Fermented liquid suckling pig feed and preparation method thereof

A technology for suckling pig feed and pig feed, which is applied in the field of fermented liquid suckling pig feed and its preparation, can solve problems such as unfavorable health and growth and development of piglets, unsuitable requirements for energy saving, large gap between solid feed and breast milk, etc. Palatability and digestibility, reduced diarrhea rate, good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

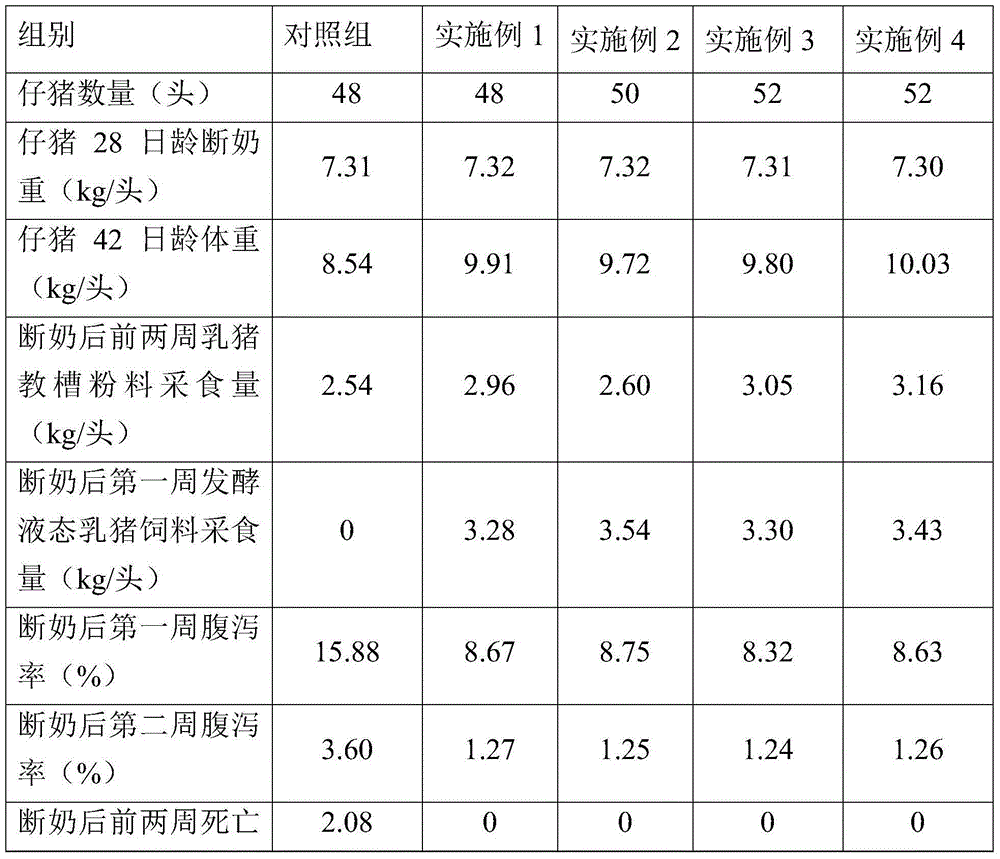

Examples

Embodiment 1

[0022] As an embodiment of the present invention, the preparation method of described fermented liquid suckling pig feed comprises the following steps:

[0023] (1) First-level slant cultivation:

[0024] The lactic acid bacteria are transferred to the slant of the MRS medium, and cultured at 30-37° C. for 16-24 hours.

[0025] Saccharomyces cerevisiae was transferred to the slant of YPD medium, and cultured at 28-36° C. for 16-26 hours.

[0026] In this embodiment, the Saccharomyces cerevisiae is Saccharomyces cerevisiae Sa-10, which is preserved in China General Microorganism Culture Collection and Management Center, and the preservation number is CGMCC No.6120. The lactic acid bacteria are Lactobacillus plantarum.

[0027] (2) Two-stage liquid culture:

[0028] Inoculate the lactic acid bacteria slant obtained in step (1) into the liquid medium, seal it with a sterile sealing film, place it in a constant temperature incubator, and culture it statically at 32-36°C for 12-...

Embodiment 2

[0040] As an embodiment of the present invention, the preparation method of described fermented liquid suckling pig feed comprises the following steps:

[0041] (1) First-level slant cultivation:

[0042] The lactic acid bacteria are transferred to the slant of the MRS medium, and cultured at 30-37° C. for 16-24 hours.

[0043] Saccharomyces cerevisiae was transferred to the slant of YPD medium, and cultured at 28-36° C. for 16-26 hours.

[0044] In this embodiment, the Saccharomyces cerevisiae is Saccharomyces cerevisiae Sa-10, which is preserved in China General Microorganism Culture Collection and Management Center, and the preservation number is CGMCC No.6120. The lactic acid bacteria are Lactobacillus plantarum.

[0045] (2) Two-stage liquid culture:

[0046] Inoculate the lactic acid bacteria slant obtained in step (1) into the liquid medium, seal it with a sterile sealing film, place it in a constant temperature incubator, and culture it statically at 32-36°C for 12-...

Embodiment 3

[0058] As an embodiment of the present invention, the preparation method of described fermented liquid suckling pig feed comprises the following steps:

[0059] (1) First-level slant cultivation:

[0060] The lactic acid bacteria are transferred to the slant of the MRS medium, and cultured at 30-37° C. for 16-24 hours.

[0061] Saccharomyces cerevisiae was transferred to the slant of YPD medium, and cultured at 28-36° C. for 16-26 hours.

[0062] In this embodiment, the Saccharomyces cerevisiae is Saccharomyces cerevisiae Sa-10, which is preserved in China General Microorganism Culture Collection and Management Center, and the preservation number is CGMCC No.6120. The lactic acid bacteria are Lactobacillus plantarum.

[0063] (2) Two-stage liquid culture:

[0064] Inoculate the lactic acid bacteria slant obtained in step (1) into the liquid medium, seal it with a sterile sealing film, place it in a constant temperature incubator, and culture it statically at 32-36°C for 12-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com