Preparation method for flexible positive pole of lithium selenium battery

A battery and flexible technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the inability to effectively improve the shuttle effect of polyselenide in lithium-selenium batteries, and achieve easy implementation, mass production, and simple preparation methods. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 0.18g of multi-walled carbon nanotubes (10nm in diameter and 200nm in length) and 0.02g of sodium alginate were thoroughly ground in a mortar, then an appropriate amount of ultrapure water was added for wet grinding, and then the slurry was mixed with a spatula Coated on the fixed diaphragm, dried in vacuum for 12 hours and then cut into appropriate size for later use.

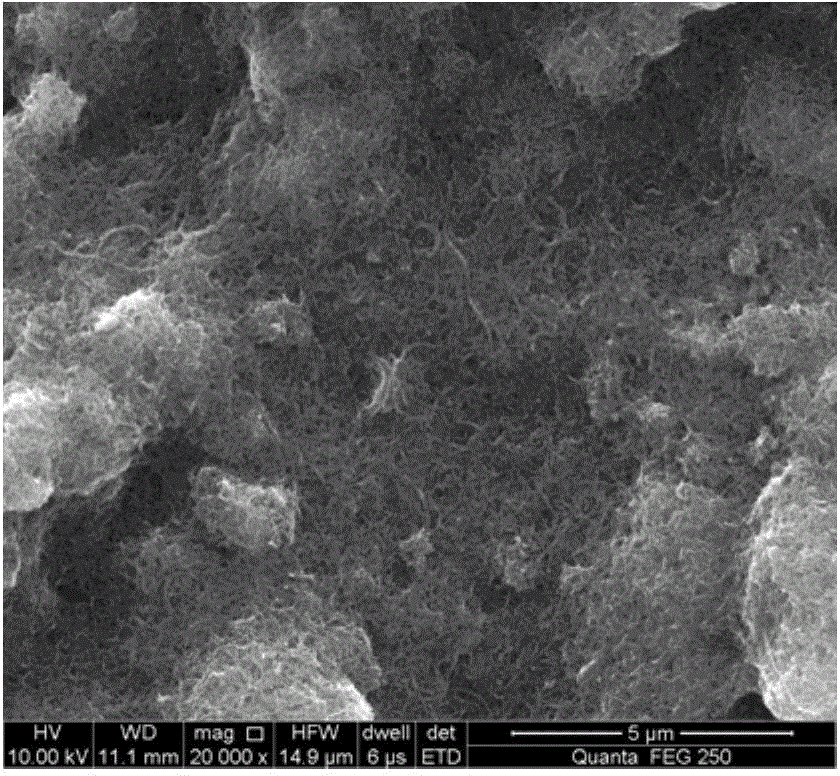

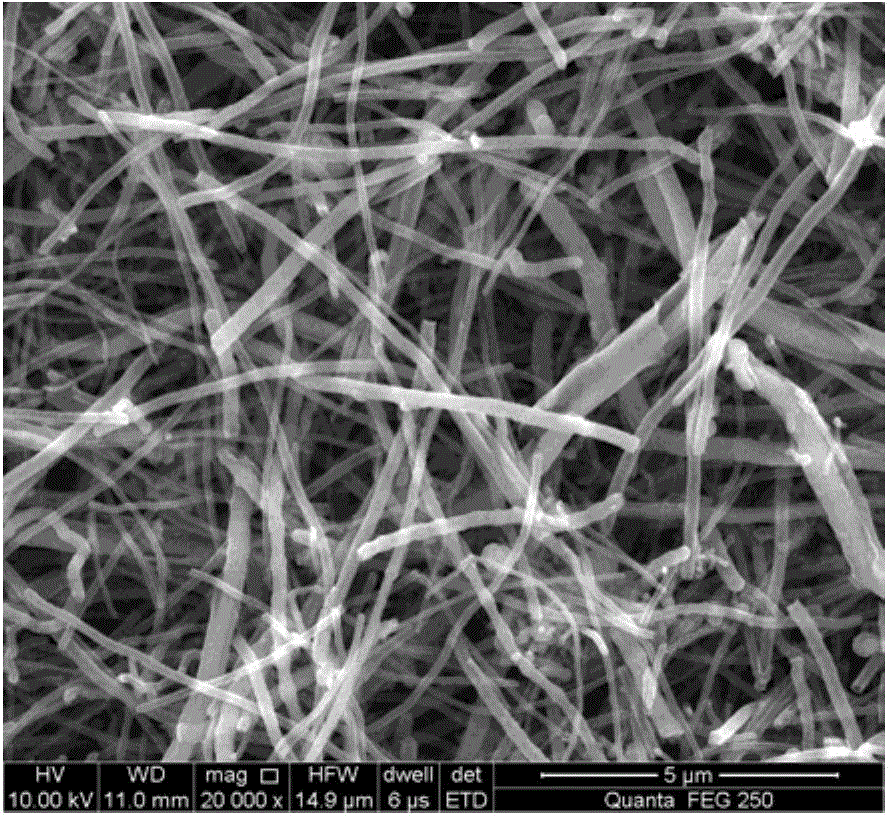

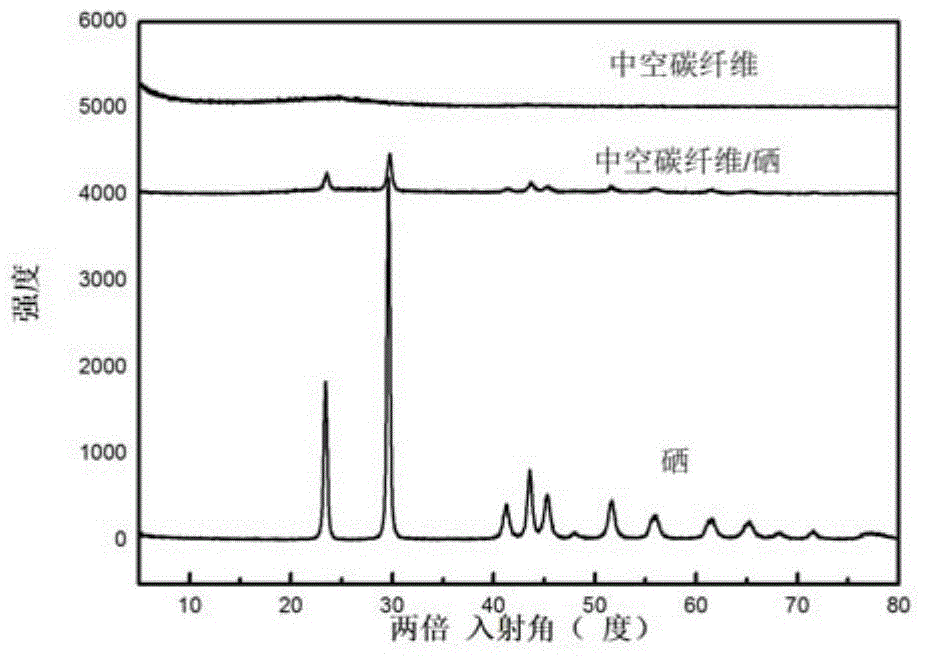

[0036] Prepare a mixed solution of 50 mL of concentrated nitric acid and 150 mL of concentrated sulfuric acid, add 1 g of hollow carbon fibers (40 nm in diameter and 10 μm in length) into the solution, stir magnetically for 5 hours, filter the product and wash three times with deionized water and ethanol respectively to obtain Activated hollow carbon fibers. Take 0.6 g of the activated hollow carbon fiber and 0.4 g of selenium powder, and after fully grinding, heat the sample at 260° C. without air for 12 hours to obtain a hollow carbon fiber and selenium composite material.

[0037] Take 75 mg of holl...

Embodiment 2

[0046] 0.18g of multi-walled carbon nanotubes (10nm in diameter and 200nm in length) and 0.02g of sodium alginate were thoroughly ground in a mortar, then an appropriate amount of ultrapure water was added for wet grinding, and then the slurry was mixed with a spatula Coated on the fixed diaphragm, dried in vacuum for 12 hours and then cut into appropriate size for later use.

