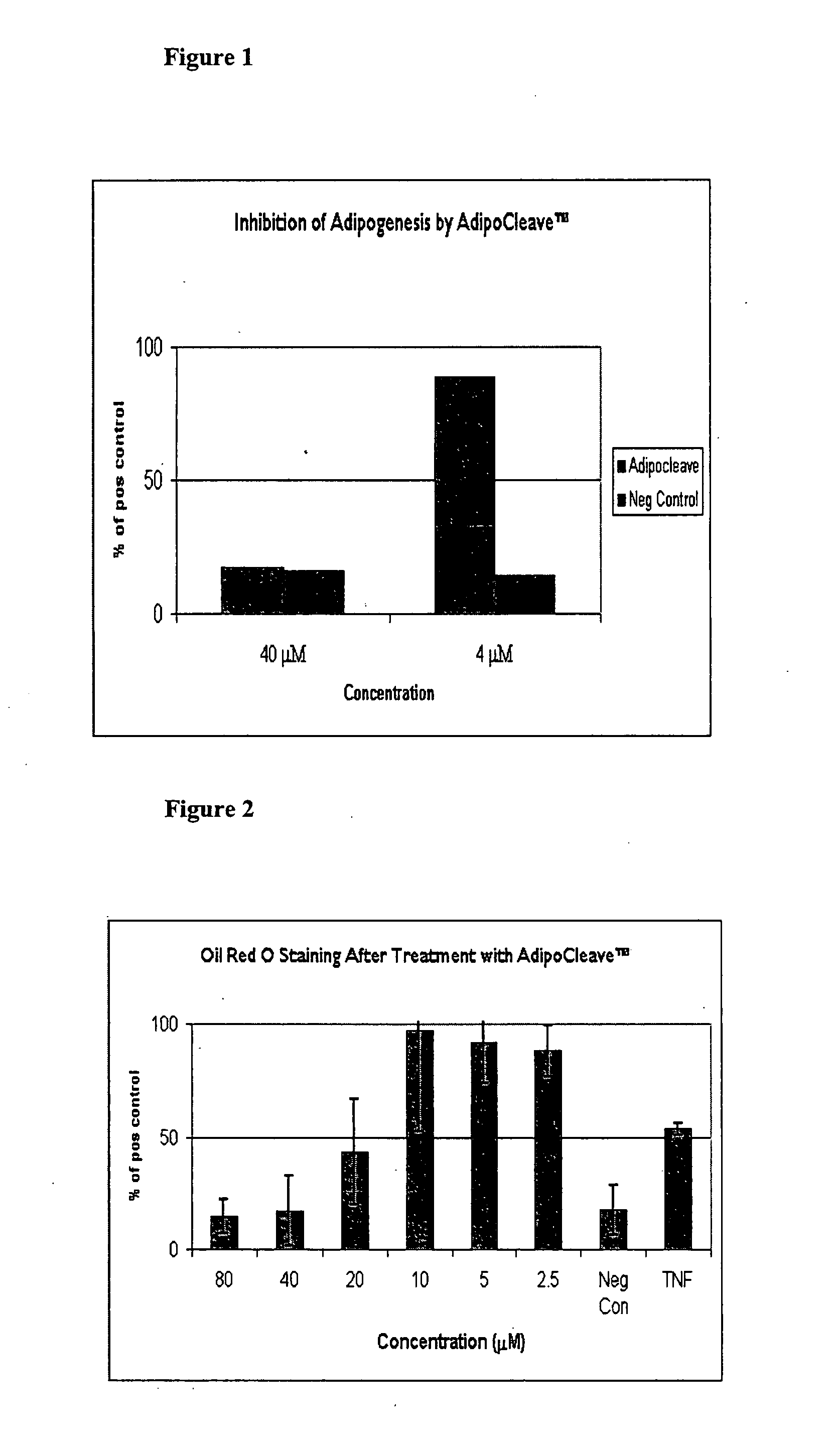

Method and composition for management of weight and blood sugar

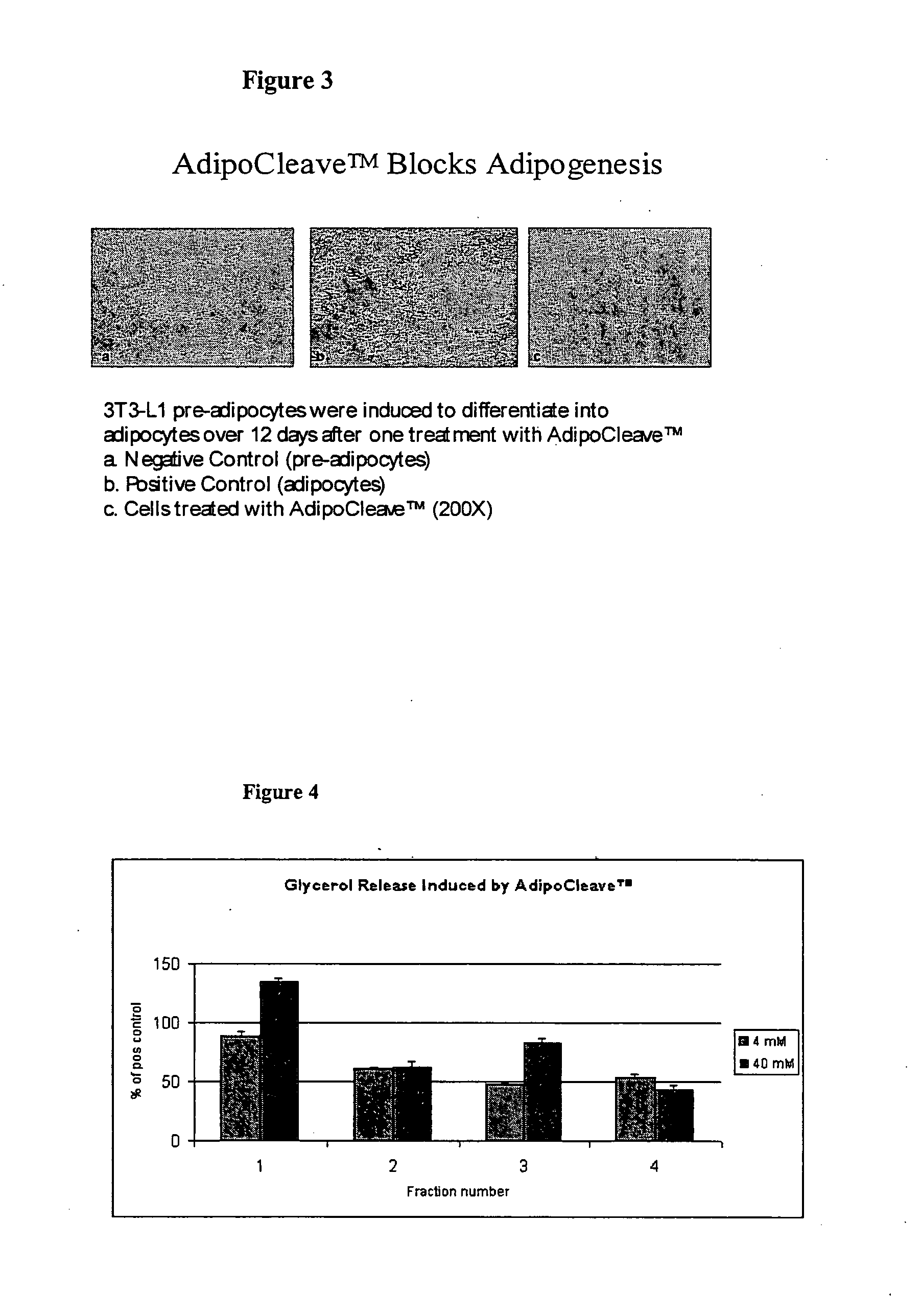

A method for the identification of a composition useful in the treatment of an overweight or obese person to reduce the person's body mass index is provided which comprises obtaining an extract of an ethnobotanical plant, and evaluating the activity of the extract in an assay. A composition is described for treating patient conditions made up of C. grandis standardized extract (AdipoCleave™) with cucurbitacins B and D as active ingredients, Cephalandrol, Cephalandrine A and B, and like compounds and cucurbitacins. The composition is effective to maintain normal blood sugar and normal levels of non-enzymatic protein glycosilation.

