Slow-release fertilizer coating material containing terephthalic polyester polyol and preparation process thereof

A coating material and preparation process technology, applied in fertilizer mixtures, fertilization devices, agriculture, etc., can solve problems such as shortening production time, restricting use, and filming interruption, reducing equipment investment costs, avoiding waste, and fertilizer utilization. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

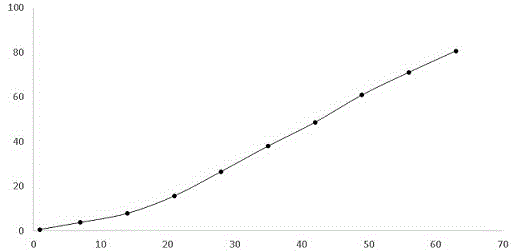

Image

Examples

Embodiment 1

[0031] Preparation of coated slow-release fertilizer: Heat 1 ton of granular urea with a particle size of 2mm-4mm to 58-65°C in a coating machine, pump 14.1kg of p-phenylene polyester polyol and 11.5kg of crude MDI into the coating machine at the same time On the surface of the moving granular fertilizer, the input amount of the coating material is 0.7~1wt% of the total weight of the granular fertilizer, and it is solidified for 4~6 minutes; repeat the above coating step 3 times until the coating material accounts for 2.5% of the total weight of the core fertilizer. %, adding 0.2%-0.5% paraffin wax to the total mass of the fertilizer, cooling to 20-30°C to prepare a coated slow-release fertilizer.

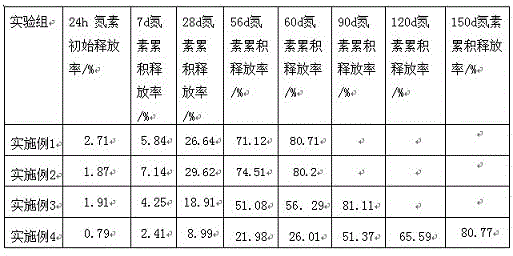

[0032] Slow and controlled release performance test of coated slow and controlled release fertilizer: Under the condition of 25°C, the nutrient release period of the coated slow and controlled release fertilizer was tested by static water extraction method, and the number of days ...

Embodiment 2

[0036] Preparation of coated slow-release fertilizer: Heat 1 ton of granular urea with a particle size of 2mm-4mm to 58-65°C in a coating machine, mix 11.2kg of p-phenylene polyester polyol with 2.9kg of castor oil Simultaneously pump 11.5kg of coarse MDI into the surface of the constantly moving granular fertilizer, the input amount of the coating material is 0.7-1wt% of the total weight of the granular fertilizer, and solidify for 4-6 minutes; repeat the above coating step 3 times until the coating The coating material accounts for 2.5% of the total amount of the core fertilizer, and 0.2%-0.5% of the total mass of the fertilizer is added with paraffin wax, and cooled to 20-30°C to obtain a coated slow-release fertilizer.

[0037] Slow and controlled release performance test of coated slow and controlled release fertilizer: Under the condition of 25°C, the nutrient release period of the coated slow and controlled release fertilizer was tested by static water extraction meth...

Embodiment 3

[0041] Preparation of coated slow-release fertilizer: heat 1 ton of granular urea with a particle size of 2mm-4mm to 58-65°C in a coating machine, and pump 19.2kg of p-phenylene polyester polyol and 13.9kg of crude MDI into the coating machine at the same time On the surface of the constantly moving granular fertilizer, the input amount of the coating material each time is 0.7-1wt% of the total weight of the granular fertilizer, and solidified for 4-6 minutes; repeat the above coating step 3-5 times until the coating material accounts for the total weight of the core fertilizer. 3.2% of the total mass of the fertilizer, adding 0.2%-0.5% paraffin of the total mass of the fertilizer, cooling to 20-30°C to obtain a coated slow-release fertilizer.

[0042] Slow and controlled release performance test of coated slow and controlled release fertilizer: Under the condition of 25°C, the nutrient release period of the coated slow and controlled release fertilizer was tested by st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com