[0047] Prepare a mixed solution of 50 mL of concentrated nitric acid and 150 mL of concentrated sulfuric acid, add 1 g of hollow carbon fibers (40 nm in diameter and 10 μm in length) into the solution, stir magnetically for 5 hours, filter the product and wash three times with deionized water and ethanol respectively to obtain Activated hollow carbon fibers. Take 0.6 g of activated hollow carbon fiber and 0.4 g of selenium powder, and after fully grinding, heat the sample at 260° C. without air for 12 hours to obtain hollow carbon fiber and selenium composite material.

[0048] Take 100 mg of hollow ca...

Embodiment 3

[0051] 0.18g of multi-walled carbon nanotubes (10nm in diameter and 200nm in length) and 0.02g of sodium alginate were thoroughly ground in a mortar, then an appropriate amount of ultrapure water was added for wet grinding, and then the slurry was mixed with a spatula Coated on the fixed diaphragm, dried in vacuum for 12 hours and then cut into appropriate size for later use.

[0052] Prepare a mixed solution of 50 mL of concentrated nitric acid and 150 mL of concentrated sulfuric acid, add 1 g of hollow carbon fibers (40 nm in diameter and 10 μm in length) into the solution, stir magnetically for 5 hours, filter the product and wash three times with deionized water and ethanol respectively to obtain Activated hollow carbon fibers. Take 0.5 g of activated hollow carbon fiber and 0.5 g of selenium powder, and after fully grinding, heat the sample at 260° C. without air for 12 hours to obtain hollow carbon fiber and selenium composite material.

[0053] Take 60 mg of hollow car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com