Owner:PHYTOMYCO RES CORP

Method of sensitizing cancer cells to the cytotoxic effects of death receptor ligands in cancer treatment

ActiveUS9238069B2Hydroxy compound active ingredientsPeptide/protein ingredientsDeath ReceptorsApoptosis

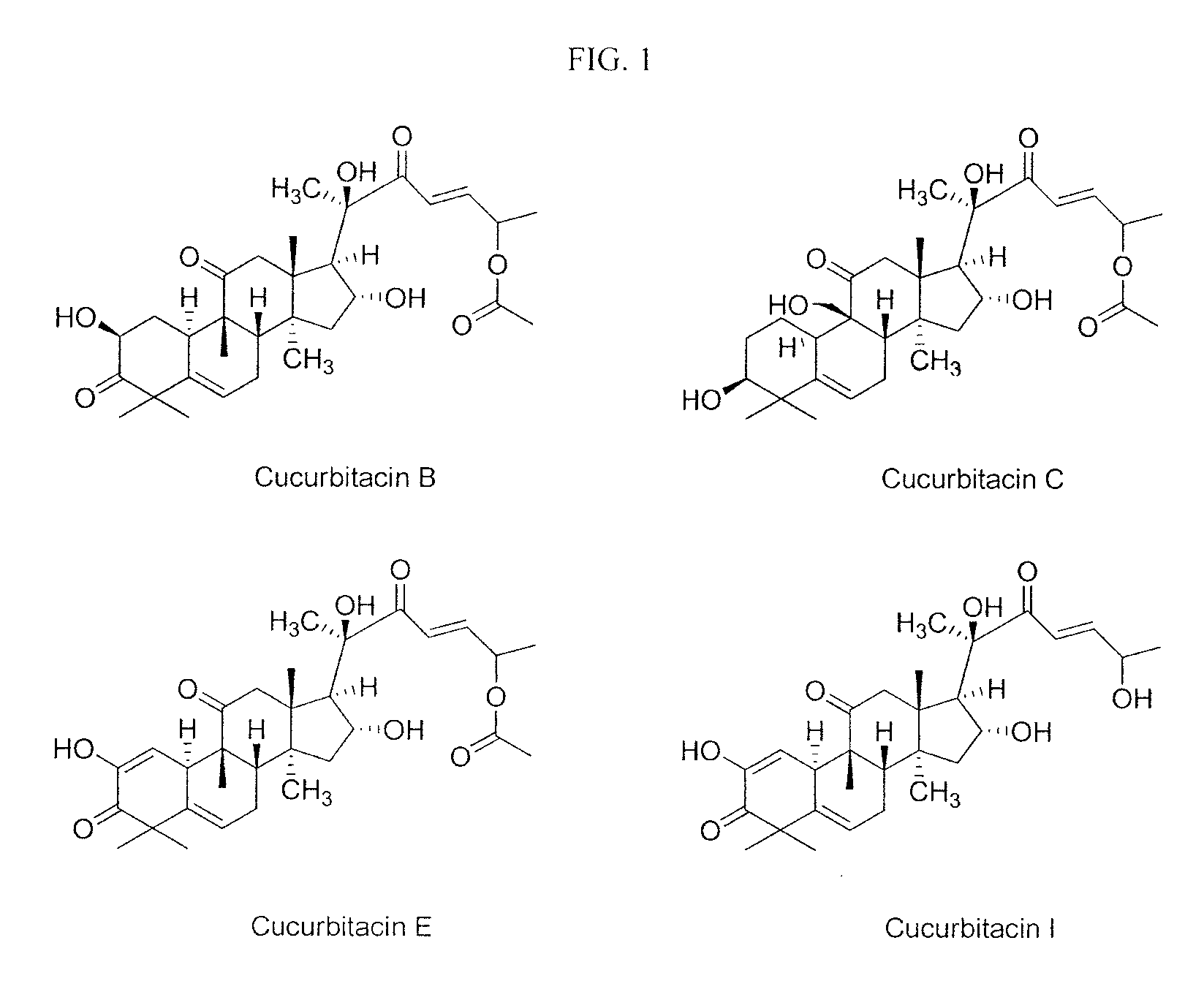

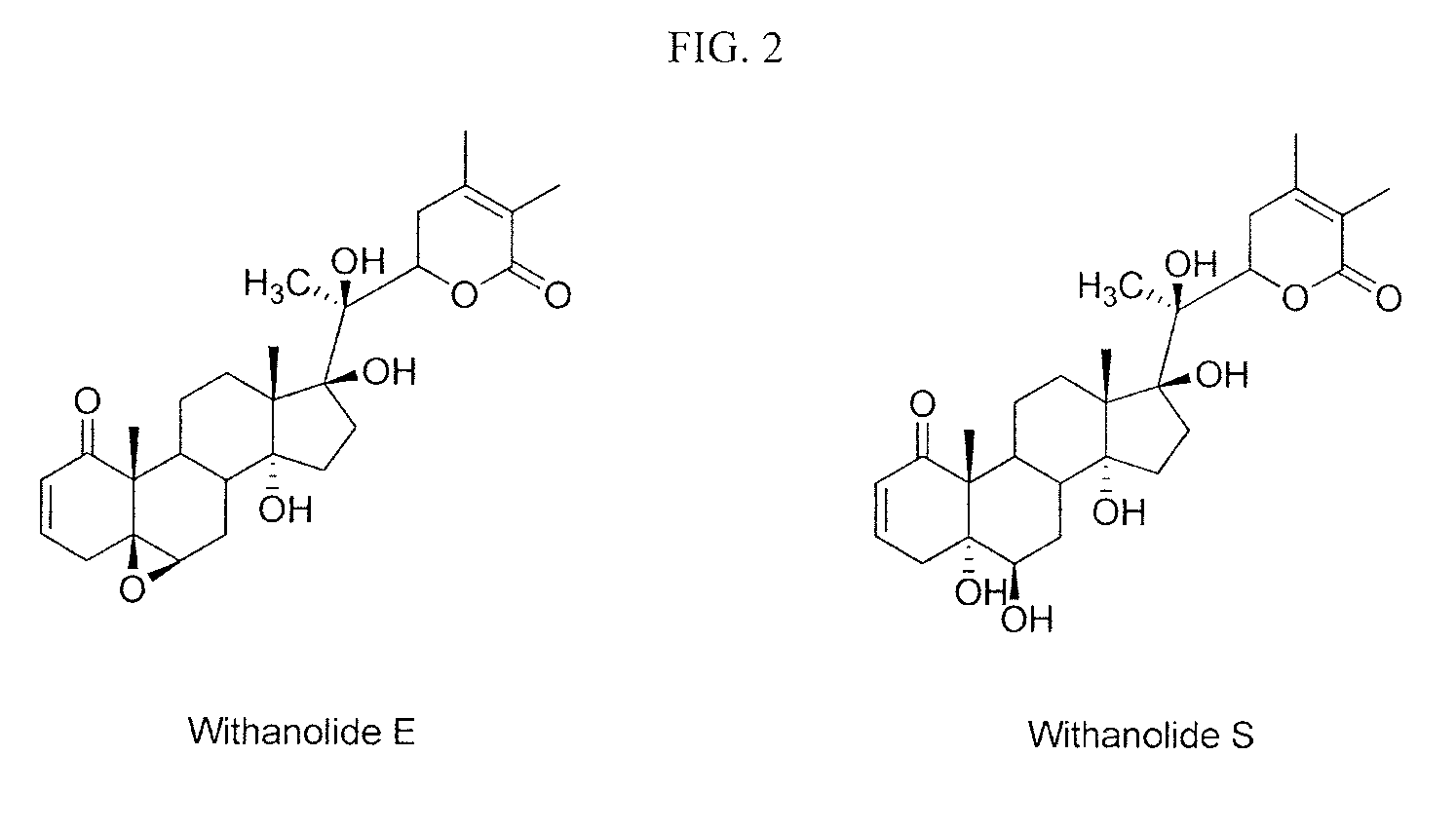

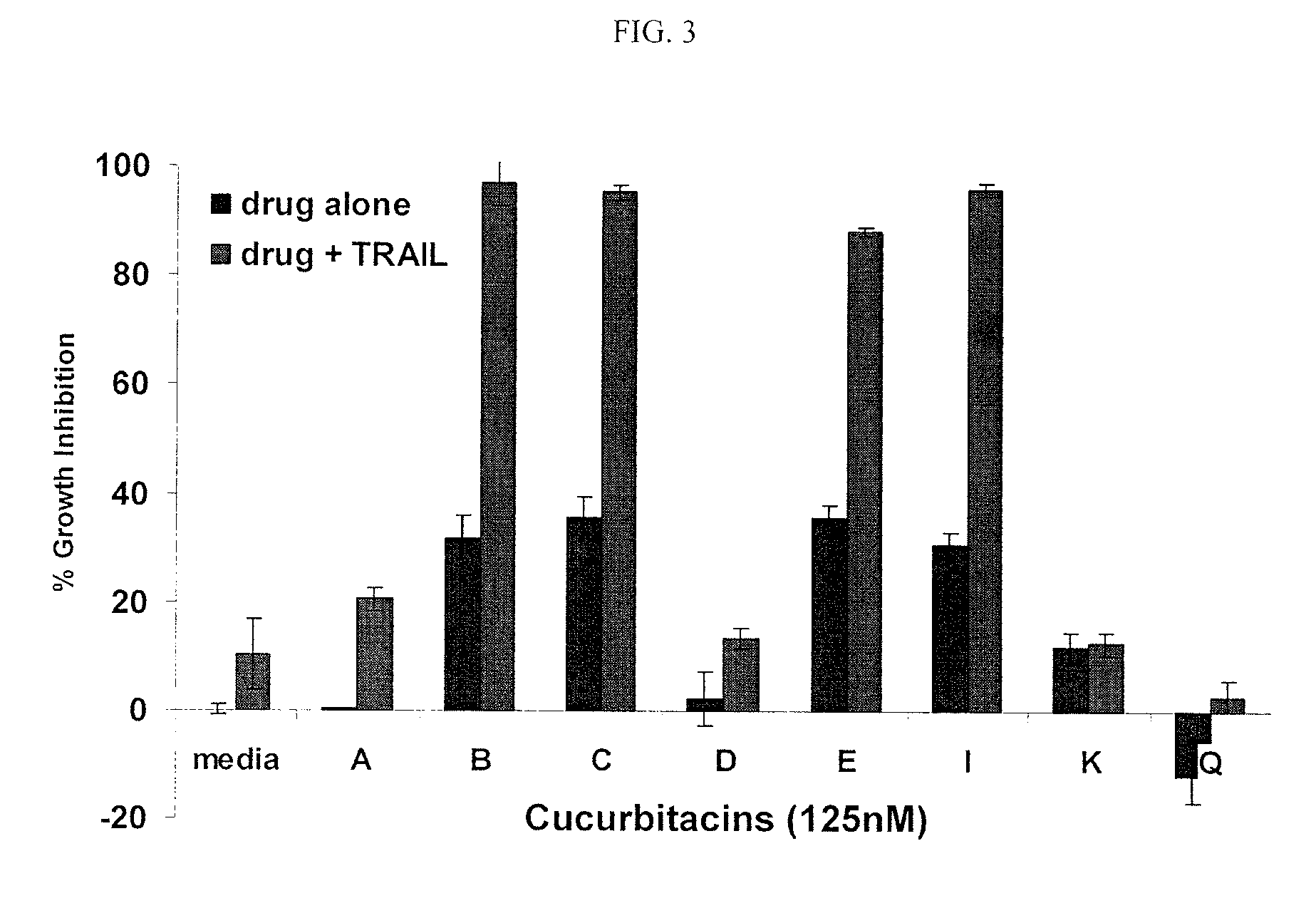

Disclosed is a method of enhancing the response of cancer cells in a mammal to treatment with a death receptor ligand, which method comprises contacting the cancer cells with a death receptor ligand in conjunction with an effective amount of a compound described herein, for example, a cucurbitacin (I) or a withanolide (II). Also disclosed is a method of inducing apoptosis in cancer cells in a mammal, comprising contacting the cancer cells with a compound described herein, for example, a cucurbitacin (I) or a withanolide (II) and also contacting the cancer cells with a death receptor ligand, whereby apoptosis is induced in the cancer cells.

Owner:UNITED STATES OF AMERICA

Cucurbitacins preparation method

InactiveCN104910246AImprove efficiencyHigh puritySteroidsBulk chemical productionPetroleum etherMethanol

The present invention discloses a cucurbitacins preparation method, which comprises: 1) taking a Hemsleya chinensis raw material, crushing, adding to a supercritical CO2 extraction kettle, setting the temperature of 30-50 DEG C and the pressure of 15-25 MPa, introducing liquid-state CO2, concurrently introducing methanol as an entrainer, extracting for 30-150 min, and resolving to obtain an extract, wherein the liquid-state CO2 flow rate is 1-5 ml / min / g of raw material, and the methanol flow rate is 0.1-0.3 ml / min / g; and 2) carrying out hot dissolving on the extract with ethanol, adding an equal volume of petroleum ether, adding a proper amount of an aqueous solution, collecting the petroleum ether layer to recover the reagent, adding an ethanol solution to carry out reflux dissolving, adding active carbon to decolorize, carrying out concentration crystallization on the decolorizing solution, re-crystallizing with an ethanol solution, and drying to obtain the finished product. The cucurbitacins preparation method of the present invention has characteristics of high extraction efficiency, simple purification process, and environmental protection, and is suitable for industrial production.

