Bismuth tungstate nanocomposite, and preparation method and application thereof

A nanocomposite material, bismuth tungstate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low photoelectric conversion efficiency and catalytic performance, to improve photocatalytic performance, The effect of strong photocatalytic performance and good photoelectrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of bismuth tungstate nanocomposite material of the present invention is as follows:

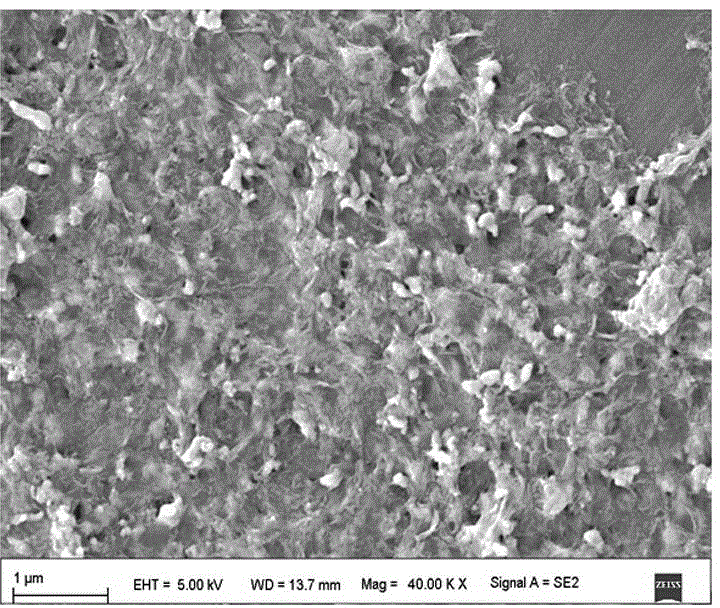

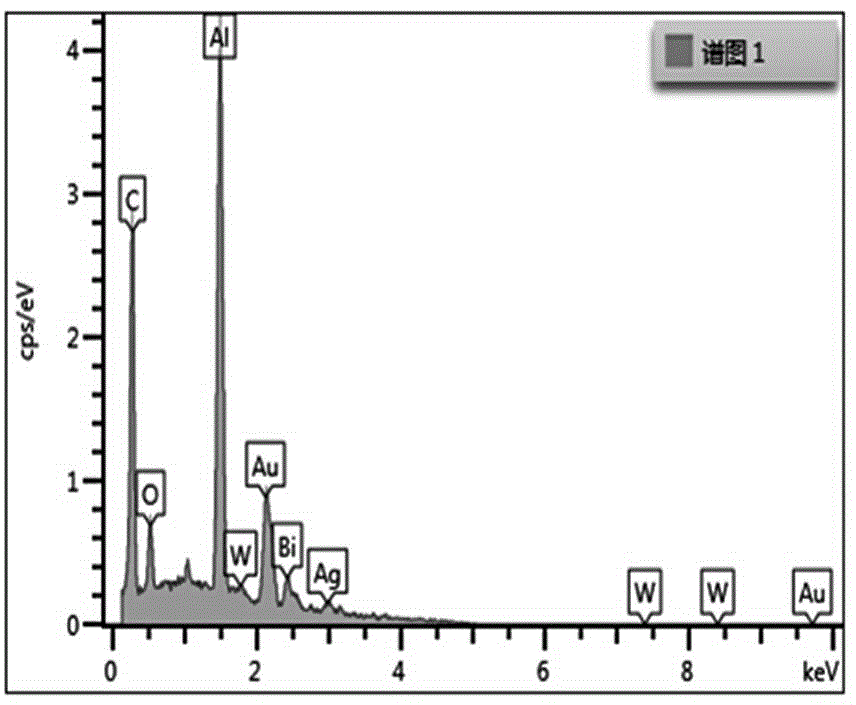

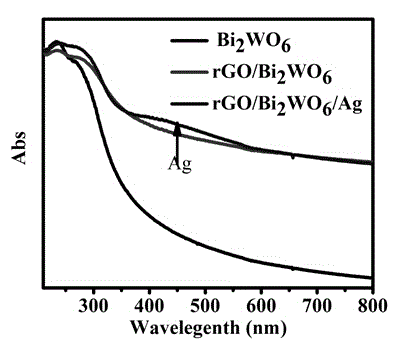

[0035] (1) Weigh 0.4mM Na 2 WO 6 2H 2 O and 2.2mM sodium oleate were dissolved in 20mL double-distilled water respectively, and then ultrasonically dissolved to form a transparent liquid marked as A liquid; weigh 0.4mM Bi(NO 3 ) 3 ·5H 2 O, add 10mL of dispersed graphene oxide (GO) with a mass concentration of 1mg / mL, and add 10ml of twice distilled water for ultrasonication to form a brown uniform liquid marked as B liquid, then mix A and B for 3 hours . where Na 2 WO 6 2H 2 O is the tungsten source, Bi(NO 3 ) 3 ·5H 2O is a bismuth source. Then the above mixed liquid was transferred to a sealed autoclave, put the autoclave into an oven, control the reaction temperature to 160°C, and after 18 hours of hydrothermal reaction, take out the autoclave and cool for 30 minutes. A black precipitate was obtained by filtration with a 45 μm mixed cellulose memb...

Embodiment 2

[0039] Embodiment 2 Performance test of the bismuth tungstate nanocomposite material of the present invention

[0040] The rGO / Bi prepared in Example 1 2 WO 6 / Ag nanocomposite material was dried at 60° C. for 6 h, and after drying, 5 mg of the composite material was weighed and dispersed in 10 mL of absolute ethanol. Finally, use a dropper to draw a certain amount of composite material and drop-coat it on the surface of ITO conductive glass, and dry it in an oven at 60°C. Then it was put into a tube furnace and raised to 300°C with a heating rate of 1°C / min, and kept at 300°C for 1.5 hours.

[0041] 1. After taking out the conductive glass, put it in the self-made electrolytic cell, and then make the current-time curve on the CHI900 scanning electrochemical microscope, the electrolyte used is 0.25mol / LNa 2 S and 0.35mol / LNa 2 SO 3 , the bias voltage used is 0.1V, and the time of optical switching is 10 seconds. A three-electrode system is adopted, the working electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com