Double-liquid-phase fermentation method of monascus yellow pigment by coupled in-situ fermentation-extraction

A technology of monascus yellow pigment and two-liquid phase, which is applied in the field of fermentation engineering, can solve the problems of unsuitable industrial production, low concentration of fermentation pigment, and long fermentation time, so as to improve permeability, shorten fermentation time, and reduce negative feedback The effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

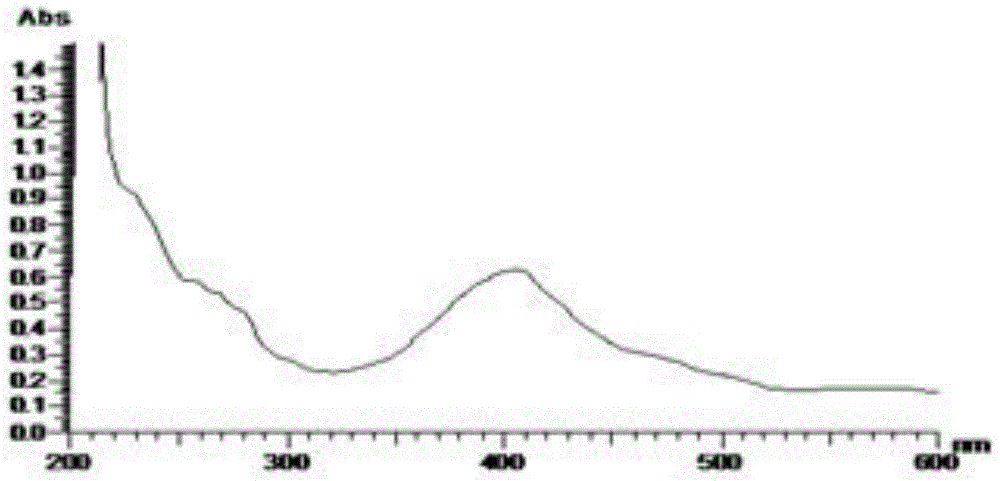

Image

Examples

Embodiment 1

[0030] Monascus JJLY-4A was selected as the shake flask strain. The fermentation medium consists of a minimal medium and an extract phase. Basic medium (g / L): corn starch 60, soybean powder 2, ammonium sulfate 8, NaNO36, yeast extract 0.2, corn steep liquor powder 0.2, zinc sulfate 0.2, magnesium sulfate 0.8, potassium dihydrogen phosphate 1.2; extract phase (with Volume ratio of medium): 10% soybean oil, 8% corn oil, 1% tricaprylic glyceride, 0.3% dicaprylic glyceride, and 0.2% caprylic glyceride. Except for soybean oil and corn oil in the extraction phase, the rest of the glycerides were added to the medium 48 hours after the fermentation started.

[0031] The liquid seeds of Monascus in the logarithmic growth phase were placed in a 500mL Erlenmeyer flask containing 100mL of fermentation medium at an inoculum volume of 10% by volume, and the shake flask was fermented at a speed of 180r / min and a temperature of 30°C. 5d. After the end, it is measured that the color value o...

Embodiment 2

[0033] The experimental procedure and fermentation medium are the same as those of the above-mentioned Example 1, except that the experimental strain is Monascus ZH6. Put the liquid seeds of Monascus in the logarithmic growth phase into a 500mL Erlenmeyer flask containing 100mL of fermentation medium at an inoculation volume of 10% by volume, and ferment in a shaker flask at a speed of 180r / min and a temperature of 30°C Culture 5d. After the end, it is measured that the color value of the monascus yellow pigment converted to the volume of the basic medium is between 160-170U / mL.

Embodiment 3

[0035] Monascus JJLY-4A was used as shake flask fermentation strain. It is basically the same as above-mentioned embodiment 1 step and culture medium formula, difference is: the cornstarch in the fermentation medium is 40g / L. Under the conditions of rotation speed of 180r / min and temperature of 30°C, shake flask fermentation culture was carried out for 5 days. After the end, it is measured that the color value of the monascus yellow pigment converted to the volume of the basic medium is between 150-160U / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com