Owner:NANJING ZELANG AGRI DEV

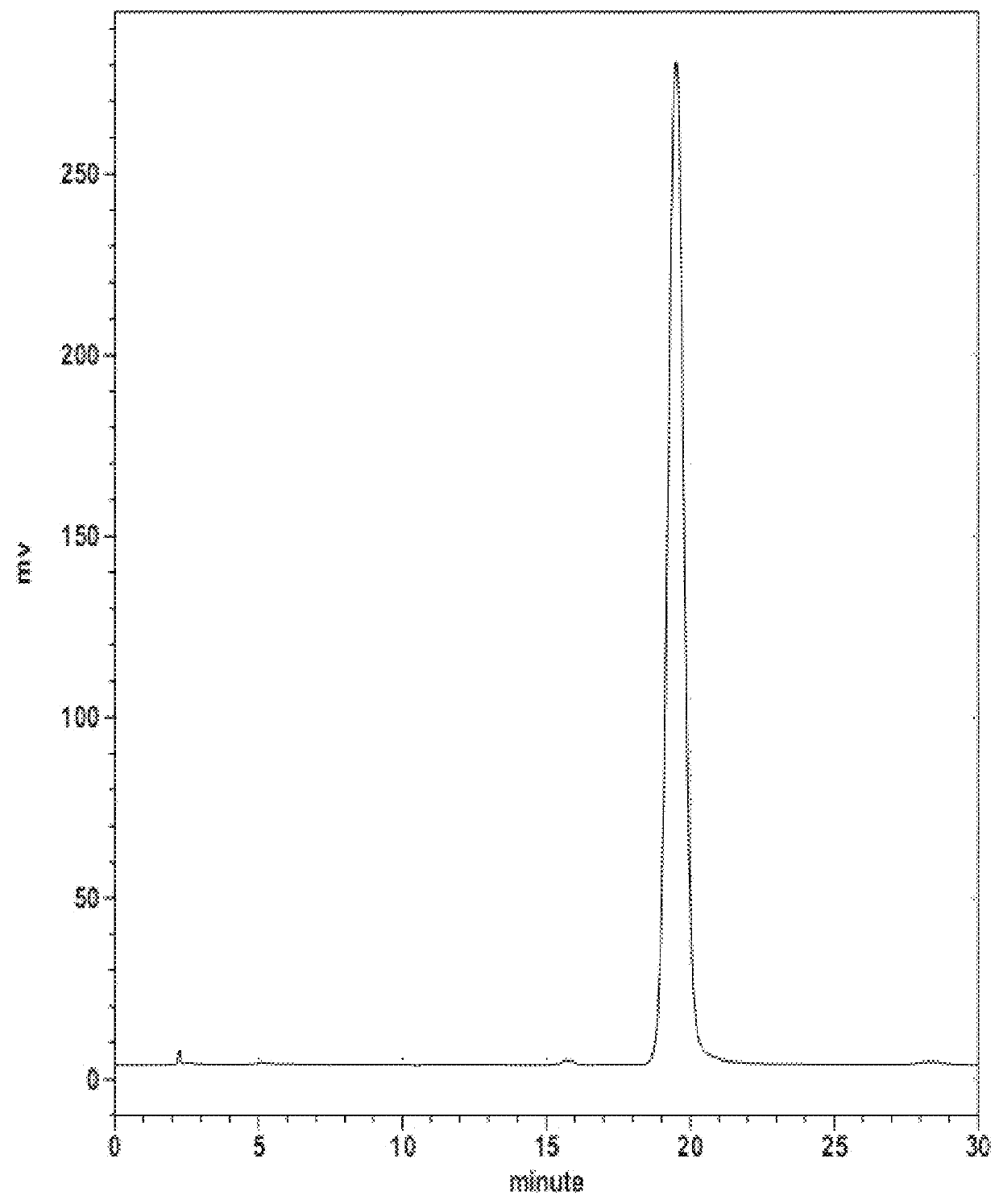

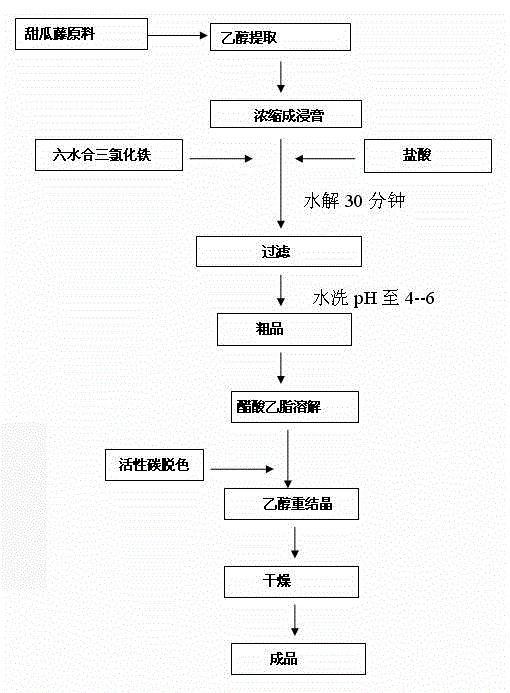

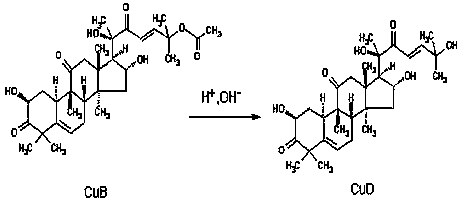

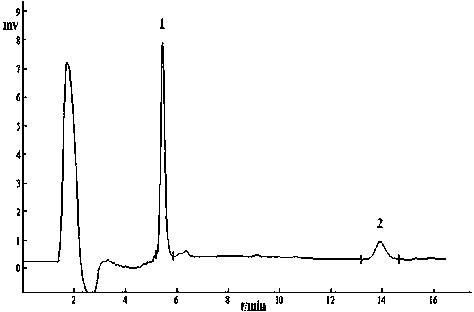

Method for separating cucurbitacin B from muskmelon vine by virtue of catalytic reaction

ActiveCN104086613AReduce manufacturing costGuaranteed maximum utilizationSteroidsActivated carbonWater rinsing

The invention discloses a method for separating cucurbitacin B from muskmelon vines by virtue of catalytic reaction. The method comprises the following steps: an extraction process, namely taking 1 part of the muskmelon vines, soaking by using ethanol, performing reflux extraction, and filtering and concentrating an extracting solution to obtain an extract; the catalytic reaction, namely adding concentrated hydrochloric acid into the extract, then adding ferric trichloride hexahydrate, stirring and reacting, cooling to the room temperature, filtering, performing water rinsing, and drying; a refining process, namely stirring and dissolving a crude product by using ethyl acetate, then adding activated carbon, decoloring, concentrating to a small volume, and standing overnight to perform crystallization; a recrystallization process, namely dissolving a like fine product by using ethanol, filtering and concentrating to a small volume while hot, standing overnight to perform crystallization, and filtering; and putting the fine product in a vacuum drying box, and drying for 8 hours to obtain a cucurbitacin B fine product. The method disclosed by the invention is wide in raw material source and low in production cost, and can be used for reducing the damages of an acid environment to cucurbitacin B; the production rate reaches more than 60%, the purity is more than 99.0%, and the wastewater BOD (biochemical oxygen demand) is less than 100; the method is suitable for the industrial production of recycling water, and can be widely applied to plant extraction industries.

