Antibacterial and anticoagulant polymer material, preparation method and application thereof

A polymer material, anti-coagulation technology, applied in anti-coagulation treatment, transportation and packaging, drug packaging and other directions, can solve the problems of reducing biological activity, inflammatory infection, disappearance, etc., to achieve good comprehensive performance, good antibacterial and anti- The effect of blood coagulation, good function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the preparation method of the antibacterial and anticoagulant polymer material of the present invention, there is no special limitation on the method of mixing the materials containing polymer matrix material, nitric oxide donor substance, hydrophilic material and antibacterial agent, For example, a melt kneading method may be used. The present invention has no special limitation on the mixing conditions, and various mixing methods in the prior art can be used in the present invention. For example, mixing can be performed on extruders, open mills and internal mixers. From the perspective of product performance, preferably, the kneading conditions may include: a kneading temperature of 20-400° C.; a kneading time of 2 minutes to 2 hours.

[0028] According to the present invention, in the embodiment where the mixing is carried out in an extruder, the rotating speed of the extruder can be selected according to the type of polymer matrix material, specifically, the rot...

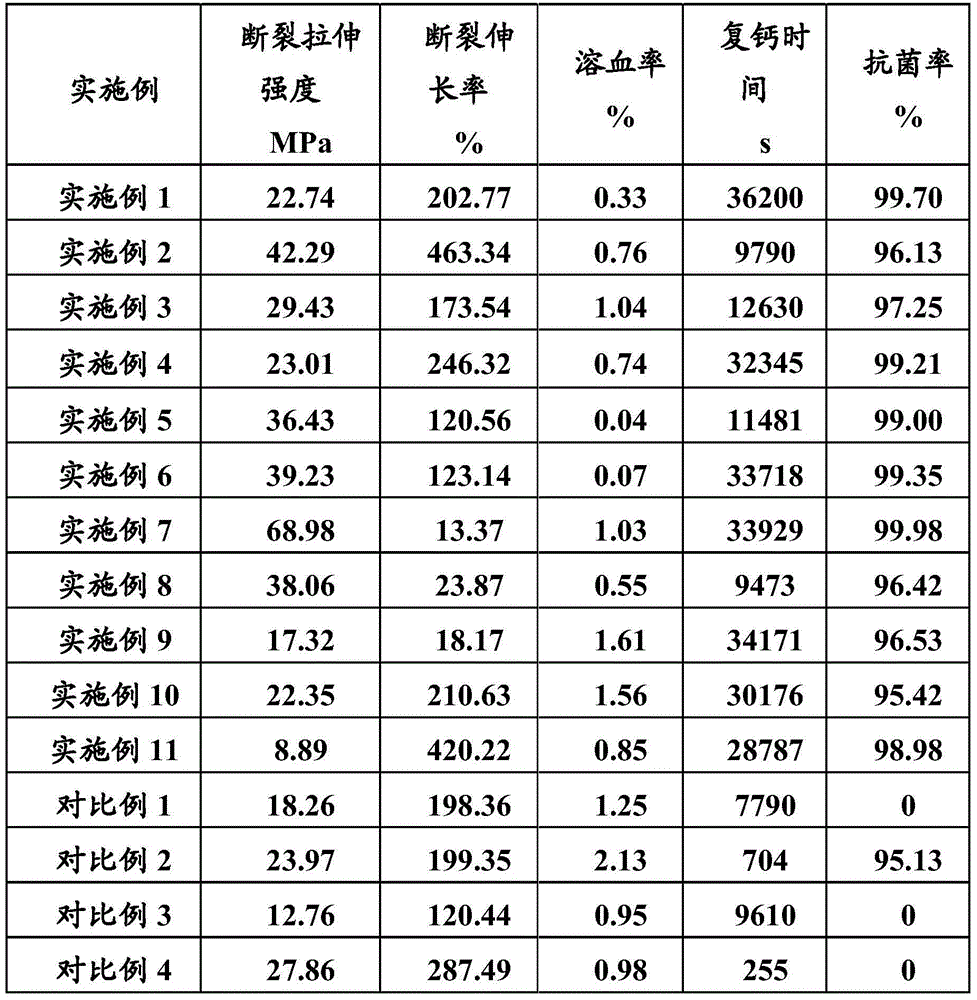

Embodiment 1

[0050] 1. 20g S-nitrosoglutathione (Suzhou Yake Chemical Reagent Co., Ltd., Mw: 335.3), 30g nano-titanium dioxide (obtained by Hangzhou Wanjing New Material Co., Ltd., trade name VK-TA18S) and 20g polyethyleneimine (Sinopharm Chemical Reagent Beijing Co., Ltd., Mw: 7000, M W / M n =2.5) Add 300ml of ethanol, stir well at 40°C for 30 minutes to mix evenly, then ultrasonically disperse at 60°C (ultrasonic power is 1600W) for 30 minutes, and finally dry under reduced pressure at 40°C and 0.08MPa to constant weight. spare.

