Preparation method of carbon spheres

A carbon ball, glucose solution technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of impurities, expensive equipment, large size, etc., to achieve short reaction time, reduce production Cost, Sphere Complete Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Use dilute hydrochloric acid to adjust the pH of the double deionized water to 3, use it as a solvent, dissolve it in glucose, and prepare a glucose solution with a concentration of 8g / 100ml;

[0032] 2) Take an appropriate amount of the above-mentioned glucose solution and put it in a 25ml stainless steel reaction kettle with a polytetrafluoroethylene lining, and place it in an oven at 180°C for 4 hours, and cool it down to room temperature naturally to obtain a carbon sphere solution;

[0033] 3) Centrifuge the above solution, and ultrasonically disperse and wash it with deionized water and absolute ethanol until the dispersion is clear after centrifugation;

[0034] 4) Dry the solid obtained after the above centrifugation in a vacuum oven at 80°C for 8 hours to obtain carbon spheres.

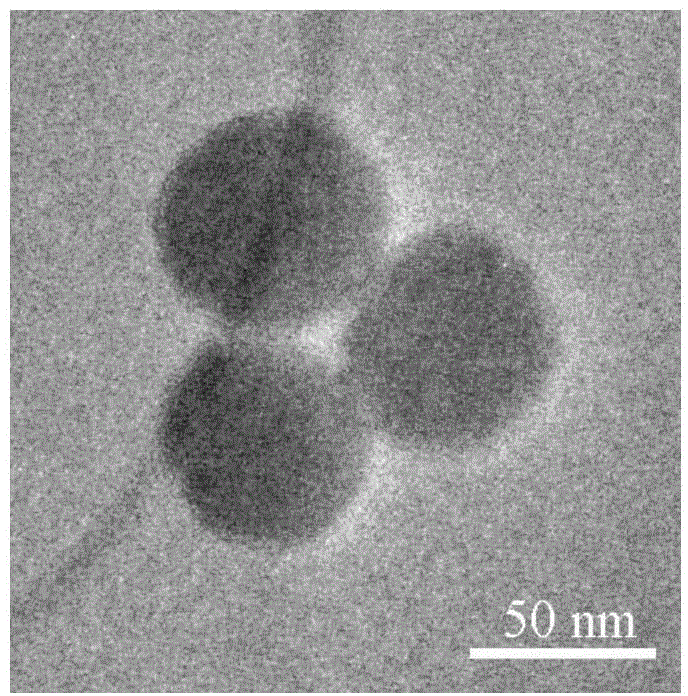

[0035] figure 1 Shown is the transmission electron micrograph of the carbon spheres obtained in Example 1. It can be seen from the figure that the diameter of the carbon spheres i...

Embodiment 2

[0037] 1) Use dilute hydrochloric acid to adjust the pH of the double deionized water to 6, use it as a solvent, dissolve it in glucose, and prepare a glucose solution with a concentration of 8g / 100ml;

[0038] 2) Take an appropriate amount of the above-mentioned glucose solution and put it in a 25ml stainless steel reaction kettle with a polytetrafluoroethylene lining, and place it in an oven at 180°C for 4 hours, and cool it down to room temperature naturally to obtain a carbon sphere solution;

[0039] 3) Centrifuge the above solution, and ultrasonically disperse and wash it with deionized water and absolute ethanol until the dispersion is clear after centrifugation;

[0040] 4) Dry the solid obtained after the above centrifugation in a vacuum oven at 80°C for 8 hours to obtain carbon spheres.

