Free piston stirling engine with magnetofluid for power generation and work method

A technology of Stirling engine and magnetic fluid generator, applied in the field of free-piston Stirling engine, can solve the problems of reduced thrust, large volume and large heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

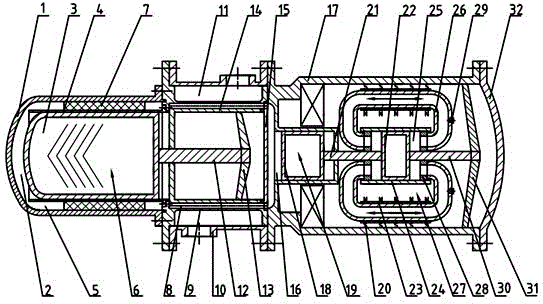

[0017] Combine below figure 1 Further illustrate the structure of the free-piston Stirling engine with magnetic fluid power generation of the present invention. The gas distribution piston system 6 is composed of double-layer cylinders (outer cylinder 1 and inner cylinder 4), and the interlayer is composed of heating chamber 5, regenerator 7 and gas passage 8 respectively. The inner cylinder 4 is open in the left head heating area.

[0018] When the gas is heated in the expansion chamber 2 and the heating chamber 5, it is heated and expands in the expansion chamber 2, driving the distributing piston 3 to move to the right, compressing the first leaf spring 13 to generate a certain potential energy, when the distributing piston 3 moves to The first leaf spring 13 behind the right bottom has the maximum potential energy. At this time, the restoring force of the first leaf spring 13 is greater than the gas pressure, and pushes the gas distribution piston 3 to move to the left in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com