A kind of method that loaded molecular sieve catalyzes toluene to synthesize o-chlorotoluene

A molecular sieve technology for catalyzing toluene and o-chlorotoluene, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unfavorable industrialization, harsh equipment requirements, strong corrosiveness, etc., and achieve easy product separation. , mild reaction conditions, high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of HZSM-5 molecular sieve

[0028] ① Preparation of ZSM-5 molecular sieve: 0.03 mol Al 2 (SO 4 ) 3 Added to the prepared 100 mL 1.5 mol / LH 2 S0 4 solution, stir to dissolve it completely, add 15 mL of ammonia water (mass fraction 25%) into 100 mL of distilled water, stir and mix evenly, slowly add this solution to the above Al 2 (SO 4 ) 3 / H 2 S0 4 In the solution, stir evenly to obtain solution A; add 150g of water glass (modulus 3.2) into 225 mL of distilled water, and stir evenly to obtain solution B; under stirring conditions, use a peristaltic pump to slowly add solution A to solution B reaction at 30 °C, after 2 h, put the mixture into a hydrothermal kettle, crystallize at 170 °C for 120 h, wash the prepared ZSM-5 molecular sieve with distilled water to neutrality, and dry it at 120 °C for 2 h, spare.

[0029] ② Preparation of HZSM-5 molecular sieve: 10 g of ZSM-5 molecular sieve and 100 mL NH 4 NO 3 (30wt%) solution was added to a 250 ...

Embodiment 2

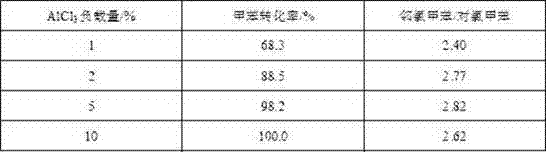

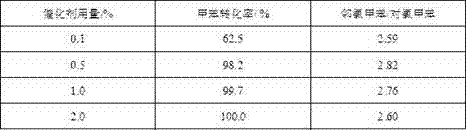

[0037] Adopt the same method of embodiment 1 to prepare AlCl 3 Load HZSM-5 molecular sieve, toluene chlorination reaction step is the same as embodiment 1, changes AlCl 3 The amount of loaded HZSM-5 molecular sieve is 0.05 g, 0.5 g, and 1.0 g, and the influence of catalyst amount on the toluene chlorination reaction process can be obtained, as shown in Table 2:

[0038] Table 2 Effect of catalyst dosage on toluene chlorination reaction

[0039]

[0040] Table 2 shows the effect of catalyst dosage on toluene chlorination reaction. As the amount of catalyst increased from 0.1% to 2.0%, the conversion rate of toluene increased from 62.5% to 100.0%; the ratio of o-chlorotoluene and p-chlorotoluene increased from 2.59 to 2.82, and then dropped to 2.60; as can be seen from Table 2 It is concluded that increasing the amount of catalyst is beneficial to increase the rate of toluene chlorination, but at the same time it will also lead to a decrease in the ratio of o-chlorotoluene to...

Embodiment 3

[0042] Adopt the same method of embodiment 1 to prepare AlCl 3 Loading HZSM-5 molecular sieve, the toluene chlorination reaction steps are the same as in Example 1, changing the reaction temperature to 50 °C and 80 °C, the influence of different reaction temperatures on the toluene chlorination process can be obtained, as shown in Table 3:

[0043] Table 3 Effect of different reaction temperatures on the chlorination of toluene

[0044] Reaction temperature / ℃ Toluene conversion / % o-Chlorotoluene / P-Chlorotoluene 50 86.4 2.59 65 98.2 2.82 80 100.0 2.50

[0045] Table 3 reflects the influence of reaction temperature on toluene chlorination reaction; as can be seen from Table 3, the conversion rate of toluene increases with the raising of reaction temperature. When the reaction temperature is 65 ℃, the ratio of o-chlorotoluene to p-chlorotoluene in the product is the highest, which is 2.82.

[0046] The results showed that high temperature wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com