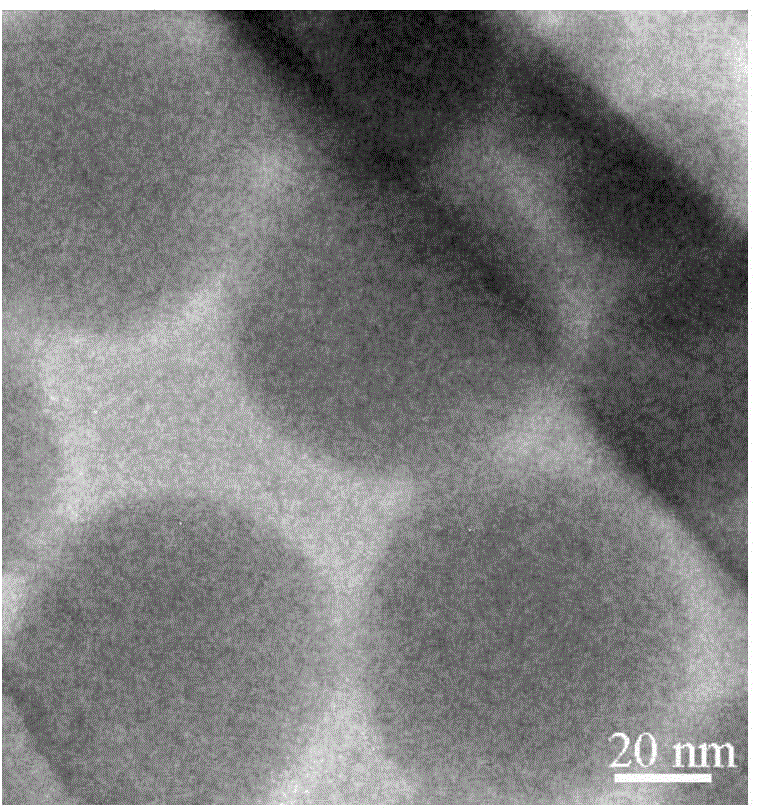

[0041] figure 2 Shown is the transmission electron micrograph of the carbon spheres obtained in Example 2. It can be seen from the figure that the diameter of the carbon spheres ...

Embodiment 3

[0043] 1) Use dilute hydrochloric acid to adjust the pH of the double deionized water to 9, use it as a solvent, dissolve it in glucose, and prepare a glucose solution with a concentration of 8g / 100ml;

[0044] 2) Take an appropriate amount of the above-mentioned glucose solution and put it in a 25ml stainless steel reaction kettle with a polytetrafluoroethylene lining, and place it in an oven at 180°C for 4 hours, and cool it down to room temperature naturally to obtain a carbon sphere solution;

[0045] 3) Centrifuge the above solution, and ultrasonically disperse and wash it with deionized water and absolute ethanol until the dispersion is clear after centrifugation;

[0046]4) Dry the solid obtained after the above centrifugation in a vacuum oven at 80°C for 8 hours to obtain carbon spheres.

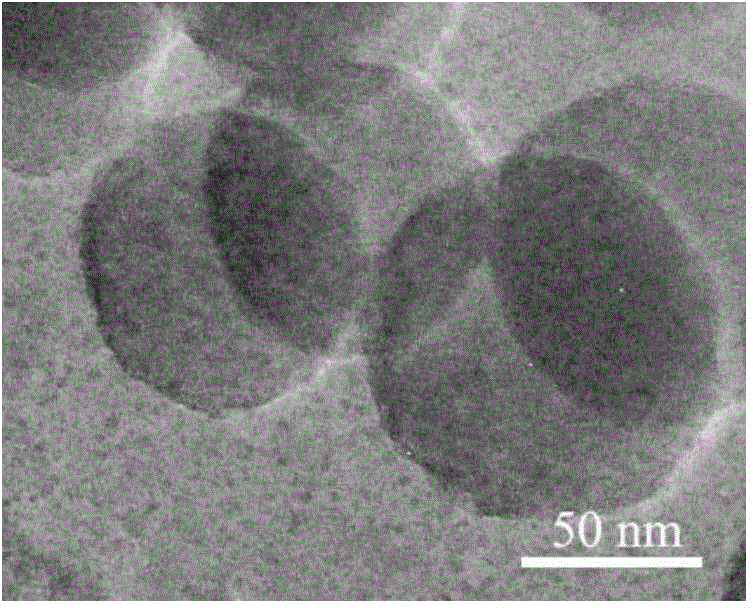

[0047] image 3 Shown is the transmission electron micrograph of the carbon spheres obtained in Example 3. It can be seen from the figure that the diameter of the carbon spheres is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com