[0051] 2. get the mixture that 100g polyether polyurethane (BASF, trade mark is E1195A) and 70g step 1) prepare through extruder mixing, the screw speed of extruder is 600 rev / mins, 250 ℃ of mixing temperatures, extrude After being granulated, the antibacterial and anticoagulant polymer material is obtained.

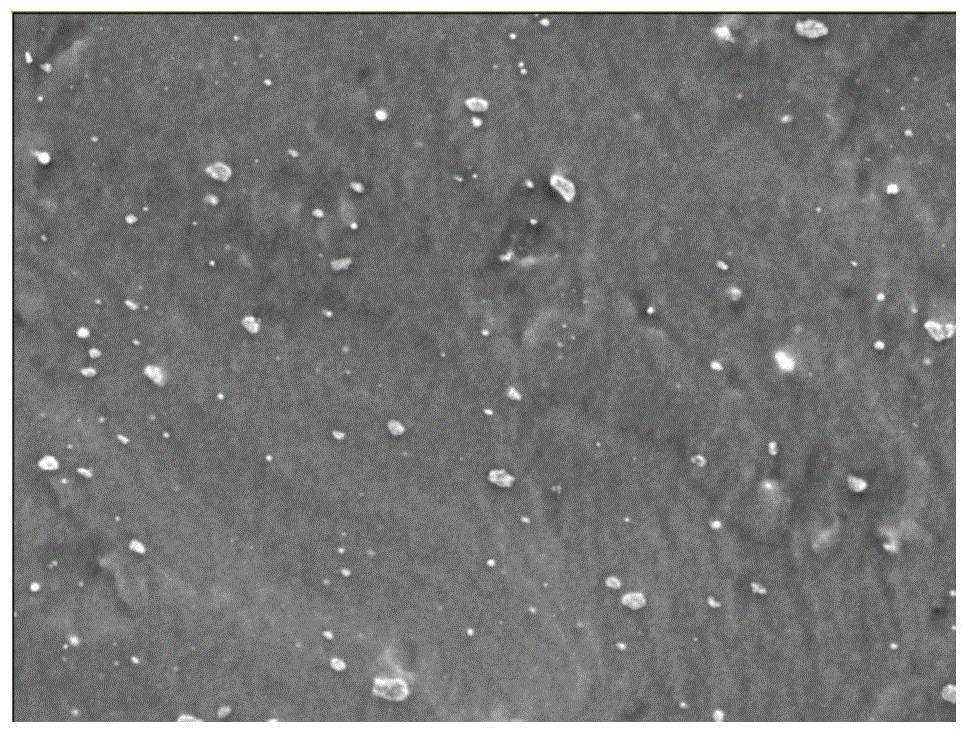

[0052] The static platelet adhesion scanning electron micrograph in vitro of the polyether polyurethane (matrix material) used in this embodiment is s...

Embodiment 2

[0055] 1. 10g S-nitroso serum albumin (Shanghai Times Biotechnology Co., Ltd., grade: BR, total protein content: ≥95.0% by weight), 10g chitosan (Shanghai Boao Biotechnology Co., Ltd., weight average molecular weight 15000, light yellow powder, deacetylation degree ≥ 90%) and 5g of polyethylene glycol (Beijing Lanli Fine Chemicals, weight average molecular weight: 400) were added to 100ml of ethanol, fully stirred at 25°C for 100 minutes to mix evenly, and then Ultrasonic disperse at 25°C (ultrasonic power is 1600W) for 60 minutes, and finally dry under reduced pressure at 40°C and 0.08MPa to constant weight for future use.

[0056] 2. get the mixture that 100g polypropylene (Japan C hours ISSO company, trade mark XF1800) and 25g step 1) prepare through extruder mixing, the screw speed of extruder is 400 rev / mins, mixing temperature 220 ℃ , and then granulated to obtain an antibacterial and anticoagulant polymer material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com