Radio frequency and band-shaped wire interface assembly method

An assembly method and stripline technology, applied in electrical components, circuits, waveguide-type devices, etc., can solve problems such as the inability to know the theoretical and physical design methods, the design of high-speed signal interfaces, and the lack of complete design methods. , to achieve the effect of reducing space volume and design difficulty, fast signal transmission, and reducing the space required for wiring and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

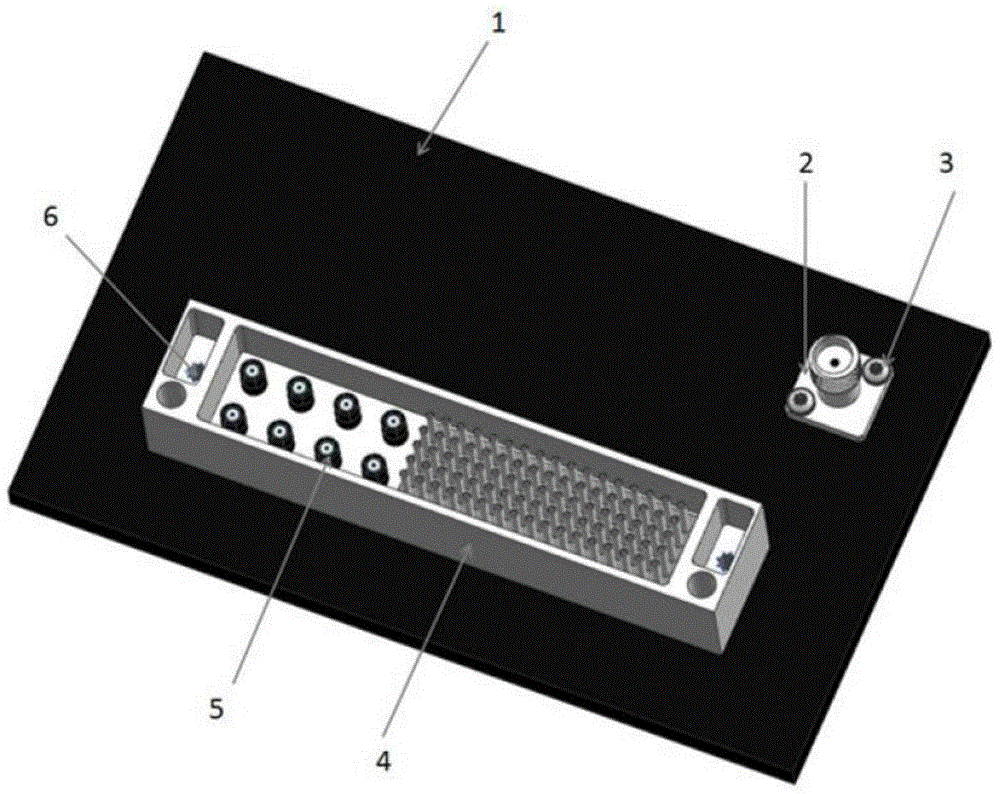

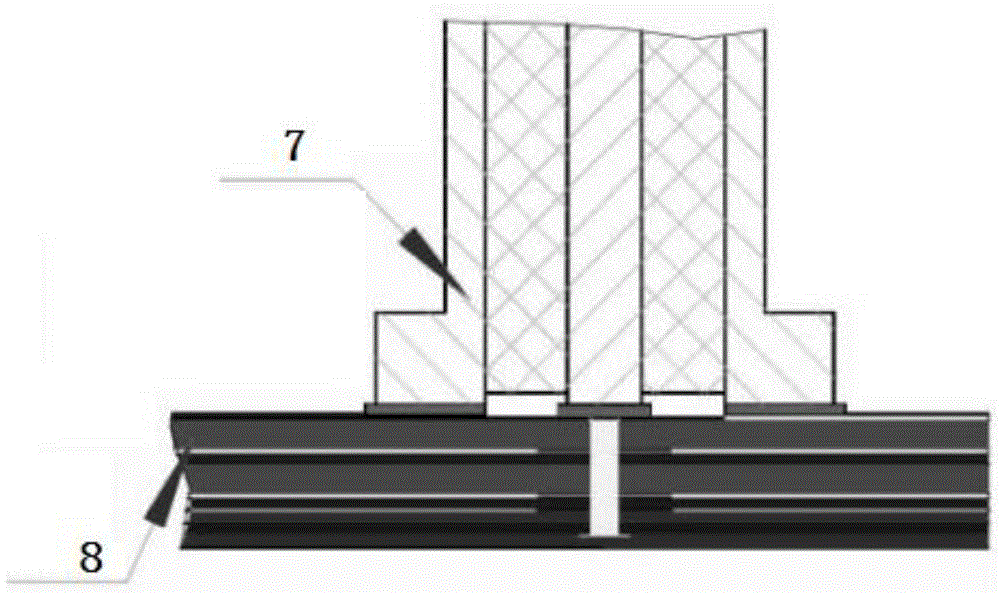

[0024] refer to Figure 1-Figure 3 . In a best implementation case described below, the broadband microwave backplane operating in the 6GHz frequency range, the assembly structure of the RF connector on the broadband microwave backplane mainly includes the broadband microwave backplane, connected through strip lines and metalized holes Arrayed high-frequency connectors 5, independent high-frequency connectors 2 and low-frequency connectors 4 together. The broadband microwave backplane serving as the high-frequency connector bearing layer and high-frequency interconnection is provided with soldering pads for connector welding. Large-area metal ground and metal transmission lines are all copper layers. The weldable areas on the upper and lower surfaces of the broadband microwave backplane are interconnected with the internal striplines of the broadband microwave backplane through metallized holes. Solder paste is used to realize the brazing assembly of the high-frequency sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com