Process for preparing granular patassium formate and its pelletizing equipment

A granulation equipment and potassium formate technology, applied in the field of potassium formate preparation, can solve the problems of high production cost, uneconomical application, complicated process route, etc., meet the requirements of shape and particle size, increase the ability of exporting foreign exchange, and produce The effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Carbon monoxide gas concentration: 93% after purification;

[0040] Potassium hydroxide solution adopts the potassium hydroxide product produced by ionic membrane method, and concentration is 25% by weight;

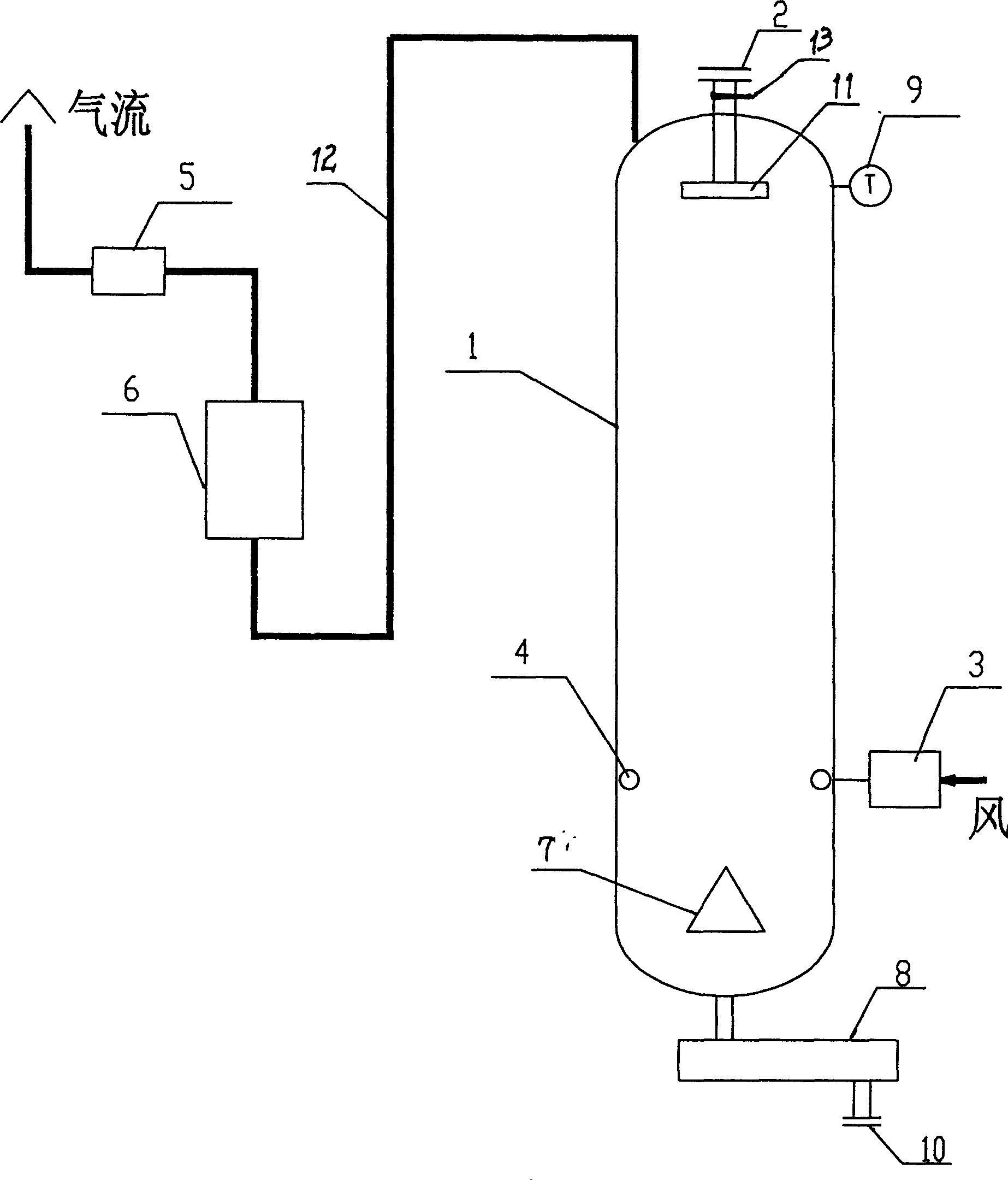

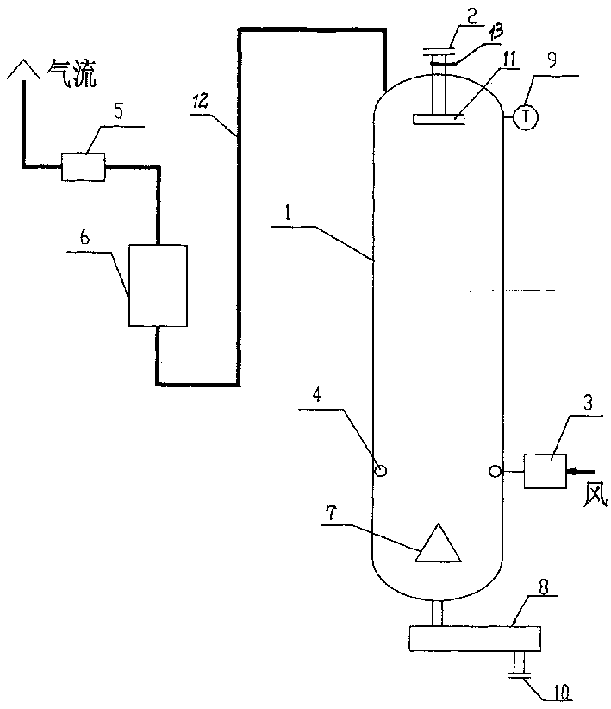

[0041] Pass carbon monoxide gas with a molar ratio of 2:1 into the potassium hydroxide solution, and synthesize and react for 4 hours at a temperature of 225°C and a pressure of 2.3Mpa to obtain a dilute solution of potassium formate product. Evaporate the above dilute potassium formate product solution at normal pressure 180°C to saturation to obtain potassium formate liquid product. Evaporate the above potassium formate liquid product at normal pressure 185°C to a molten state, then air flow cooling and crystallization at normal pressure and 110°C to obtain spherical potassium formate granules.

Embodiment 2

[0043] Carbon monoxide gas concentration: 90% after purification;

[0044] Potassium hydroxide solution adopts the potassium hydroxide product produced by ionic membrane method, and concentration is 20% by weight;

