Compound ketoconazole lotion for hair

A technology of compound ketoconazole and ketoconazole, which is applied in anti-inflammatory agents, pharmaceutical formulations, hair care, etc., can solve problems such as hair follicle damage, and achieve the effect of improving hair quality, stable performance, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

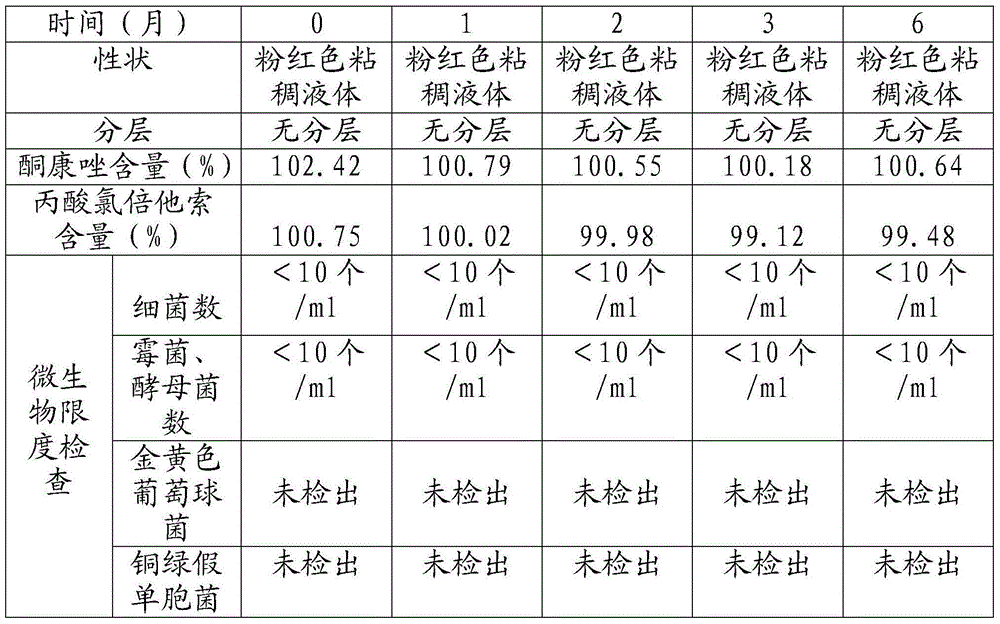

Examples

Embodiment 1

[0024] Add purified water into a clean emulsification pot, start stirring and heat to 80-85°C, then add 170g of alkyl glucoside, 90g of ammonium lauryl sulfate, 30g of cocoamidopropyl betaine, and 30g of cocoyl monoethanolamide Stir to dissolve, then add 15g of ketoconazole and 0.25g of clobetasol propionate in propylene glycol, rinse the raw material dissolving pot with propylene glycol, add the rinse solution into the emulsification pot, start stirring, and homogenize for 10 minutes.

[0025] Pour 4.5g of cationic guar gum and 1g of disodium edetate solution dissolved in purified water into the emulsification pot, start stirring, and homogenize for 10 minutes. Then, when the material in the emulsification pot is cooled to 45°C, add 0.2g of pigment and 15g of sodium bisulfite aqueous solution into the emulsification pot through the feeding port, stir for 10 minutes, continue cooling, and cool to room temperature.

[0026] Wherein, the total consumption of purified water is 61...

