Preparation method of dual antibacterial emulsion gel

An emulsion gel, double technology, applied in food preservation, fruit and vegetable preservation, food science, etc., can solve the problems of complicated preparation process, unsuitable for anti-corrosion, fresh-keeping, high production cost, etc., and achieve simple preparation process, fast formation speed, The effect of long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Dissolve 1g of chitosan in 100g of 2% glacial acetic acid aqueous solution to prepare a chitosan solution, stir with a magnetic stirrer until the chitosan dissolves, then centrifuge at 3000r / min for 15min with a centrifuge Remove insoluble matter, vacuum degassing, obtain chitosan solution;

[0032] 2. Mix 5g cinnamaldehyde, 5g medium-chain glycerides, and 7.5g Tween 20, and stir on a magnetic stirrer for 5 minutes to make it evenly mixed, as the oil phase, and then slowly add it dropwise to 82.5g distilled water, continuously Stir for 15min to form a cinnamaldehyde emulsion;

[0033] 3. Slowly add 40g of cinnamaldehyde emulsion dropwise to 100g of chitosan solution, so that the mass ratio of chitosan and cinnamaldehyde is 1:2, adjust the pH of the system to be 4.6, keep stirring at 40°C for 20min, and let it stand for 30min. Instantly.

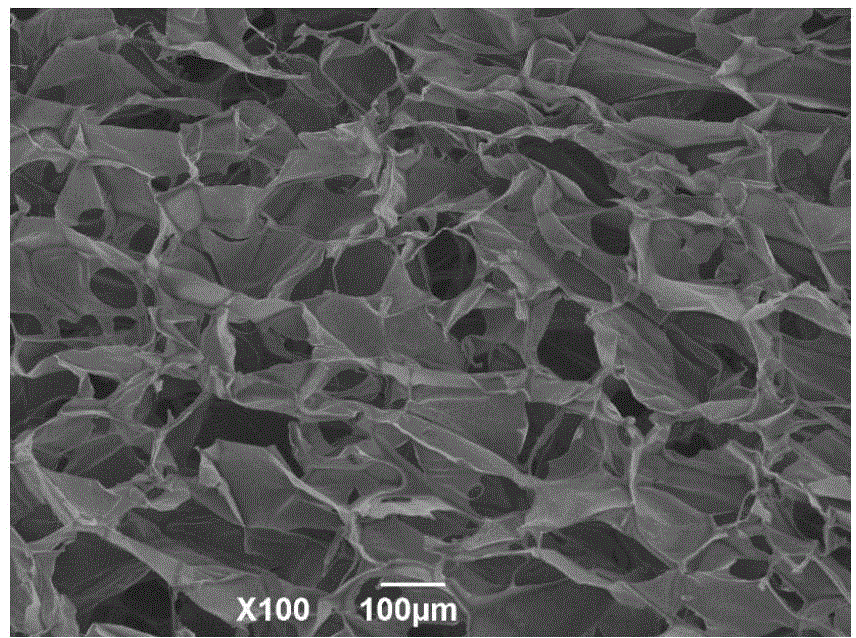

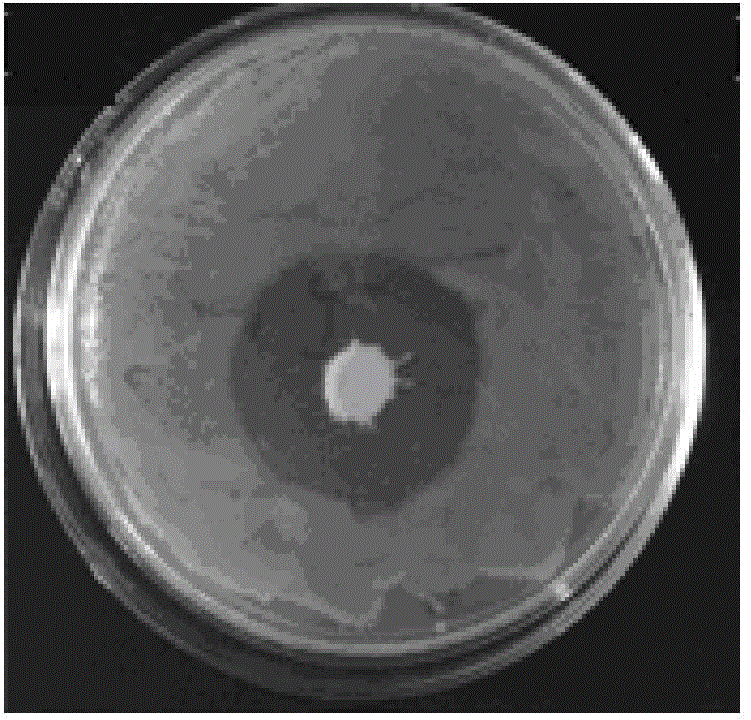

[0034] Detect respectively the chitosan solution that step 1) obtains, step 2) the cinnamic aldehyde emulsion that obtains and s...