[0045] Pass carbon monoxide gas with a molar ratio of 1:1 into the potassium hydroxide solution, the mass ratio of potassium hydroxide to carbon monoxide is 3:1, and the synthesis reaction is carried out at a temperature of 200°C and a pressure of 3.5Mpa for 3 hours to obtain dilute potassium formate product solution. Evaporate the above dilute solution of potassium formate product at normal pressure 185°C to saturation to obtain potassium formate liquid product. Evaporate the above potassium formate liquid product at normal pressure 190°C to a molten state, then air flow cooling and crystallization at normal pressure and 150°C to obtain spherical potassium formate granules.

Embodiment 3

[0047] Carbon monoxide gas concentration: 88% after purification;

[0048] Potassium hydroxide solution adopts the potassium hydroxide product produced by ionic membrane method, and concentration is 20% by weight;

[0049] Pass carbon monoxide gas with a molar ratio of 3:1 into the potassium hydroxide solution, the mass ratio of potassium hydroxide to carbon monoxide is 2:1, and synthesize and react for 5 hours at a temperature of 210°C and a pressure of 2Mpa to obtain a dilute solution of potassium formate product . Evaporate the above dilute potassium formate product solution at normal pressure 195°C to saturation to obtain potassium formate liquid product. Evaporate the above potassium formate liquid product at normal pressure 200°C to a molten state, then airflow cooling and crystallization at normal pressure and 130°C to obtain spherical potassium formate granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com