Highly dispersed highly stable high concentration and high yield graphene dispersion liquid and preparation method thereof

A kind of graphene dispersion liquid, graphene technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

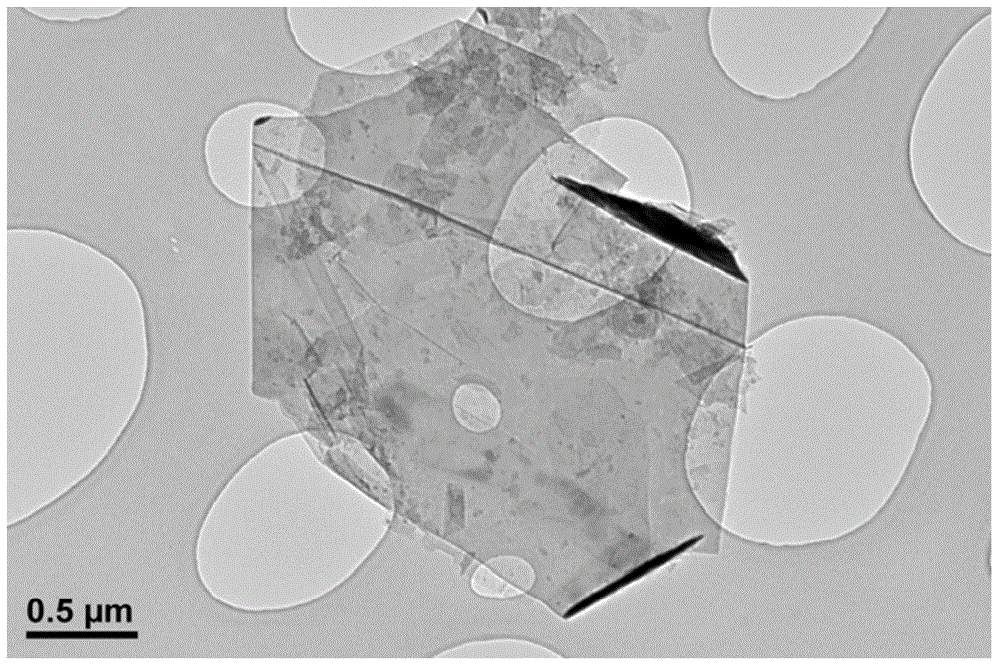

Image

Examples

Embodiment 1

[0029] (1) Take 10 g of raw materials for preparing graphite powder.

[0030] (2) Add 0.5 g of sodium p-styrene sulfonate into 180 mL of N-methylpyrrolidone, and stir for 15 min until completely dissolved.

[0031] (3) Mix the graphite powder raw material in step 1 with the solution in step 2 to form a uniform mixture.

[0032] (4) Take the mixed solution in step (3) and add it to the grinding equipment with balls, rods or segments as the medium, and grind for 10 hours to obtain oligolayer graphene with a concentration of 50 mg / mL.

[0033] The raw materials are: graphite, expandable graphite, and primary expanded graphite.

[0034] The dispersant is: sodium dodecylbenzenesulfonate, sodium dodecylsulfonate, sodium p-styrenesulfonate, sodium polystyrenesulfonate, sodium ligninsulfonate, dodecylsulfuric acid One or two of sodium, polyvinylpyrrolidone, sodium cholate, polystyrene, cetyltrimethylammonium bromide, polyvinyl alcohol, and Tween 80.

[0035] The solvent is water, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com