Method for separating cucurbitacin B from muskmelon vine by virtue of catalytic reaction

A catalytic reaction, melon vine technology, applied in the fields of organic chemistry, steroids, etc., can solve the problems of inability to provide tons of raw materials, hidden dangers of fermentation tank and site safety, undesired industrial products, etc. The effect of short time and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

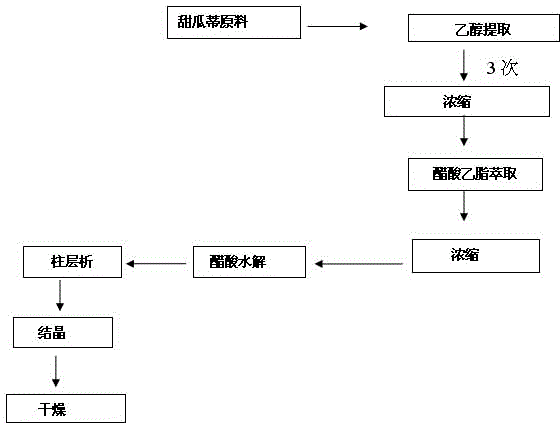

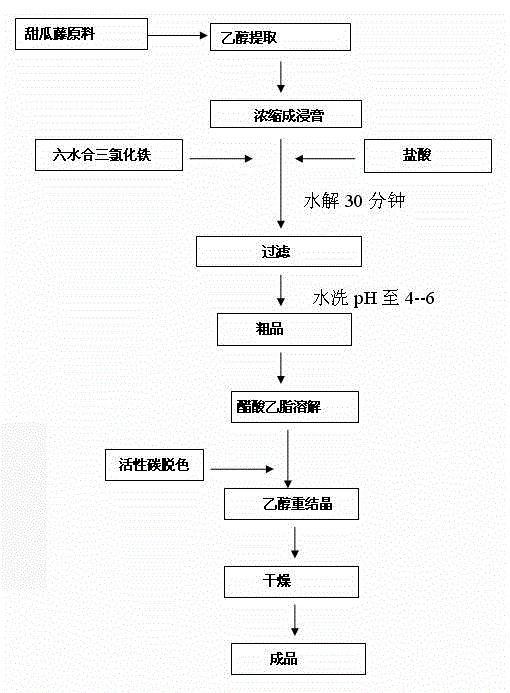

Method used

Image

Examples

Embodiment 1

[0088] Get 1.5 kilograms of raw materials, add 9 liters of ethanol, heat and extract three times in a 20L wide-mouthed bottle, each time for 1 hour, concentrate to obtain 163 grams of extract, detect that the concentration of cucurbitacin B is 18.4 mg / g, 163 grams of extract, add 24.45 1 gram of concentrated hydrochloric acid, then add 4.89 gram of ferric chloride hexahydrate, react for 30 minutes, the pH after washing is 4~6, obtain 78 gram of crude product, detect that the content of cucurbitacin B is 61.5 mg / gram, the yield of cucurbitacin B increases It was 59.94%, and carried out crystallization and suction filtration according to the invention process. Obtain product 3.53 grams, content detection is 98.33%.

Embodiment 2

[0090] Get 15 kilograms of raw materials, add 90 liters of ethanol, heat and extract three times in a 200L extraction tank, each time for 1 hour, concentrate to obtain 1576 grams of extract, detect that the concentration of cucurbitacin B is 17.95 mg / g, 1576 grams of extract, add 236.4 gram of concentrated hydrochloric acid, then add 47.28 grams of ferric chloride hexahydrate, react for 30 minutes, wash pH4-6 to obtain 791 grams of crude product, detect that the content of cucurbitacin B is 56.83 mg / gram, and the yield of cucurbitacin B increases to 58.9%. And carry out crystallization and suction filtration according to the inventive process. 36.7 g of product was obtained.

[0091] The content detection is 99.13%.

Embodiment 3

[0093] Get 50 kilograms of raw materials, add 300 liters of ethanol, heat and extract three times in the extraction tank of 500L, each time 1 hour, concentrate and obtain 4961 grams of extract, detect that the concentration of cucurbitacin B is 17.64 mg / g, 4961 grams of extract, add 744.15 1 gram of concentrated hydrochloric acid, then add 148.83 gram of ferric chloride hexahydrate, react for 30 minutes, wash pH4-6 to obtain 2473 gram of crude product, detect that the content of cucurbitacin B is 55.72 mg / gram, and the yield of cucurbitacin B increases to 57.46%. And carry out crystallization and suction filtration according to the inventive process. Obtain product 121.7 grams,

[0094] The content detection is 98.81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com