Microporous chitosan oligosaccharide/sodium alginate hemostasis granule and preparation method thereof

A technology of sodium alginate and hemostatic granules is applied in the field of biomedical technical materials, which can solve the problems of high cost, complicated process, unenvironmental protection and the like, and achieve the effects of better effect, good biocompatibility and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

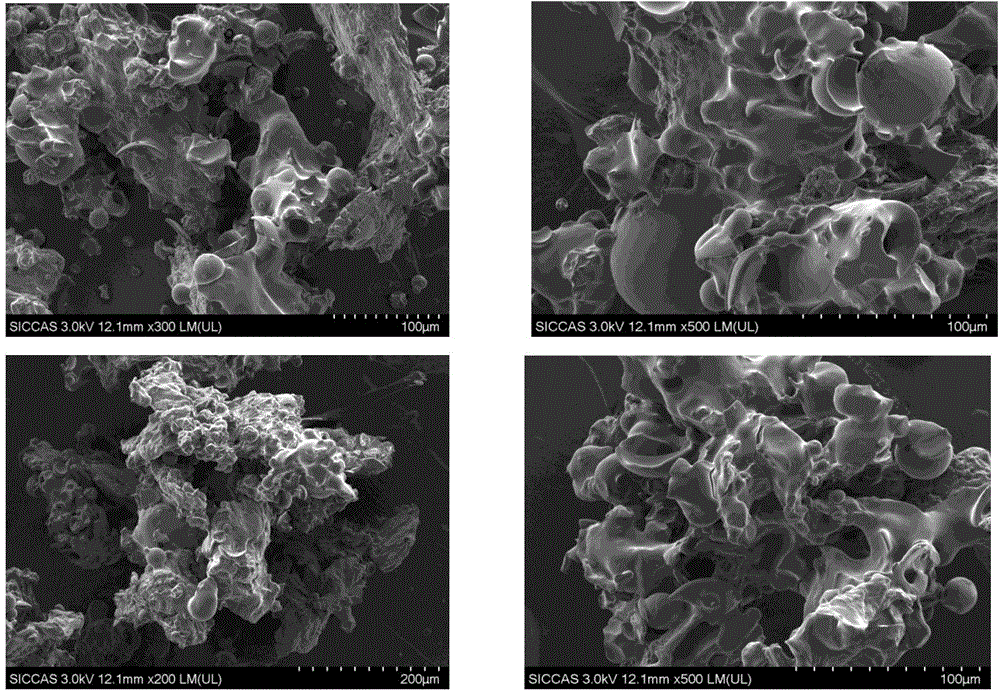

Image

Examples

Embodiment 1

[0027] (1) Get 1470 grams of chitosan oligosaccharide powder, 1500 grams of sodium alginate and 30 grams of calcium chloride, crush at high speed, pass through a 500-mesh sieve, and set aside;

[0028] (2) Heat the inlet air temperature of the fluidized granulator to 90°C, pour the chitosan oligosaccharide powder, sodium alginate powder, and calcium chloride powder obtained in step (1) into the fluidized granulator, and boil and mix with hot air for 5 minutes. Fully mix the raw materials, and control the internal temperature of the granulator at 50°C;

[0029] (3) Prepare 1.5wt% cellulose sodium salt solution, pass through an 80-mesh sieve to obtain a binder; then connect a peristaltic pump, and spray the binder into the granulator;

[0030] (4) After 30 minutes, observe the granulation situation, take a sample through a 40 / 150 mesh sieve, and observe whether it meets the standard; after the granulation reaches the standard, stop the peristaltic pump, dry it with hot air for 5...

Embodiment 2

[0032] (1) Get 1800 grams of chitosan oligosaccharides, 1170 grams of sodium alginate and 30 grams of calcium chloride, pulverize at a high speed, pass through a 500-mesh sieve, and set aside;

[0033] (2) Heat the inlet air temperature of the fluidized granulator to 80°C, pour the chitosan oligosaccharide powder, sodium alginate powder, and calcium chloride powder obtained in step (1) into the fluidized granulator, and boil and mix with hot air for 5 minutes. Fully mix the raw materials, and control the internal temperature of the granulator at 50°C;

[0034] (3) Prepare 2wt% sodium alginate solution, pass through an 80-mesh sieve to obtain a binder; then connect a peristaltic pump, and spray the binder into the granulator;

[0035] (4) After 30 minutes, observe the granulation situation, take a sample through a 40 / 150 mesh sieve, and observe whether it meets the standard; after the granulation reaches the standard, stop the peristaltic pump, dry it with hot air for 5 minutes...

Embodiment 3

[0037] (1) Get 1000 grams of chitosan oligosaccharide, 1970 grams of sodium alginate and 30 grams of calcium chloride, pulverize at a high speed, pass through a 500-mesh sieve, and set aside;

[0038] (2) Heat the inlet air temperature of the fluidized granulator to 90°C, pour the chitosan oligosaccharide powder, sodium alginate powder, and calcium chloride powder obtained in step (1) into the fluidized granulator, and boil and mix with hot air for 5 minutes. Fully mix the raw materials, and control the internal temperature of the granulator at 60°C;

[0039] (3) Prepare 1.5wt% sodium alginate solution, pass through a 80-mesh sieve to obtain a binder; then connect a peristaltic pump, and spray the binder into the granulator;

[0040](4) After 30 minutes, observe the granulation situation, take a sample through a 40 / 150 mesh sieve, and observe whether it meets the standard; after the granulation reaches the standard, stop the peristaltic pump, dry it with hot air for 5 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com