System and method for synthesis of tri-n-butyl citrate through continuous esterification

A technology for tri-n-butyl ester and a synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of limited output in a single workshop, difficulty in safe production, and many sets of equipment, and achieves enhanced Market competitiveness, improving the utilization rate of raw materials, and reducing the effect of the three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

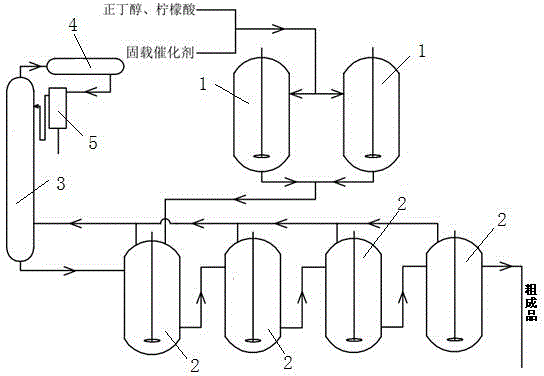

[0029] Example 1: A continuous esterification synthesis of tri-n-butyl citrate system, including dissolving tank 1, esterification tank 2, dehydration tower 3, condenser 4, oil-water separator 5, dissolving tank 1 is set to two, dissolving Tank 1 is connected to 4 esterification tanks 2 connected in series, esterification tank 2 is connected to dehydration tower 3, the top outlet of dehydration tower 3 is connected to condenser 4, condenser 4 is connected to oil-water separator 5, and oil-water separator 5 is connected to dehydration Near the upper end of the tower 3, the bottom of the dehydration tower 3 is connected to the first esterification kettle 2. The operation procedure includes the following steps:

[0030] a. Mix and dissolve citric acid, n-butanol and catalyst in the mixing and dissolving tank 1. The molar ratio of citric acid and n-butanol is generally 1:4, and the catalyst is added in an appropriate amount according to production needs;

[0031] b. Add the mixed liqui...

Embodiment 2

[0036] Example 2: Take a 50,000 tons / year TBC production device as an example.

[0037] Refer to the system of Example 1:

[0038] 1. Design the volume and heating area of each esterification vessel, the diameter of the esterification dehydration tower and the height of the packing (or the number of trays), the size and form of the condenser, the specifications of the oil-water separator, etc., and consider the appropriate margin to build 50,000 tons / Year TBC continuous esterification unit.

[0039] 2. Configure a mixed solution of citric acid and n-butanol in a ratio of 1:4.5 (molar ratio) and add an appropriate amount of catalyst. Add the mixed solution (according to the corresponding acid content) into the No. 1 esterification kettle at a constant speed and heat it with steam.

[0040] 3. Turn on the standby butanol pump to add proper butanol to the first esterification kettle, and adjust the steam consumption of each esterification kettle, and control the temperature of each ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com