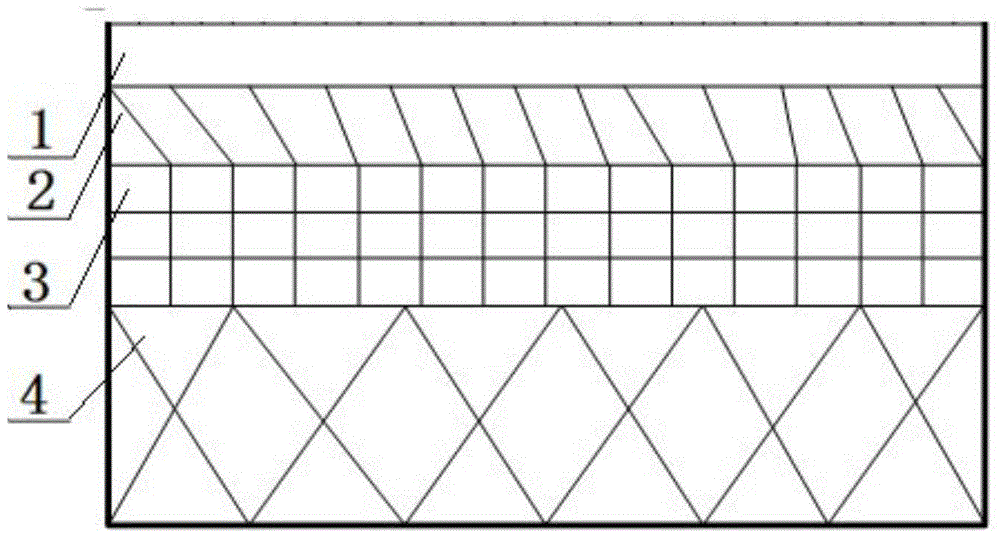

Nanofiltration membrane for seawater desalination and preparation method thereof

A nanofiltration membrane and hydrophilic technology, which is applied in the field of nanofiltration membrane for seawater desalination and its preparation, can solve the problems of only removing some bacteria, macromolecules, and large-particle organic matter in seawater, and cannot remove organic matter with small molecular hardness. , to achieve the effect of anti-pollution ability and performance improvement, high surface smoothness, good surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