Owner:西安天丰生物科技股份有限公司

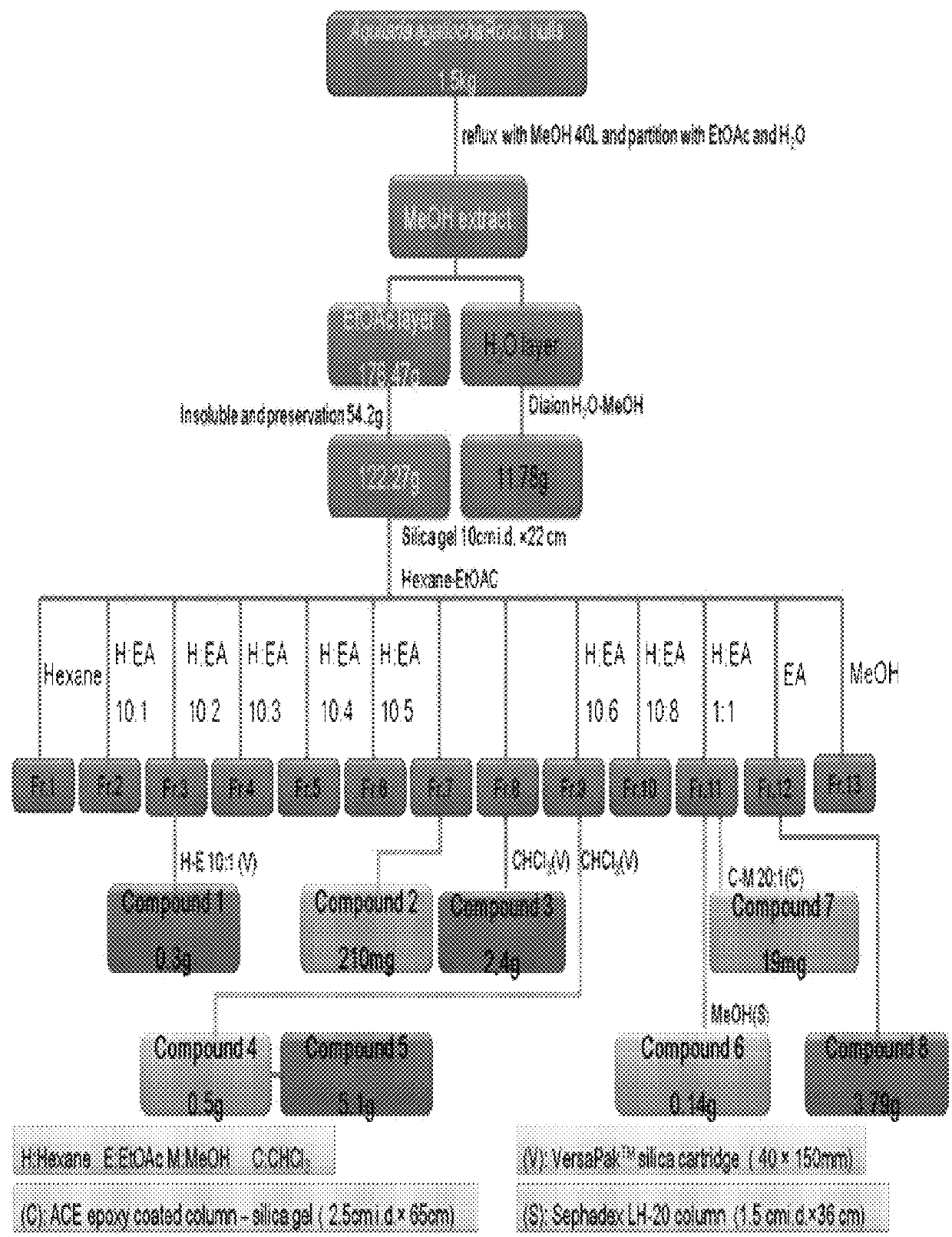

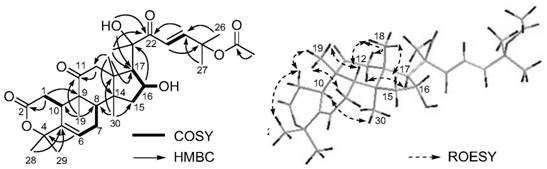

Preparation method and application of chemical components of anti-cancer active part of rosa laevigata flower