Embodiment 2

[0036] 1. Dissolve 0.5g of chitosan in 100g of 1% glacial acetic acid aqueous solution to prepare a chitosan solution, stir with a magnetic stirrer until the chitosan dissolves, then centrifuge for 15 minutes to remove insoluble matter, and vacuum degass , to obtain chitosan solution;

[0037] 2. Mix 6g cinnamaldehyde, 6g soybean oil, and 7.5g Tween 80, and stir on a magnetic stirrer for 5 minutes to make it evenly mixed as the oil phase, then slowly add it dropwise to 80.5g distilled water, and continue stirring for 15 minutes , forming a cinnamaldehyde emulsion;

[0038] 3. Slowly add 25g of cinnamaldehyde emulsion dropwise to 100g of chitosan solution, so that the mass ratio of chitosan and cinnamaldehyde is 1:3, adjust the pH of the system to be 4.4, keep stirring at 20°C for 30min, and let it stand for 45min. Instantly.

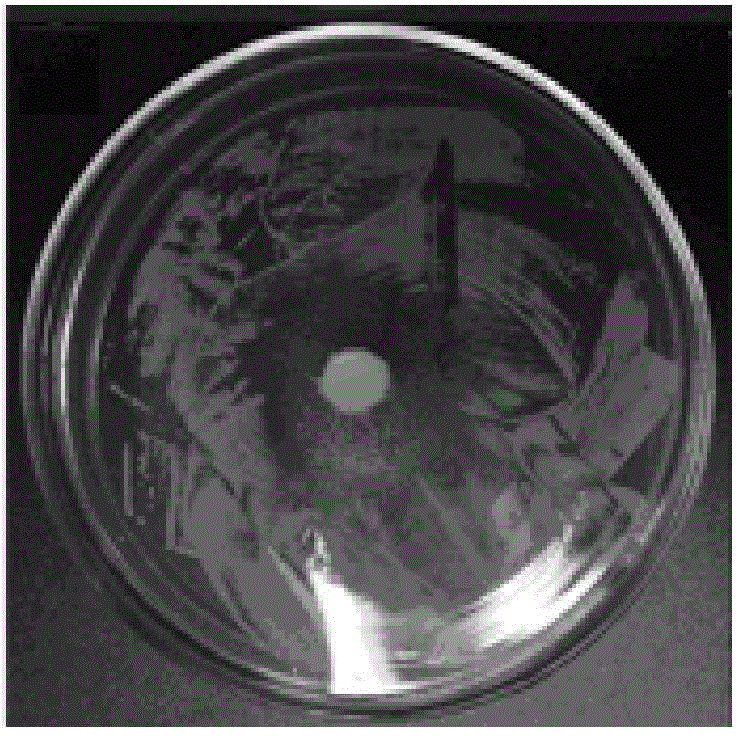

[0039] Detect the bacteriostasis situation of chitosan solution, cinnamaldehyde emulsion and emulsion gel respectively to escherichia coli and Staphyl...

Embodiment 3

[0041] 1. Dissolve 2g of chitosan in 100g of 3% glacial acetic acid aqueous solution to prepare a chitosan solution, stir with a magnetic stirrer until the chitosan dissolves, then use a centrifuge for 15 minutes to remove insolubles, vacuum degassing, Obtain chitosan solution;

[0042] 2. Mix 2g of cinnamaldehyde, 8g of medium-chain glycerides, and 10g of polyoxyethylene 20, and stir on a magnetic stirrer to make it evenly mixed as the oil phase, then slowly add it dropwise to 80g of distilled water, and continue stirring for 15 minutes , forming a cinnamaldehyde emulsion;

[0043] 3. Slowly add 500g of cinnamaldehyde emulsion dropwise to 100g of chitosan solution, so that the mass ratio of chitosan and cinnamaldehyde is 1:5, adjust the pH of the system to 5.0, keep stirring at 60°C for 15min, and let it stand for 10min. Instantly.

[0044] Detect the bacteriostasis situation of chitosan solution, cinnamaldehyde emulsion and emulsion gel respectively to escherichia coli and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com