Energy-saving high-pressure water electrolysis hydrogen production tank

A water electrolysis and electrolytic cell technology, which is applied in the electrolysis process, electrolytic components, electrode shape/type, etc., can solve the problems of large sealing surface width, high density, and increased maintenance cost of electrolytic cells, and avoid hot-tight assembly process, The effect of large effective surface area and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

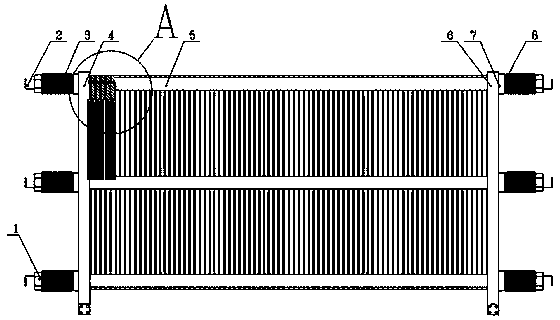

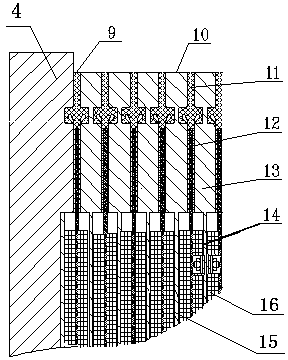

[0046] This embodiment provides an energy-saving high-pressure water electrolysis hydrogen production electrolyzer, which combines figure 1 with figure 2 , Including a flat cylindrical positive terminal plate 6 and a negative terminal plate 4 located at opposite ends, respectively. The positive terminal plate 6 and the negative terminal plate 4 are alternately arranged with flat cylindrical combined sealing gaskets 9 and poles. The plate frame assembly 10 is kept parallel. The screw 2 passes through the positive terminal plate 6 and the negative terminal plate 4 to fasten the combined sealing gasket 9 and the polar plate frame assembly 10. The two cylindrical end faces of the combined sealing gasket 9 are respectively provided A circular sealing lip sealing lip 20 eccentric to the center of the circle, a circular high-pressure sealing groove 21 is respectively provided on the two cylindrical end faces of the electrode plate frame assembly 10, and the sealing lip 20 of the combin...

Embodiment 2

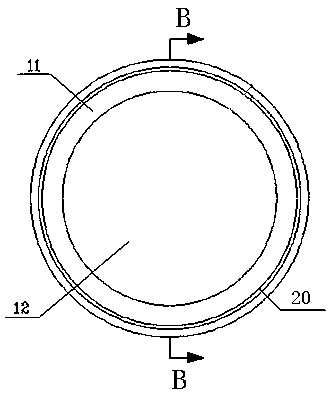

[0052] The combined seal 9 is composed of a ring-shaped rubber gasket 11 and a circular diaphragm asbestos cloth 12 located in the ring. The edge of the diaphragm asbestos cloth 12 and the inner edge of the rubber gasket 11 are integrated by a vulcanization hot pressing process The rubber gasket 11 is EPDM rubber, the diaphragm asbestos cloth 12 is a densely woven twill asbestos cloth specially used for water electrolysis hydrogen production, and the combination of the rubber gasket 11 and the diaphragm asbestos cloth 12 is the rubber gasket 11. When vulcanizing and compacting, place the outer ring of the diaphragm asbestos cloth 12 on the inner side of the rubber gasket 11, and simultaneously compress and vulcanize to ensure that the rubber gasket 11 and the diaphragm asbestos cloth 12 adhere firmly, and the length of the bonding part is 20-80mm.

[0053] A ring of sealing lips 20 biased toward the center of the rubber sealing gasket 11 is respectively provided on both ends of th...

Embodiment 3

[0058] Combine Image 6 , Figure 7 with Picture 9 , The pole plate frame assembly 10 is formed by welding a ring-shaped pole plate frame 13 and a circular pole plate assembly 14 located in the ring. The two ends of the pole plate frame 13 are provided with a seal lip 20 at the position corresponding to the sealing lip 20. Ring high-pressure sealing groove 21, the sealing lip 20 is embedded in the high-pressure sealing groove 21 with a movable gap; the opposite inner surfaces of the positive terminal plate 6 and the negative terminal plate 4 are also respectively provided with a ring for embedded sealing The high-pressure sealing groove 21 of the lip 20.

[0059] The outer diameter of the high-pressure sealing groove 21 is the same as the outer diameter of the sealing lip 20 on the rubber gasket 11, and the diameter is determined according to the designed electrolytic cell gas output. The depth of the high-pressure sealing groove 21 is 4-20mm and the width is 8-30mm. The width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com