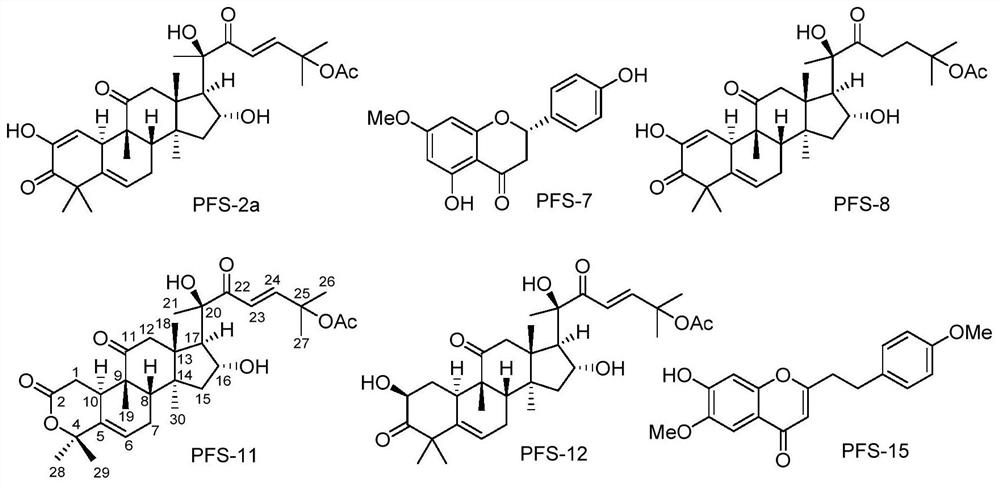

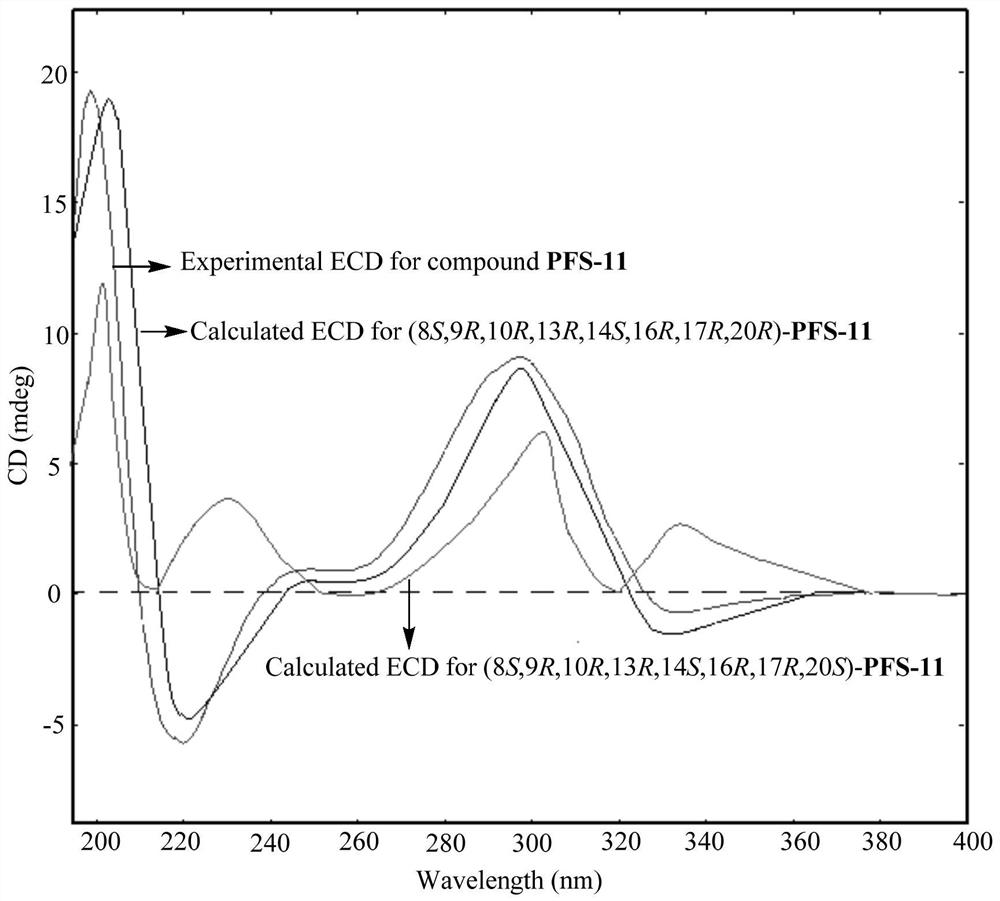

The invention provides an extraction and identification method and application of chemical components in an anti-cancer active site PXS66-2 of rosa laevigata. The invention belongs to the technical field of medicines. According to the method, a separation method of chromatographic column chromatography and semi-preparative high performance liquid chromatography and an identification method of mass spectrum and nuclear magnetic resonance spectrum are adopted for separating and identifying PFS-2a (cucurbitacine E), PFS-7 (sakuranetin), PFS-8 (23, 24-dihydrocucurbitacine E), PFS-12 (cucurbitacine B), PFS-15 (6-methoxy-7-hydroxy-2-[2-(4 '-methoxyphenyl) ethyl]) chromone and a new compound PFS-11 (agilawood lactone A) from PXS66-2. According to the invention, the main chemical components of the PXS66-2 are clarified for the first time, a new compound PFS-11 is separated and identified, and the chemical components can be simply and quickly obtained from the white rosa banksiae flowers and the anticancer active part PXS66-2 of the white rosa banksiae flowers and the anticancer active part PXS66-2 of the white rosa banksiae flowers through the method disclosed by the invention, and can be used for establishing quality control standards of the white rosa banksiae flowers and the anticancer active part PXS66-2 of the white rosa banksiae flowers.

Owner:KUNMING INST OF BOTANY - CHINESE ACAD OF SCI +1

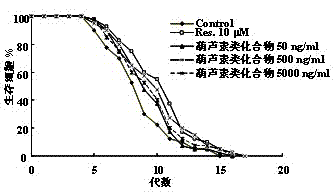

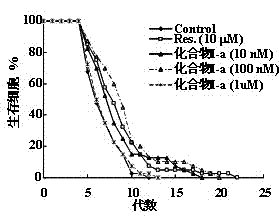

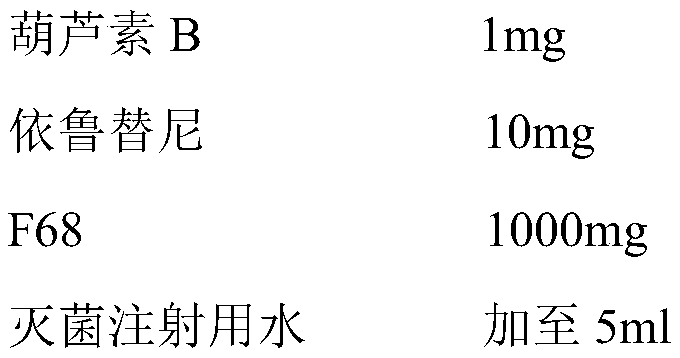

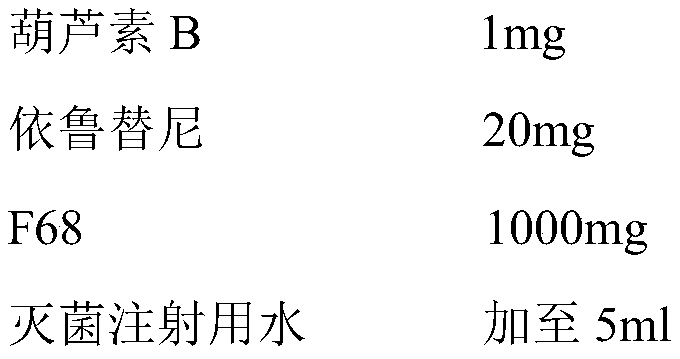

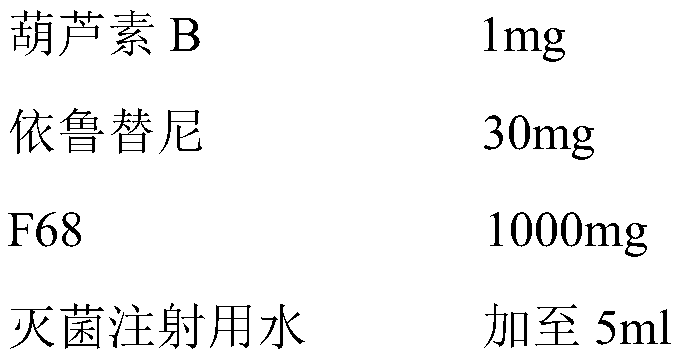

Cucurbitacine and ibrutinib composite for treating breast cancer

ActiveCN111419853AGood synergistic effectGrowth inhibitionOrganic active ingredientsSexual disorderPharmaceutical drugCurative effect

The invention relates to a medicine composite for treating breast cancer, particularly triple negative breast cancer. The composite comprises cucurbitacine and ibrutinib. The invention further relatesto a use of the combination of the cucurbitacine and the ibrutinib in the preparation of medicines for treating triple negative breast cancer. The combination of the cucurbitacine and the ibrutinib has a significant synergistic curative effect in the treatment of breast cancer, especially triple negative breast cancer. The composite brings new hope for breast cancer patients, provides scientificbasis for research and development of novel antitumor medicines, and has a promising application prospect.

Owner:DELI WEI BEIJING BIOLOGICAL TECH

A kind of method extracting starch and cucurbitacin from Luo Han Guo tuber root

InactiveCN102690359BAvoid dependenceReduce manufacturing costSteroidsSiraitia grosvenoriiCrystallization

