Preparation method and application of organic liquid separation net film based on wettability differences

An organic liquid and ophthalmic membrane technology, applied in the field of organic liquid separation ophthalmic membrane preparation, can solve the problems of intolerance to organic solvents, inability to achieve organic liquid separation, restricting the development and application of organic liquid separation technology, and achieves low cost and good separation. Effect, preparation method Simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

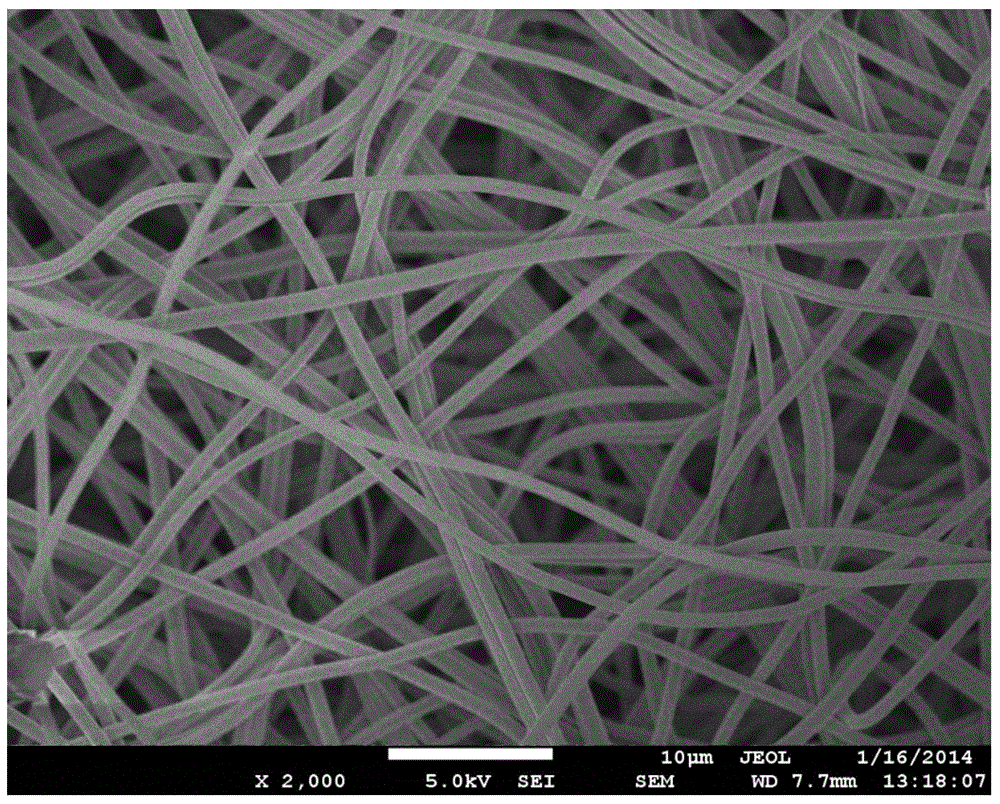

[0046] (1) Put 4 grams of PVP (molecular weight: 1,300,000), 20 grams of ethanol, and 4 grams of acetic acid in a 50-ml Erlenmeyer flask, and stir for 1 to 2 hours to form a uniform and transparent solution. Then 7 grams of tetrabutyl titanate and 5 grams of ethyl orthosilicate were added, and stirred for another 24 hours to form an electrospinning solution.

[0047](2) Electrospinning device As shown in the attached figure, connect the electrospinning solution to a 9# flat-headed electrospinning needle (1 mm inner diameter) through a syringe pump, a syringe, and an extension tube. The positive electrode of the high-voltage power supply is connected to the electrospinning needle, and the negative electrode is connected to aluminum foil as a fiber receiving plate. Under the action of high-voltage electric field, the electrospinning solution is stretched and solidified to form fibers, which are collected on the receiving plate. The working parameters of electrospinning were as ...

Embodiment 2

[0053] (1) Put 4 grams of PVP (molecular weight: 1,300,000), 20 grams of ethanol, and 4 grams of acetic acid in a 50-ml Erlenmeyer flask, and stir for 1 to 2 hours to form a uniform and transparent solution. Then 7 grams of tetrabutyl titanate and 5 grams of ethyl orthosilicate were added, and stirred for another 24 hours to form an electrospinning solution.

[0054] (2) Electrospinning device As shown in the attached figure, connect the electrospinning solution to a 9# flat-headed electrospinning needle (1 mm inner diameter) through a syringe pump, a syringe, and an extension tube. The positive electrode of the high-voltage power supply is connected to the electrospinning needle, and the negative electrode is connected to aluminum foil as a fiber receiving plate. Under the action of high-voltage electric field, the electrospinning solution is stretched and solidified to form fibers, which are collected on the receiving plate. The working parameters of electrospinning were as...

Embodiment 3

[0060] (1) Put 4 grams of PVP (molecular weight: 1,300,000), 20 grams of ethanol, and 4 grams of acetic acid in a 50-ml Erlenmeyer flask, and stir for 1 to 2 hours to form a uniform and transparent solution. Then 7 grams of tetrabutyl titanate and 5 grams of ethyl orthosilicate were added, and stirred for another 24 hours to form an electrospinning solution.

[0061] (2) Electrospinning device As shown in the attached figure, connect the electrospinning solution to a 9# flat-headed electrospinning needle (1 mm inner diameter) through a syringe pump, a syringe, and an extension tube. The positive electrode of the high-voltage power supply is connected to the electrospinning needle, and the negative electrode is connected to aluminum foil as a fiber receiving plate. Under the action of high-voltage electric field, the electrospinning solution is stretched and solidified to form fibers, which are collected on the receiving plate. The working parameters of electrospinning were as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com