A method for separating and removing arsenic by combining iron-manganese composite with superconducting magnetic

A technology of superconducting magnetism and composite oxides, applied in the directions of alkali metal compounds, chemical instruments and methods, water pollutants, etc., to simplify the process, reduce the cost of use, and realize the effect of recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

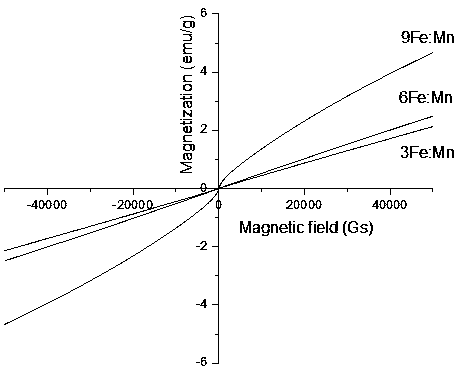

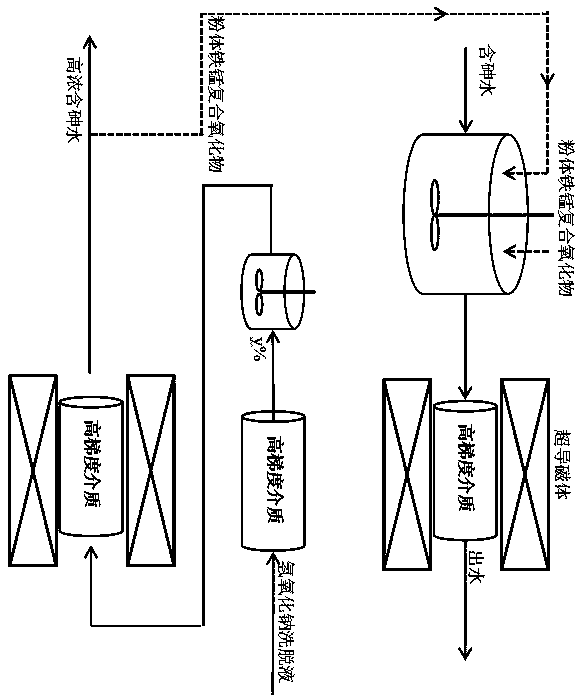

[0029] Ferrous salt and potassium permanganate As a raw material, ensure that the total molar concentration of iron and manganese salts is 2.0 mol / L, and prepare iron-manganese composite oxides with a Fe / Mn molar ratio of 3:1. The above-mentioned composite iron-manganese oxide directly passes through a 1000-mesh wet vibrating screen, and the intercepted part is washed and dried to make a powdered iron-manganese composite oxide; the passed part is returned to the material preparation link. Put the powdered iron-manganese composite oxide directly into the arsenic-containing water to be treated, which is mainly trivalent arsenic, which can be stirred with various equipment, such as mixing tanks, pipeline mixers, etc., and can also be mixed using natural water conservancy conditions, such as Dosing in the upstream, using the water flow to mix itself. The iron-manganese composite oxide and arsenic-containing water are fully mixed for 10 minutes to achieve good arsenic removal e...

Embodiment 2

[0032] Rural arsenic pollutes groundwater with an arsenic concentration of 50mg / l, and the main pollutants are trivalent arsenic and pentavalent arsenic. Ferrous salt ferric salt and potassium permanganate As raw material, ensure that the total molar concentration of iron and manganese salts is 3.0mol / L, prepare Fe 2+ / Mn molar ratio is 3:1, Fe 3+An iron-manganese composite oxide with a molar ratio of 4:1 to Mn and a molar ratio of Fe / Mn to 7:1. Separating components with a diameter of more than 10 μm by a cyclone classifier, washing and drying to obtain powder iron-manganese composite oxides. After adding 2g / l of iron-manganese composite oxide with an iron-manganese ratio of 7:1, the arsenic concentration dropped to 0.01mg / l. The magnetic induction intensity of the superconducting magnet is greater than 5T, and the water treatment volume of a single set of superconducting magnetic separator is 600 cubic meters per hour. After the iron-manganese composite oxide adsorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com