Owner:HUNAN AGRICULTURAL UNIV

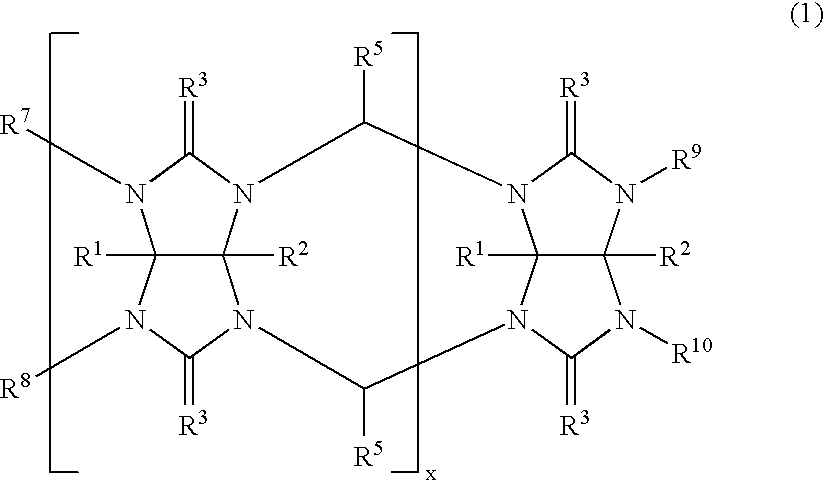

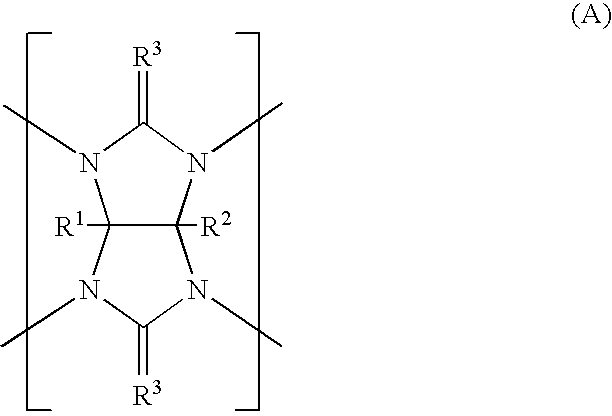

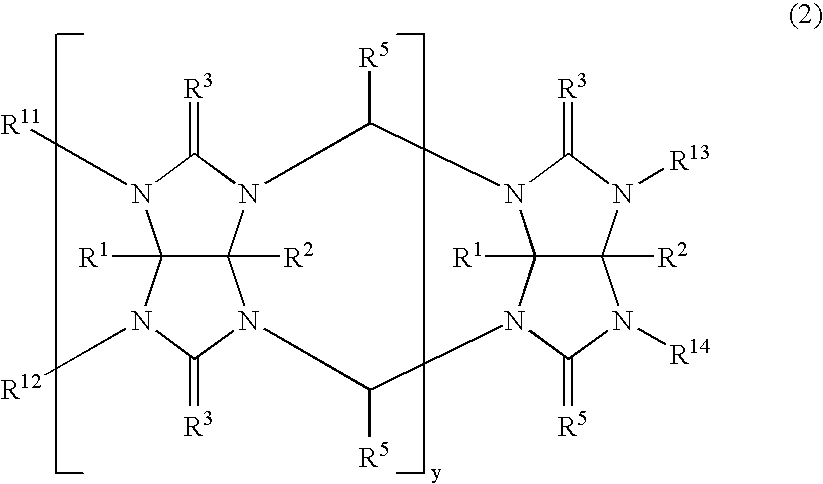

Method for preparing cucurbiturils

The invention relates to a method for preparing cucurbiturils. The method comprises reacting an oligomer consisting of 2 to 11 linked glycolurils or glycoluril analogues with one or more compounds selected from glycoluril, glycoluril analogues and / or oligomers of glycoluril or glycoluril analogues, in the presence of an acid, to form a cucurbituril. The method can be used to prepare variably substituted cucurbiturils having specific substituted units at specific locations in the cucurbituril. The invention also provides cucurbiturils prepared by the method of the invention. The invention further provides novel cucurbiturils.

Owner:ANTHONY IVAN DAY

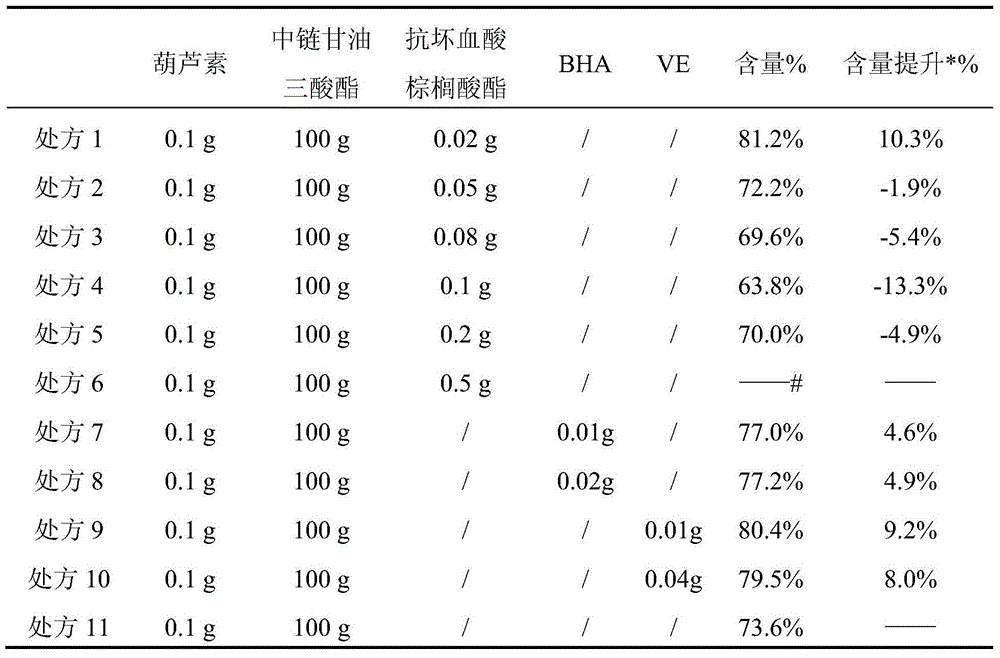

Pharmaceutical composition containing cucurbitacine and preparation method thereof

The invention provides a steady composition containing cucurbitacine. The composition provided by the invention contains cucurbitacine, an oil solvent and a stabilizing agent, wherein the stabilizing agent is ascorbyl palmitate or a mixture of ascorbyl palmitate and vitamin E. The composition provided by the invention has high bioavailability; and in addition, the stability of cucurbitacine preparations can be obviously increased.

