A kind of production method of large particle ammonium sulfate

A production method and technology of ammonium sulfate, applied in ammonium salt fertilizer, nitrogen fertilizer, agriculture, etc., can solve problems such as ammonium sulfate granulation difficulties, and achieve the effects of good product quality, effective use of resources, and control of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

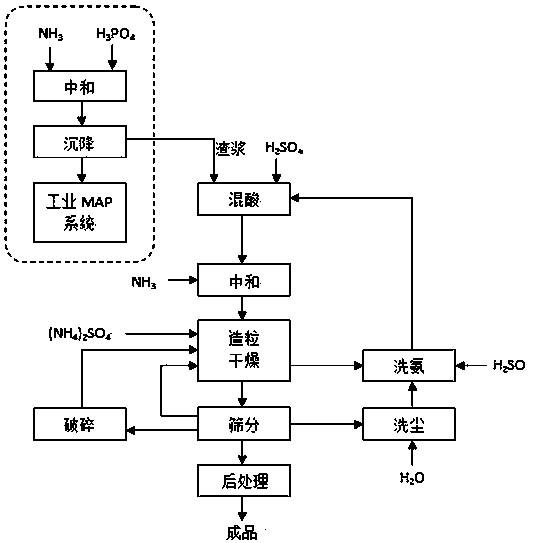

[0022] Such as figure 1 Shown, a kind of production method of large particle ammonium sulfate, this method may further comprise the steps:

[0023] Step 1: Mix the slurry produced in the process of producing industrial phosphoric acid by wet-process phosphoric acid or the solid waste generated by press filtration in the process of producing industrial phosphoric acid in wet-process phosphoric acid with sulfuric acid and tail washing solution in a ratio of 1:10:1 to form a mixed acid;

[0024] Step 2: adding the mixed acid obtained in step 1 into ammonia gas, carrying out neutralization reaction, controlling the pH value to 3.0, and obtaining ammonium sulfate slurry;

[0025] Step 3: Send the ammonium sulfate slurry obtained in step 2 into a granulator, granulate and dry the masterbatch in the granulator, and control the temperature in the granulator to 160-180°C to obtain large-grained ammonium sulfate;

[0026] Step 4: Screen the large-grained ammonium sulfate obtained in st...

Embodiment 2

[0034] Such as figure 1 Shown, a kind of production method of large particle ammonium sulfate, this method may further comprise the steps:

[0035] Step 1: Mix the slurry generated during the production of industrial phosphoric acid by wet-process phosphoric acid with sulfuric acid and tail washing solution in a ratio of 1:10:0.6 to form a mixed acid;

[0036] Step 2: adding the mixed acid obtained in step 1 into ammonia gas, carrying out neutralization reaction, controlling the pH value to 4.0, and obtaining ammonium sulfate slurry;

[0037] Step 3: Send the ammonium sulfate slurry obtained in step 2 into a granulator, granulate and dry the masterbatch in the granulator, and control the temperature in the granulator to 180-200°C to obtain large-grained ammonium sulfate;

[0038] Step 4: Screen the large-grained ammonium sulfate obtained in step 3, and the particles with a particle diameter less than 2 mm are returned to the granulator as a masterbatch, and those with a parti...

Embodiment 3

[0046] Such as figure 1 Shown, a kind of production method of large particle ammonium sulfate, this method may further comprise the steps:

[0047] Step 1: Mix the slurry generated during the production of industrial phosphoric acid by wet-process phosphoric acid with sulfuric acid and tail washing solution in a ratio of 0.8:10:1 to form a mixed acid;

[0048] Step 2: adding the mixed acid obtained in step 1 into ammonia gas, carrying out neutralization reaction, controlling the pH value to 5.0, and obtaining ammonium sulfate slurry;

[0049] Step 3: Send the ammonium sulfate slurry obtained in step 2 into a granulator, granulate and dry the masterbatch in the granulator, and control the temperature in the granulator to 180-200°C to obtain large-grained ammonium sulfate;

[0050]Step 4: Sieve and classify the large-grained ammonium sulfate obtained in step 3. Particles with a particle size of less than 2 mm are returned to the granulator as a masterbatch, and those with a par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com