A preparation method of degradable hemostatic microspheres capable of reducing pigmentation

A technology of pigmentation and microspheres, which is applied in the field of preparation of degradable hemostatic microspheres, can solve the problems of regenerated cellulose degradation, no reduction of pigmentation, poor environmental adaptability, etc., and achieve industrial production, good hemostatic performance, and clear The effect of free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

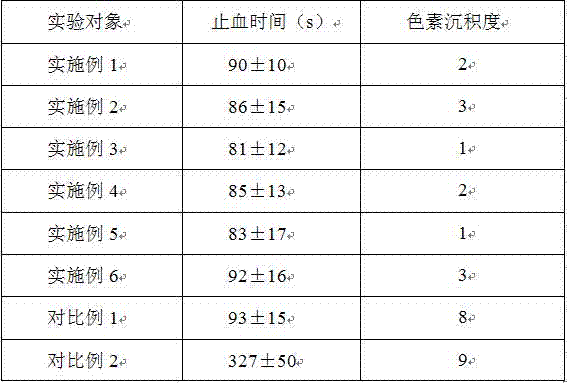

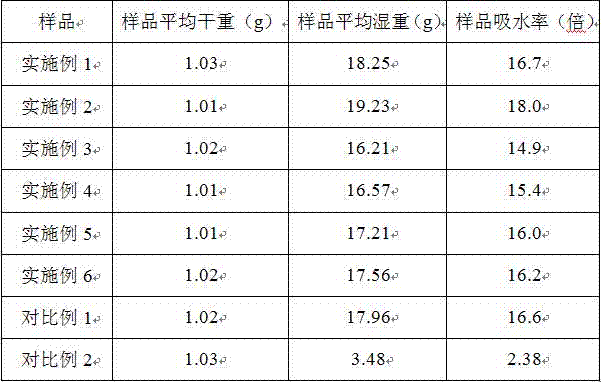

Examples

Embodiment 1

[0024] Mix 100ml gelatinized 5% (g / ml) starch aqueous solution with 25ml 1% (g / ml) chitosan solution evenly, adjust the pH of the system to 8 with sodium hydroxide. Then 2g of Span 80 and 0.5g of Tween 60 were added as emulsifiers, and stirred at 50°C for 200 minutes. After stopping the reaction and standing for stratification, the upper layer solution was poured out, leaving a layer of milky white liquid. Then add 10ml of fullererol (average hydroxyl number is 10) 1% (g / ml) aqueous solution to the milky white liquid, stir for 30 minutes and mix evenly, then add 0.1g glutaraldehyde and continue stirring for 400 minutes, stop the reaction, purify and filter , and then dried at 40°C to obtain a light yellow powdery solid (yield 93.6%).

Embodiment 2

[0026] Mix 130ml gelatinized 3% (g / ml) starch aqueous solution with 15ml 2% (g / ml) chitosan solution evenly, adjust the pH of the system to 9 with sodium hydroxide. Then, 1 g of Span 80 and 1.5 g of Tween 60 were added as emulsifiers, and stirred at 45° C. for 100 minutes. After stopping the reaction and standing for stratification, the upper layer solution was poured out, leaving a layer of milky white liquid. Then add 20ml of fullererol (average hydroxyl number is 5) 1.5% (g / ml) aqueous solution to the milky white liquid, stir for 50 minutes and mix evenly, then add 0.07g formaldehyde and continue to stir for 500 minutes, stop the reaction, purify and filter, then Drying at 20°C gave a light yellow powdery solid (91.3% yield).

Embodiment 3

[0028] Mix 60ml of gelatinized 8% (g / ml) starch aqueous solution with 50ml of 0.5% (g / ml) chitosan solution, and adjust the pH of the system to 10 with sodium hydroxide. Then, 1 g of Span 80 and 1 g of Tween 60 were added as emulsifiers, and stirred at 55° C. for 250 minutes. After stopping the reaction and standing for stratification, the upper layer solution was poured out, leaving a layer of milky white liquid. Then add 1ml of fullererol (average hydroxyl number is 20) 5% (g / ml) aqueous solution to the milky white liquid, stir for 40 minutes and mix evenly, then add 0.3g epichlorohydrin and continue stirring for 60 minutes to stop the reaction purification After filtering and drying at 60°C, a light yellow powdery solid was obtained (yield: 88.9%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com