Owner:DELI WEI BEIJING BIOLOGICAL TECH

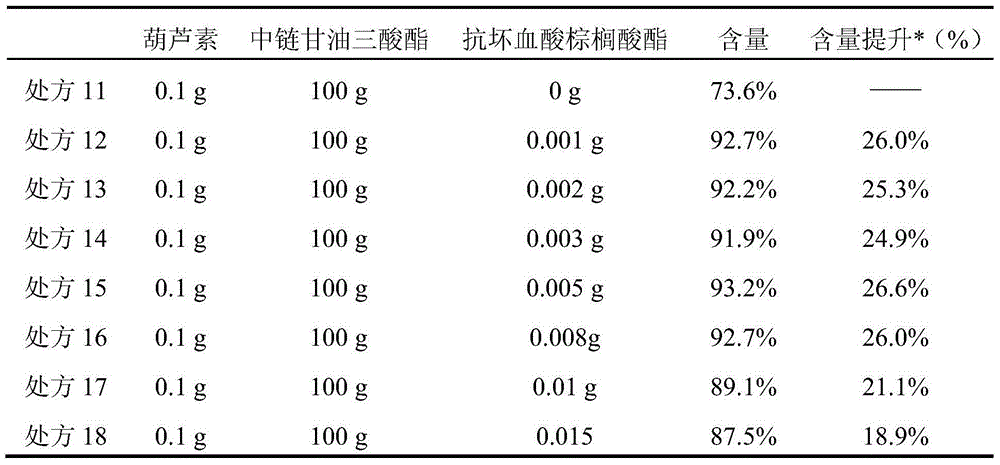

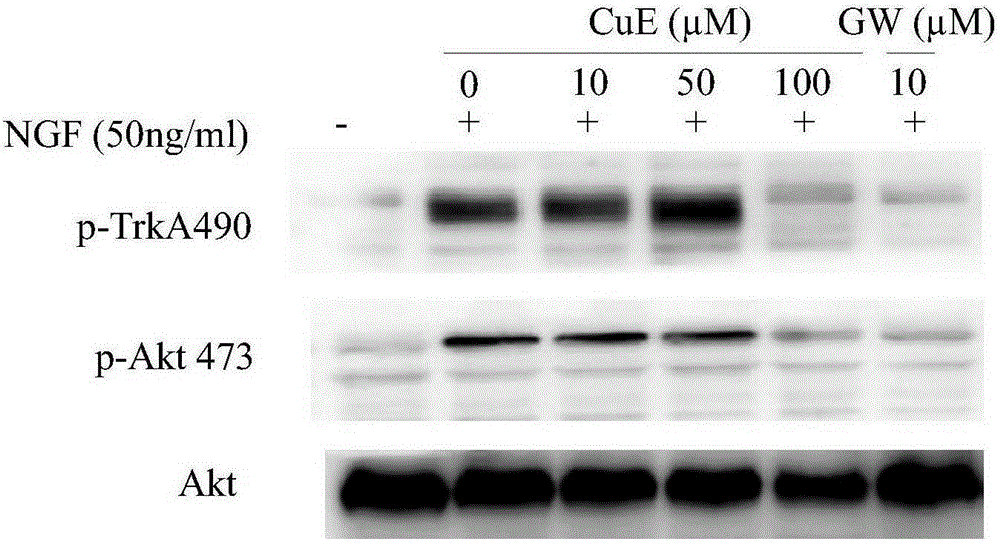

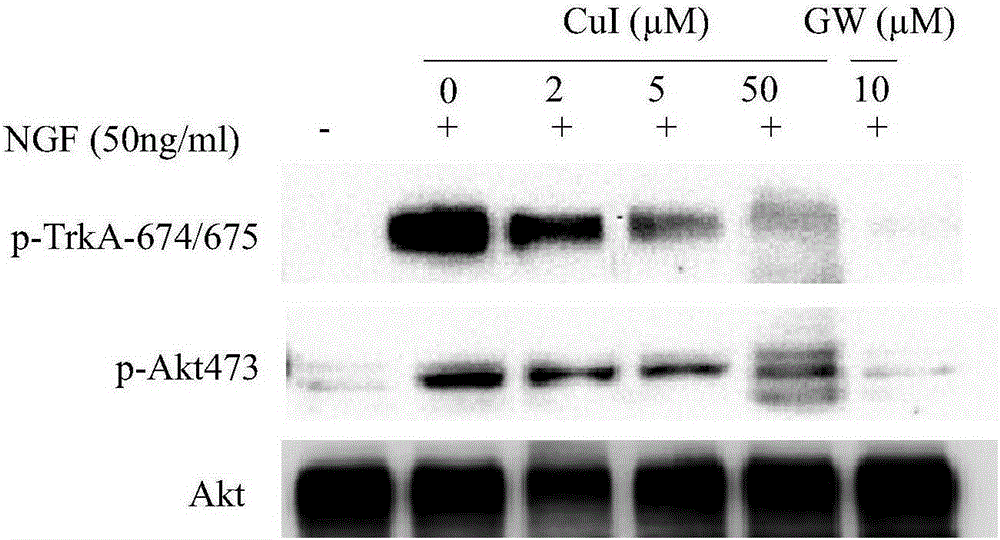

Application of cucurbitacine in preparing TrkA kinase inhibitor medicines

InactiveCN105520945AInhibits TrkA phosphorylationGood treatment effectOrganic active ingredientsNervous disorderMedicineAtopic dermatitis

The invention provides an application of cucurbitacine or a derivative thereof in preparing TrkA kinase inhibitor medicines. The research shows that cucurbitacine can effectively inhibit TrkA kinase, can have good treatment or improvement effect on skin itch, atopic dermatitis, psoriasis and neuropathic pain, and thus a novel choice is provided for clinical medication.

Owner:CHENGDU MEDICAL COLLEGE

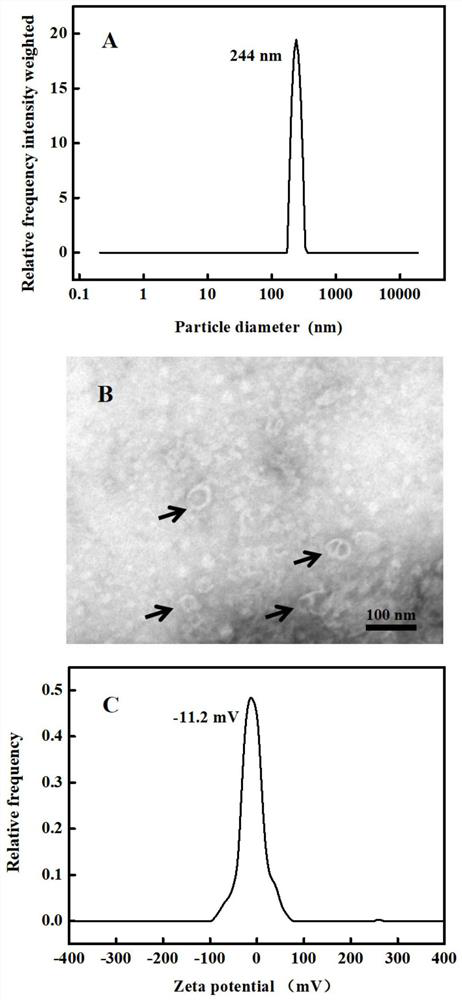

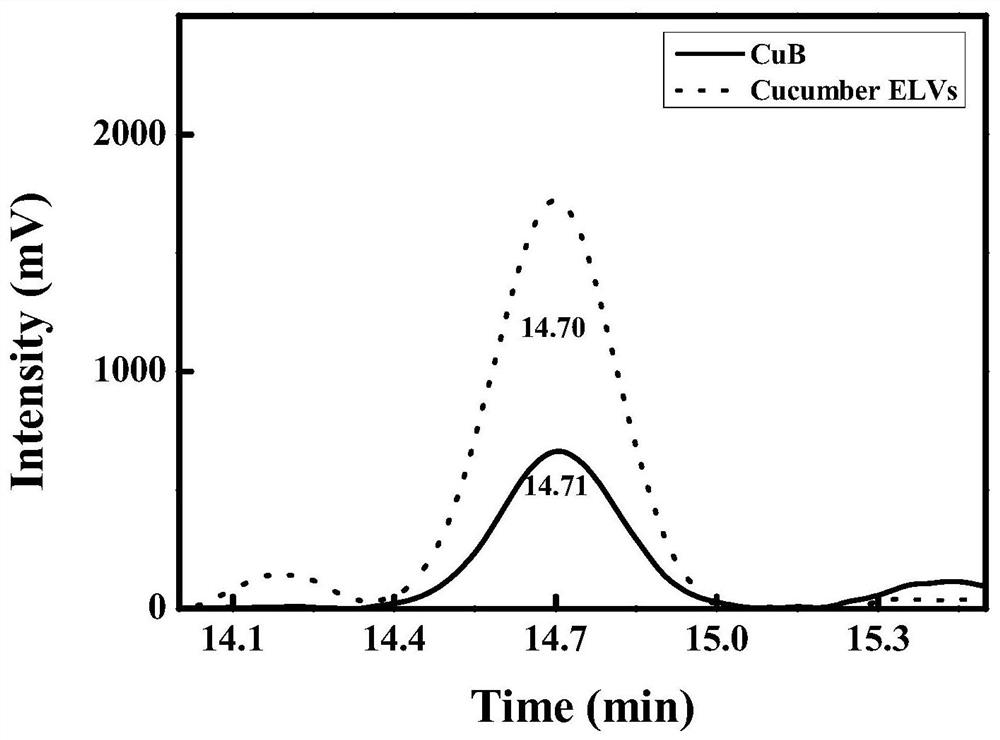

Cucumber exosome-like vesicles containing cucurbitacin B and capable of being used as anti-cancer drugs

ActiveCN112472731AGuaranteed stabilityInhibitory activityOrganic active ingredientsAntineoplastic agentsCancer cellTumor therapy

Owner:FUJIAN MEDICAL UNIV

Method for preparing cucurbitacine D by hydrolyzing cucurbitacine B

The invention discloses a method for preparing cucurbitacine D by hydrolyzing cucurbitacine B. The method is simple and easy to implement, and only comprises the steps of (1) dissolving the cucurbitacine B in a good solvent to obtain an organic phase, (2) preparing an alkali liquor having a pH value greater than 9 and / or a buffer solution to obtain a water phase, (3) adding the water phase to the organic phase, and stirring evenly to obtain a reaction solution proportioned in the organic phase and the water phase, (4) reacting the reaction solution at a temperature above 20 DEG C, and then stopping reacting in an ice bath, and (5) adding an isometric ethyl acetate extraction hydrolysis product to the reaction solution in which the reaction is stopped, and carrying out rotary evaporation at 40 DEG C so that the ethyl acetate volatilizes, thus obtaining the desired hydrolysis product. The method solves the problem of single source of the cucurbitacine D.

Owner:SHENYANG PHARMA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com