Preparation device and application of a dual-function slow-release nitrogen fertilizer

A preparation device and dual-function technology, which is applied in the direction of fertilization device, application, fertilizer mixture, etc., can solve the problems of easy water absorption and disintegration fertilizer efficiency, uneven distribution of components, safety and pollution, etc., achieve wide development and application prospects, increase additional Value, the effect of long release period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation device for dual-function slow-release nitrogen fertilizer, comprising:

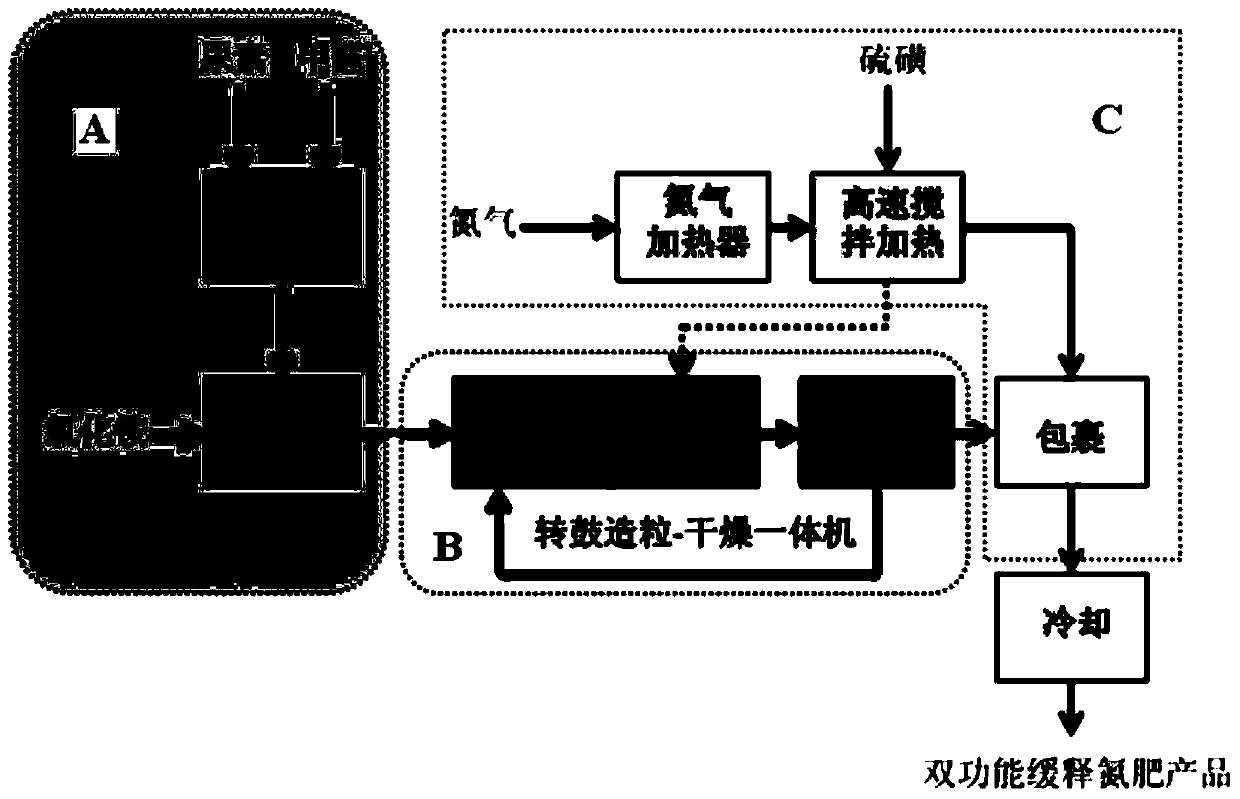

[0042] Material pretreatment component A: including urea-formaldehyde heating polymerization parts and ammonium chloride-urea-formaldehyde heating mixing parts composed of pipelines in series;

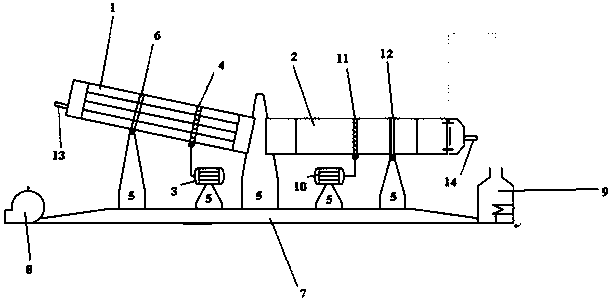

[0043] Drum granulation-drying integrated machine component B, its structure is as follows figure 2 Shown: It includes the induced draft fan, the drum granulation cylinder, the rotary drying cylinder and the hot blast stove which are arranged on the base and connected in sequence through pipelines. The rotary drum granulation cylinder and the rotary drying cylinder are respectively equipped with first The transmission system and the second transmission system, the drum granulation cylinder and the rotary drying cylinder are installed on the base obliquely;

[0044] Gas-filled elastic sulfur wrapping component C: includes a nitrogen heater, a high-speed shear stirring heater and a sulfur wrap...

Embodiment 2

[0052] Utilize the application of the preparation device of a kind of dual-function slow-release nitrogen fertilizer described in embodiment 1, its technical process is as follows figure 1 shown, including the following steps:

[0053] (a) Add urea, formaldehyde and additives with a molar ratio of 1:1 to 4.5:1 to the urea-formaldehyde heating polymerization part, heat to 60°C to 80°C, and react and polymerize to obtain a liquid urea-formaldehyde polymer;

[0054] (b) putting the liquid urea-formaldehyde polymer into the ammonium chloride-urea-formaldehyde heating mixing part, and feeding a certain amount of ammonium chloride, the quality of the liquid urea-formaldehyde polymer being 5% to 25% of the ammonium chloride consumption, Heat to 70°C-90°C, stir and mix to obtain the mixed material;

[0055] (c) The mixed material is introduced into the drum granulation cylinder, and the rotating speed of the drum granulation cylinder is adjusted to 10rpm-60rpm through the first speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com