Terminal structure of super-junction semiconductor device and manufacturing method thereof

A technology of superjunction semiconductor and terminal structure, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high process standard, difficult realization of manufacturing process, high complexity of terminal structure, low cost, High reliability and small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

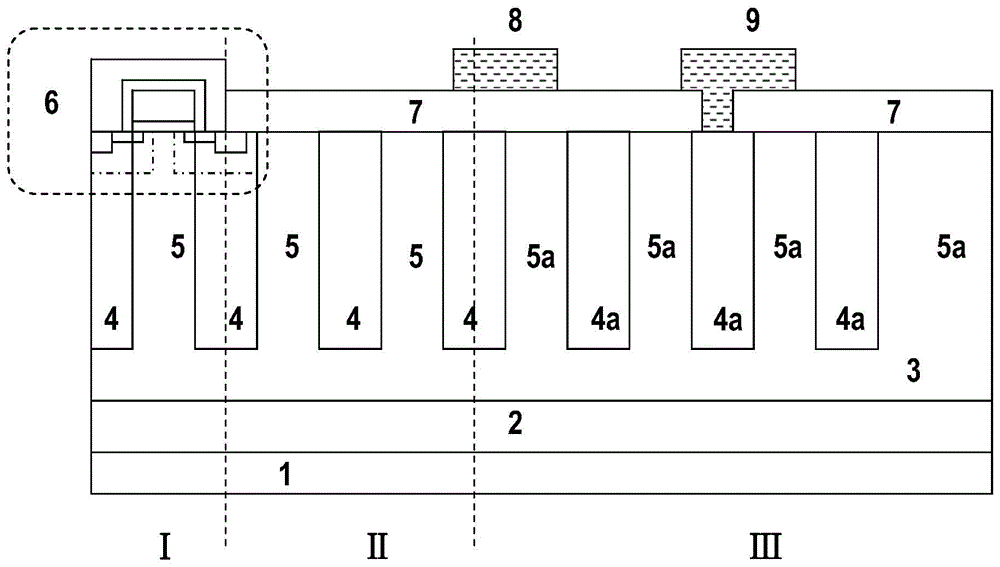

[0066] Such as figure 2 As shown, the terminal structure of the super junction semiconductor device of this embodiment has several super junction P columns, each super junction P column includes a top P column and a bottom P column, and the top P column in each super junction P column The width is not less than the width of the bottom P-pillar.

[0067] Among the several superjunction P columns, the top P columns located in the transition region of the terminal structure are connected to each other, and the spacing between the top P columns located in the terminal region of the terminal structure is along the transition away from the terminal structure The direction of the zone gradually widens.

[0068] Each top P-pillar is 2-6 microns in height. And the top P pillars of the plurality of super junction P pillars are formed by ion implantation and annealing activation.

Embodiment 2

[0070] Combine below Attached picture A method of manufacturing the terminal structure of the super junction semiconductor device of the second embodiment will be described. The manufacturing method of this embodiment is applicable to the epitaxial super junction structure. The flow of the manufacturing method of this embodiment picture Can refer to figure 1 9, the details are as follows.

[0071] Step 1, see image 3 , using an epitaxial process to epitaxially form a 3-15um N-type epitaxial layer 3-1 on the N-type heavily doped silicon substrate 2;

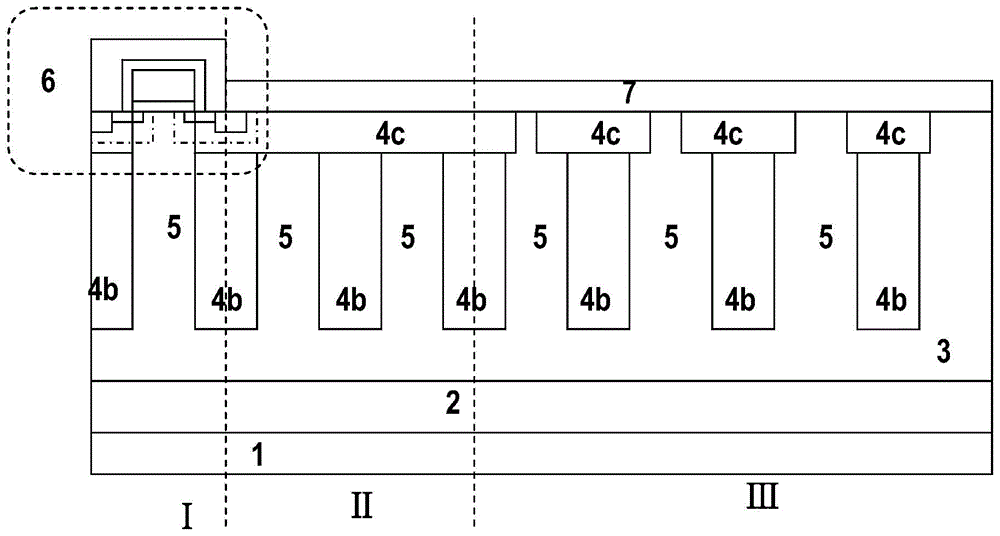

[0072] Step 2. Repeat the following operations several times until a bottom P-pillar with a preset height is obtained: first see Figure 4 As shown, use the designed bottom P-pillar mask to perform photolithography mask PR, P-type ion implantation 4b-1, and then see Figure 5 As shown, after degelling and cleaning, the epitaxy of the N-type epitaxial layer 3-2 is continued.

[0073] When the following operations ...

Embodiment 3

[0089] Combine below Attached picture A method of manufacturing the terminal structure of the super junction semiconductor device of the third embodiment will be described. The manufacturing method of this embodiment is applicable to a trench type super junction structure.

[0090] Step 1, see figure 1 4. Using an epitaxial process, an N-type epitaxial layer 3 of 10-100 microns is epitaxially grown on an N-type heavily doped silicon substrate 2;

[0091] Step two, see figure 1 5. Etching the deep trench 4d-1 required for the P-pillar by means of deep trench etching;

[0092] Step three, see figure 1 6. Fill the material 4d containing P-type impurities, such as P-type single crystal silicon epitaxy, and use chemical mechanical polishing (CMP) to flatten the silicon surface;

[0093] Step 4, see figure 1 6. Use the designed top P-pillar mask and photolithography mask to complete top P-type ion implantation 4c-1 and gel removal;

[0094] Step seven, see Figure 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com