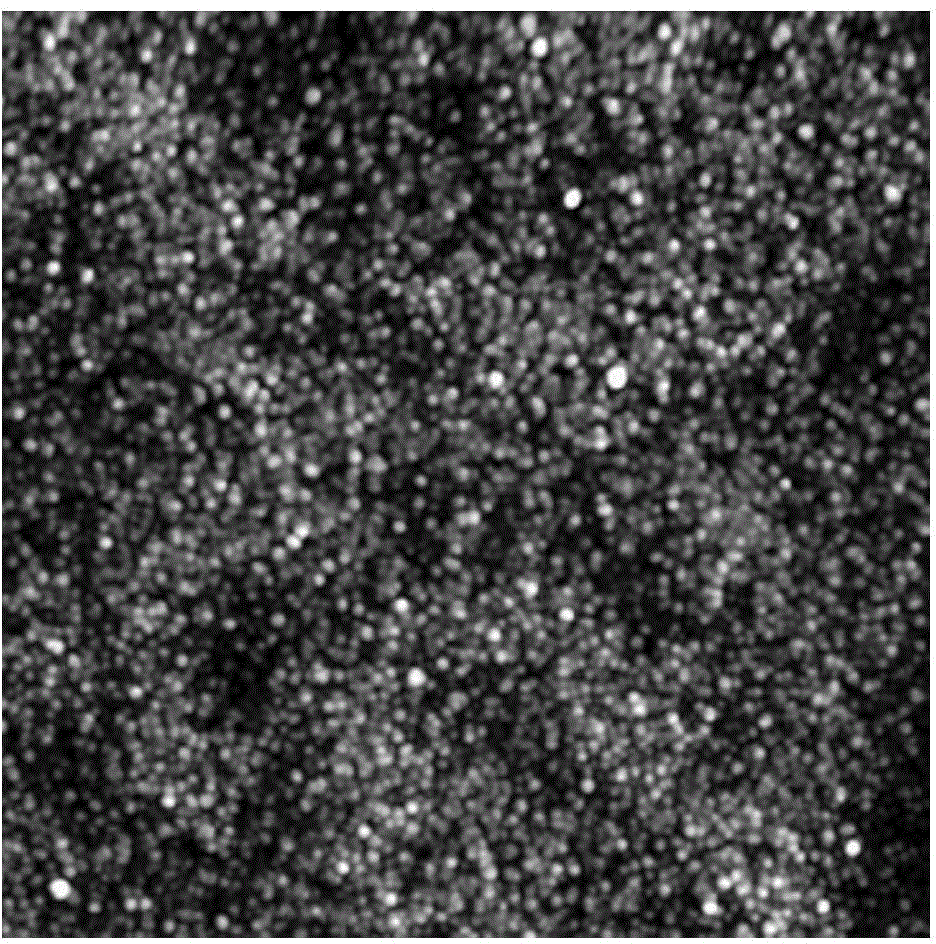

Image

Examples

Embodiment 1

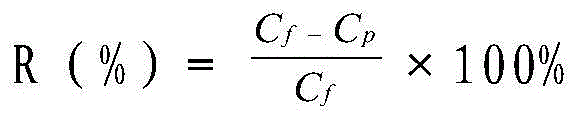

[0041] A preparation method of a nanofiltration membrane for seawater desalination, comprising the following steps:

[0042] (1) Preparation of polysulfone solution: Disperse 10 grams of isopropanol in 890 grams of N,N-dimethylformamide, stir at 1600 rpm for 30 minutes to completely dissolve the isopropanol; disperse 100 grams of yellowed polysulfone Put it in the mixed solution, and raise the temperature to 40°C, adjust the stirrer to stir and dissolve at 1400rpm for 12h, after it is completely dissolved, put the resulting solution in an oven with a vacuum degree of -80KPa for vacuum degassing for 10h, and obtain a polysulfone solution ;

[0043] (2) Preparation of polymer solution for ultra-thin porous transition layer:

[0044] A. Disperse 10 grams of isopropanol in 40 grams of N,N-dimethylformamide to obtain a mixed solution of pore-forming agent solvent;

[0045] B. Dissolve 15 grams of sulfonated polysulfone in the mixed solution of pore-forming agent solvent, and heat...

Embodiment 2

[0050] A preparation method of a nanofiltration membrane for seawater desalination, comprising the following steps:

[0051] (1) Preparation of polysulfone solution: Disperse 10 grams of ethylene glycol in 60 grams of N,N-dimethylacetamide, and mechanically stir at 1500 rpm for 30 minutes. After the ethylene glycol is completely dissolved, 30 grams of sulfone Disperse the polyethersulfone in the mixed solution, raise the temperature to 60°C, adjust the mechanical stirrer to stir and dissolve at 1300rpm for 12h, and after it is completely dissolved, place the obtained solution in an oven with a vacuum degree of -80KPa for degassing for 10h , to obtain polysulfone solution;

[0052] (2) Preparation of polymer solution for ultra-thin porous transition layer:

[0053] A. 1 gram of ethylene glycol is dispersed in 99 grams of N,N-dimethylacetamide to obtain a mixed solution;

[0054] B. Dissolve 5 grams of sulfonated polyethersulfone in the mixed solution, heat to 120°C and dissol...

Embodiment 3

[0059] A preparation method of a nanofiltration membrane for seawater desalination, comprising the following steps:

[0060] (1) Preparation of polysulfone solution: Disperse 5 grams of glycerol in 75 grams of dimethyl sulfoxide, and mechanically stir at 1700 rpm for 30 minutes. After all the solutions are dissolved, disperse 20 grams of cellulose triacetate in the mixed solution , and raised the temperature to 120°C, adjusted the mechanical stirrer to stir and dissolve at 1500rpm for 12h, after it was completely dissolved, put the obtained solution in an oven with a vacuum degree of -80KPa for degassing for 10h, and obtained a polysulfone solution;

[0061] (2) Preparation of polymer solution for ultra-thin porous transition layer:

[0062] A. 10 grams of glycerol are dispersed in 90 grams of dimethyl sulfoxide to obtain a mixed solution;

[0063] B. Dissolve 17.5 grams of cellulose triacetate in the mixed solution and heat to 120°C to dissolve until the solution is clear; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com