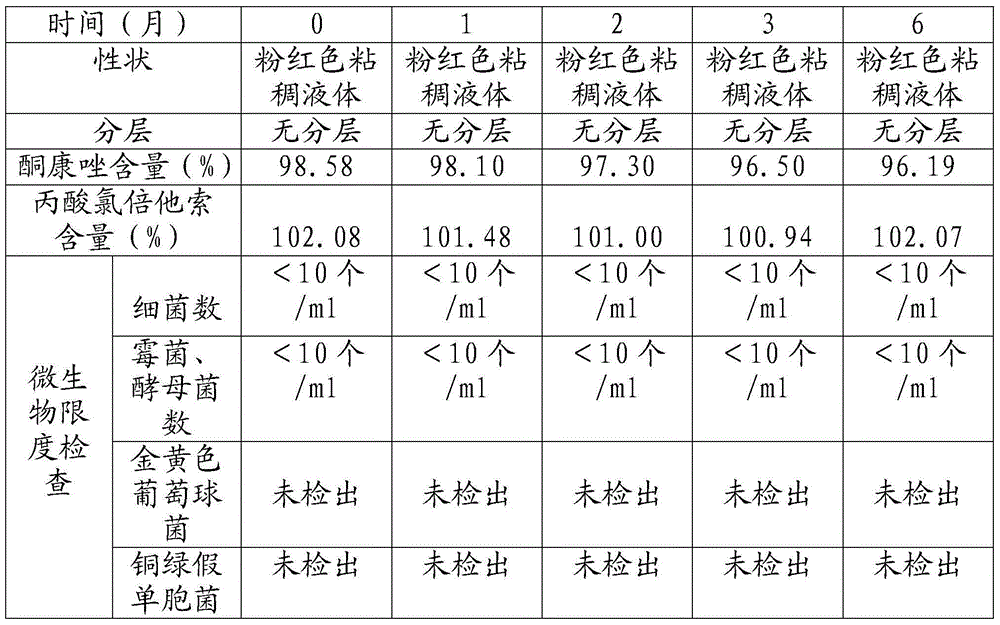

Embodiment 2

[0028] Add purified water into a clean emulsification pot, start stirring and heat to 80-85°C, then add 160g of alkyl glucoside, 60g of ammonium lauryl sulfate, 20g of cocoamidopropyl betaine, and 20g of cocoyl monoethanolamide Stir to dissolve, then add 15g of ketoconazole and 0.25g of clobetasol propionate in propylene glycol, rinse the raw material dissolving pot with propylene glycol, add the rinse solution into the emulsification pot, start stirring, and homogenize for 10 minutes.

[0029] Pour 2 g of cationic guar gum and 0.5 g of disodium edetate solution dissolved in purified water into the emulsification pot, start stirring, and homogenize for 10 minutes. Then when the material in the emulsification pot is cooled to 45°C, add 0.1g of pigment and 5g of sodium bisulfite aqueous solution into the emulsification pot through the feeding port, stir for 10 minutes, continue cooling, and cool to room temperature.

[0030] Wherein, the total consumption of purified water is 66...

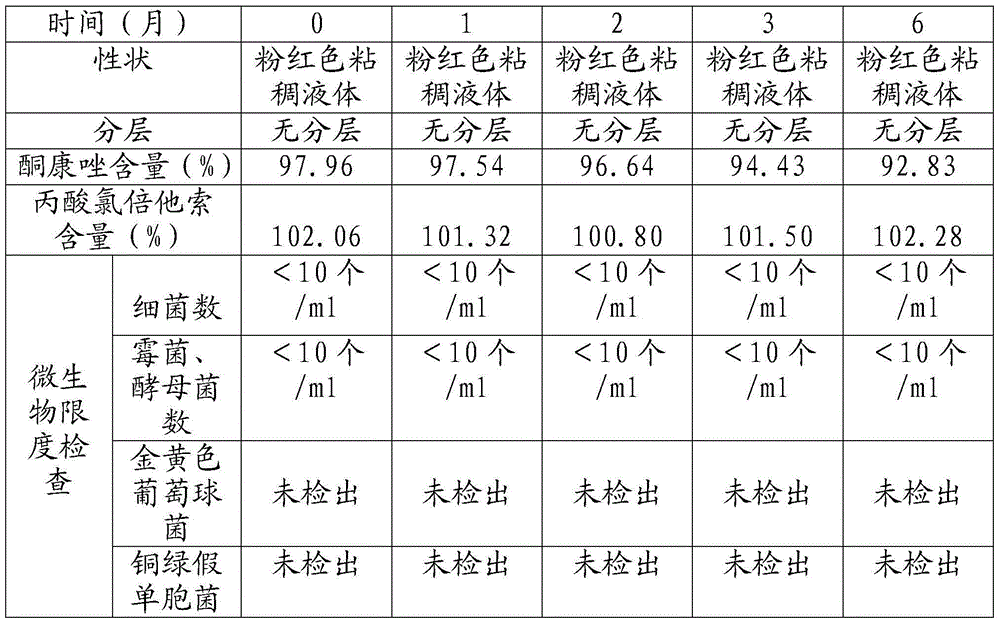

Embodiment 3

[0032] Add purified water into a clean emulsification pot, start stirring and heat to 80-85°C, then add 180g of alkyl glucoside, 100g of ammonium lauryl sulfate, 40g of cocoamidopropyl betaine, and 45g of cocoyl monoethanolamide Stir to dissolve, then add 15g of ketoconazole and 0.25g of clobetasol propionate in propylene glycol, rinse the raw material dissolving pot with propylene glycol, add the rinse solution into the emulsification pot, start stirring, and homogenize for 10 minutes.

[0033] Pour 5 g of cationic guar gum and 1.5 g of disodium edetate solution dissolved in purified water into the emulsification pot, start stirring, and homogenize for 10 minutes. Then, when the material in the emulsification pot is cooled to 45°C, add 0.3g of pigment and 30g of sodium bisulfite aqueous solution into the emulsification pot through the feeding port, stir for 10 minutes, continue cooling, and cool to room temperature.

[0034] Wherein, the total consumption of purified water is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com