Preparation method of zirconium-containing solid super acid

A technology of solid super acid and zirconium source, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of sulfuric acid concentration limitation, poor hydrothermal stability, high temperature resistance, etc., to achieve acidity and The effect of uniformity improvement, good hydrothermal stability, and good hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

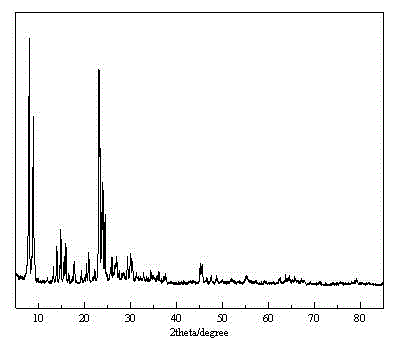

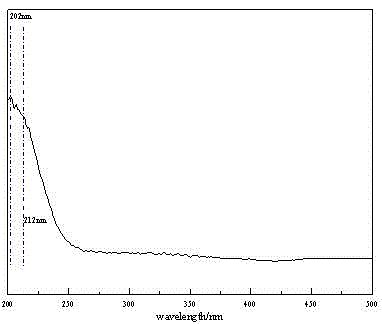

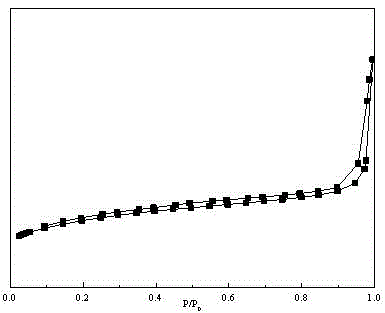

Embodiment 1

[0055] Take 38g of tetrapropylammonium hydroxide solution with a mass fraction of 23.5% and mix it with 55g of water, stir at 60°C for about 0.5h, then add 39g of ethyl orthosilicate dropwise to the mixture; after the dropwise addition, set the temperature At 80°C, start timing from temperature adjustment, remove alcohol for 7 hours, add water to maintain the volume of the solution; pour out the liquid, add water to 114g, and then crystallize at 200°C for three days; centrifuge, wash, and Dry to obtain the pure silicon molecular sieve S-1 containing the template agent in the channel. Mix 5g of the above-mentioned S-1 molecular sieve with 13.0g of tetrapropylammonium hydroxide solution with a mass fraction of 23.5% and 80g of ethanol, stir and mix thoroughly at 40°C; then dissolve 2.8g of tetrabutyl zirconate in 50g of ethanol, slowly Add dropwise to the above mixed solution, carry out template ion exchange at 40°C for 10h; then filter out the solid, wash, dry, and roast at 500...

Embodiment 2

[0058] Take 38g of tetrapropylammonium hydroxide solution with a mass fraction of 23.5% and mix it with 55g of water, stir at 60°C for about 0.5h, then add 39g of ethyl orthosilicate dropwise to the mixture; after the dropwise addition, set the temperature At 80°C, start timing from temperature adjustment, remove alcohol for 7 hours, add water to maintain the volume of the solution; pour out the liquid, add water to 114g, and then crystallize at 200°C for three days; centrifuge, wash, and Dry to obtain the pure silicon molecular sieve S-1 containing the template agent in the channel. Mix 5g of the above S-1 molecular sieve with 9g of tetrapropylammonium hydroxide solution with a mass fraction of 23.5% and 150g of isopropanol, stir and mix thoroughly at 70°C; then dissolve 4g of tetrabutyl zirconate in 50g of isopropanol , slowly added dropwise to the above mixture, and carried out template ion exchange at 70°C for 20h; then filtered out the solid, washed, dried, and roasted at...

Embodiment 3

[0060] Take 38g of tetrapropylammonium hydroxide solution with a mass fraction of 23.5% and mix it with 55g of water, stir at 60°C for about 0.5h, then add 39g of ethyl orthosilicate dropwise to the mixture; after the dropwise addition, set the temperature At 80°C, start timing from temperature adjustment, remove alcohol for 7 hours, add water to maintain the volume of the solution; pour out the liquid, add water to 114g, and then crystallize at 200°C for three days; centrifuge, wash, and Dry to obtain the pure silicon molecular sieve S-1 containing the template agent in the channel. Mix 5g of the above S-1 molecular sieve with 15.8g of tetrapropylammonium bromide solution with a mass fraction of 23.5% and 200g of ethanol, stir and mix thoroughly at 70°C; then dissolve 6g of zirconium nitrate pentahydrate in 50g of ethanol, slowly drop In the above mixed solution, template ion exchange was carried out at 90°C for 30h; then the solid was filtered out, washed, dried, and calcine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com