Refiner for aluminum alloy and preparation method

A technology of refiner and aluminum alloy, which is applied in the field of aluminum alloy refiner, can solve the problems of increasing the cost of alloy manufacturing and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

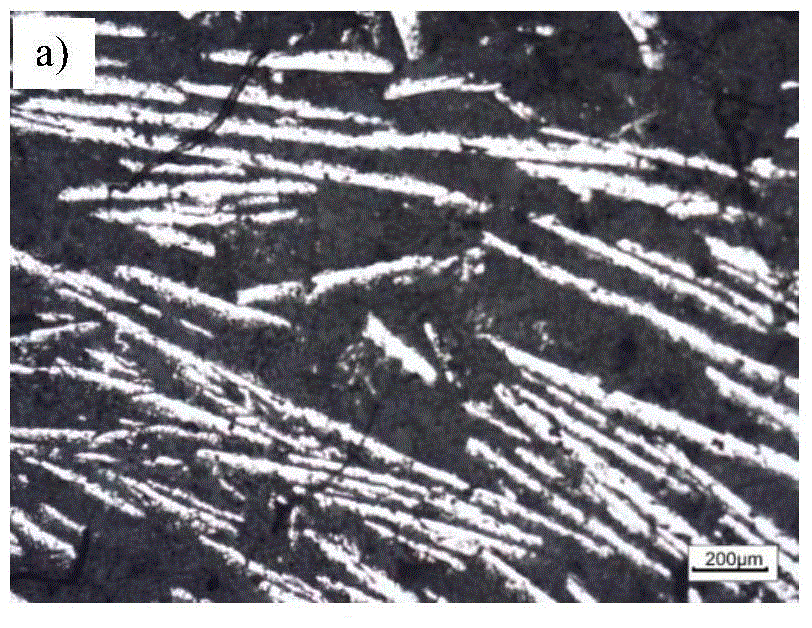

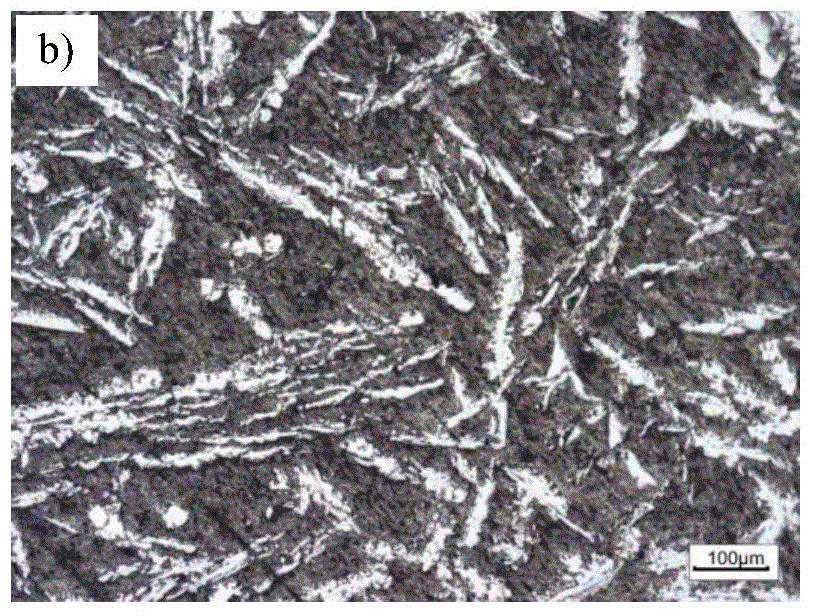

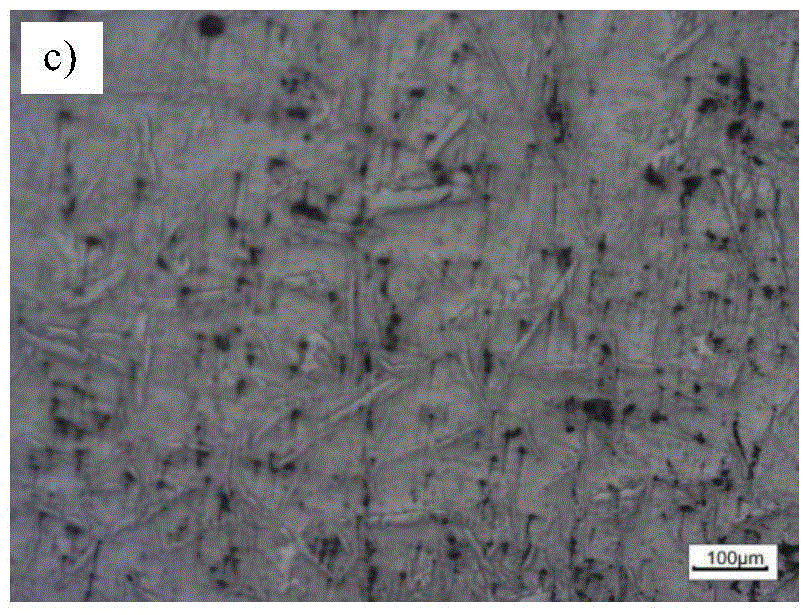

Image

Examples

Embodiment Construction

[0024] The following examples describe the present invention in more detail.

[0025] According to the weight ratio of 4.5-5.5% titanium, 0.2-0.4% cerium, 0.6-1.8% magnesium and the balance of aluminum, in N 2 and SF 6 The smelting is carried out under a protective atmosphere. The smelting is carried out in an induction furnace. During smelting, the voltage is controlled at 300-400V, the current is controlled at 100-120A, and the melting temperature is 1200°C-1300°C. During the smelting process, first add pure aluminum ingots, After it melts, wrap it with aluminum foil, and use a bell jar to press the titanium powder under the liquid surface of the aluminum melt. After adding the titanium powder, stand still for ten minutes, and use a graphite bell jar to put Mg-30Ce (containing Mg element 70wt%, The master alloy containing 30wt% Ce element) is pressed under the liquid surface of the aluminum alloy melt, and after standing still for five minutes, the alloy melt is stirred by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com